Vibration penetrating lunar soil coring device with spiral assisted submersion

A coring and spiral technology, applied in the field of manual sampling of the manned spaceflight lunar surface, can solve problems such as poor sampling ability, achieve the effect of increasing the heart rate, improving the diving efficiency, and optimizing the sampling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

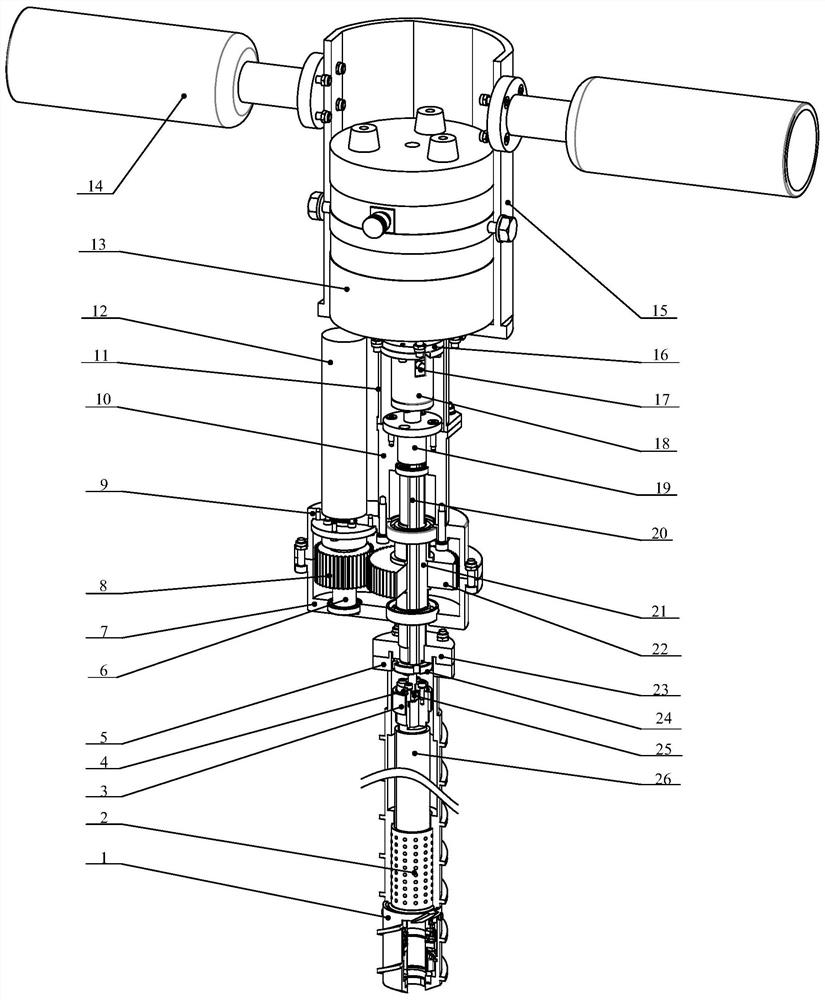

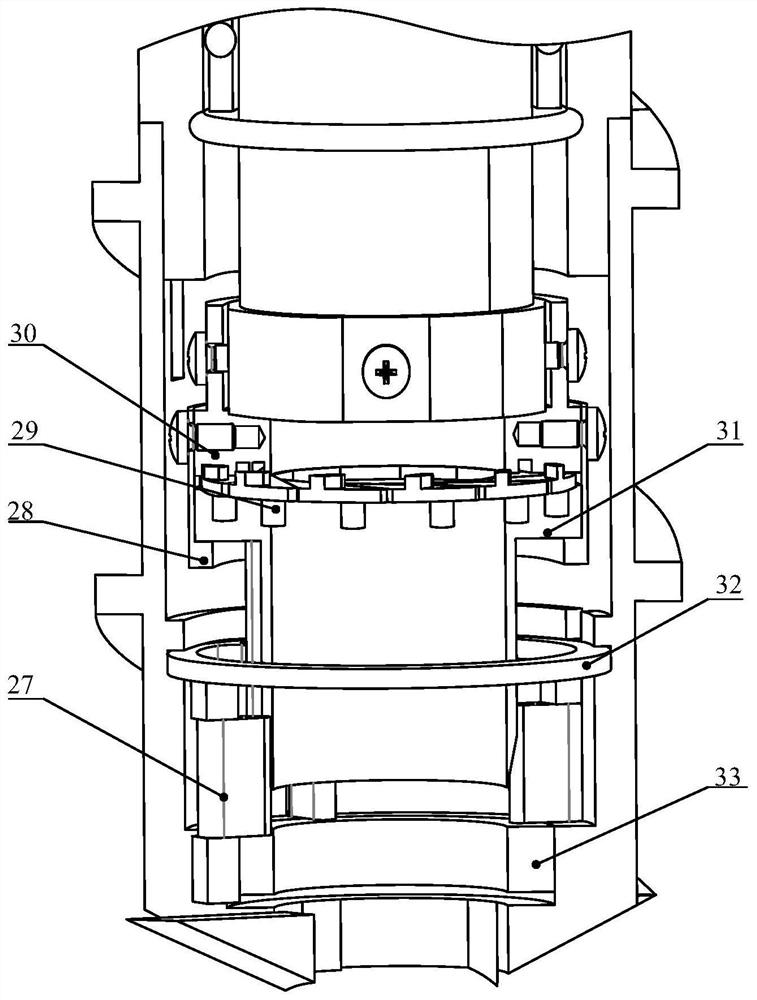

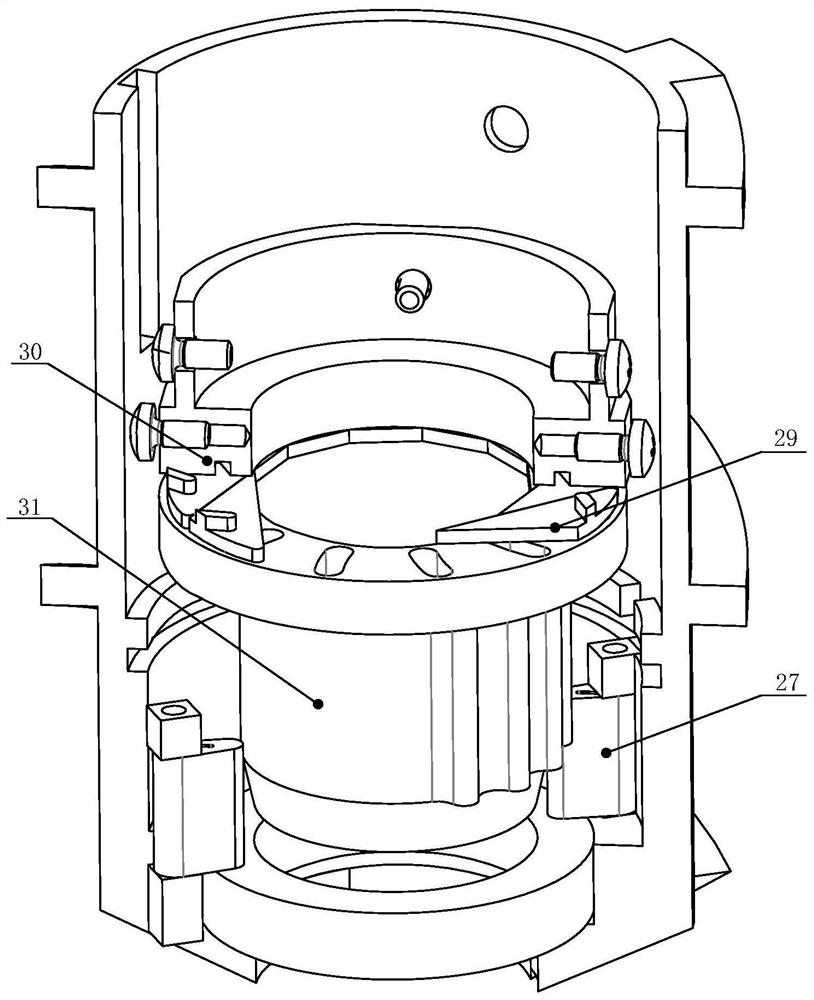

[0022] Specific implementation mode one: the following combination Figure 1 to Figure 5 Describe this embodiment, the vibrating penetrating lunar soil coring device described in this embodiment, which assists in submersion, includes a support mechanism, a vibrating coring mechanism, a spiral soil discharge mechanism and a sealing mechanism,

[0023] The support mechanism is used to provide a support frame for the vibrating coring mechanism and the spiral soil discharge mechanism;

[0024] Vibration coring mechanism includes electromagnetic exciter 13, vibration output flange 16, accelerometer 17, accelerometer bracket 18, linear bearing 19, vibrating ejector rod 20, coring tube 26, vibration connecting flange 4, locking nut 3. Steel ball cage 2 and nut 25,

[0025] The electromagnetic exciter 13 is installed on the supporting mechanism,

[0026] The output shaft of the electromagnetic exciter 13 is connected to the accelerometer bracket 18 through the vibration output flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com