Solvent-based gravure inks, prints and laminated products for laminates

A kind of gravure printing ink, solvent-based technology, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of delayed operation, printing can not continue, etc., to achieve excellent gravure printing printability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

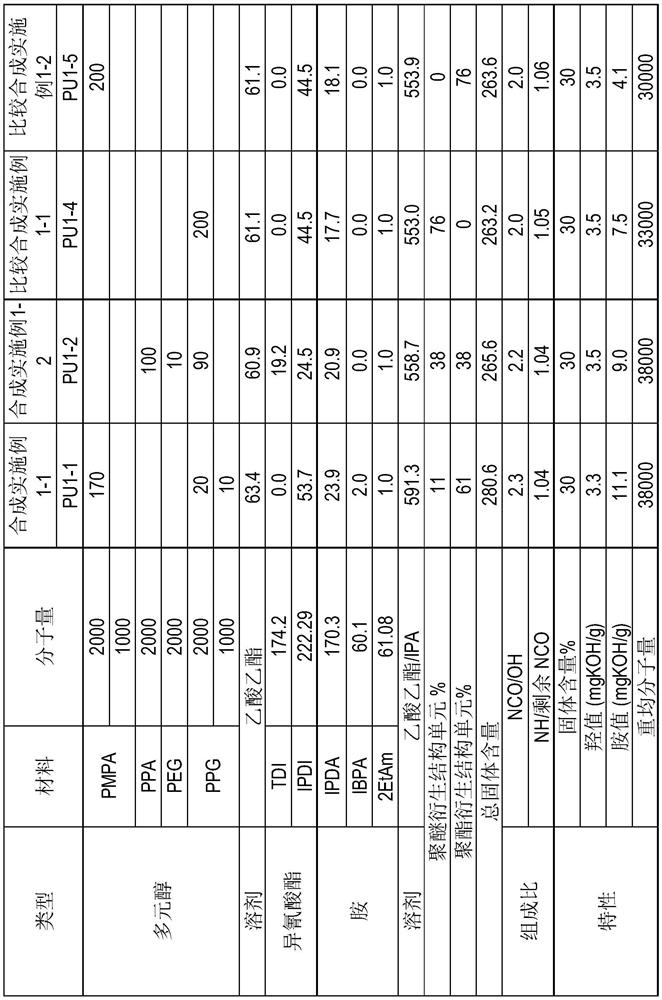

[0195] Hereinafter, the present invention will be described in detail through examples, however, the present invention is not limited to these examples. It should be noted that, unless otherwise specified, "parts" and "%" in this section represent "parts" and mass percentage in the sense of mass, respectively.

[0196] (hydroxyl value)

[0197] Hydroxyl value refers to the value obtained after converting the amount of hydroxyl in 1g of resin into mg of potassium hydroxide. The calculation of the amount of hydroxyl is by first esterifying or acetylating the hydroxyl in the resin with an excess of anhydrous acid. The remaining acid was then back titrated with base. The hydroxyl value is measured in accordance with JIS K 0070 (1992).

[0198] (amine value, acid value)

[0199] The amine value means the number of mg of potassium hydroxide equivalent to the amount of hydrochloric acid required to neutralize the amino groups contained in 1 g of the resin. Acid value refers to th...

Embodiment 2-3

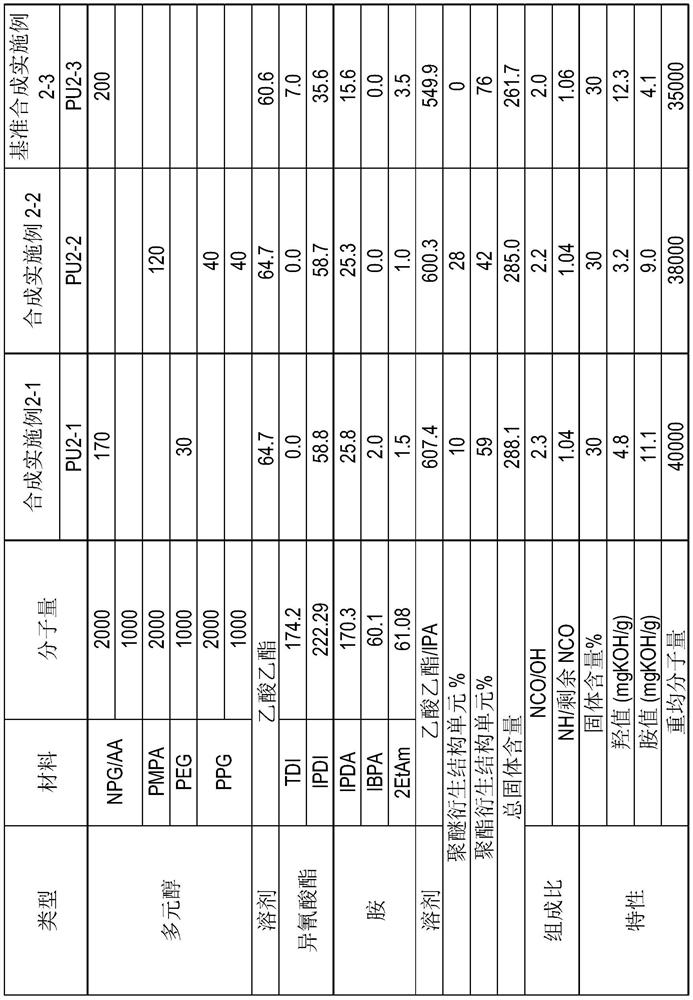

[0233] (Synthesis Example 2-2 and Reference Synthesis Example 2-3) [Polyurethane Resins PU2-2 and PU2-3]

[0234] Polyurethane resin solutions PU2-2 and PU2-3 were synthesized in a similar manner to Synthesis Example 2-1, the difference being that the raw materials shown in Table 1-2 were used. In Table 1-2, PMPA, PPG and TDI represent the following compounds:

[0235] PPA: Polyester polyol formed by condensation of 3-methyl-1,5-pentanediol and adipic acid

[0236] PPG: polypropylene glycol

[0237] TDI: Toluene diisocyanate (methyl-1,3-phenylene diisocyanate)

[0238] (Synthesis Example 3-1) [vinyl chloride-acrylic acid copolymer resin PVAc1]

[0239] In a 1.0L autoclave, 1.0g of potassium persulfate (K 2 S 2 o 8) was dissolved in 500g of ion-exchanged water and the solution obtained was allowed to stand for degassing. After raising the temperature to 60° C., 425 g of sodium di(2-ethylhexyl) sulfosuccinate (trade name: Aerosol OT) consisting of 357 g of vinyl chloride,...

Embodiment 1-1

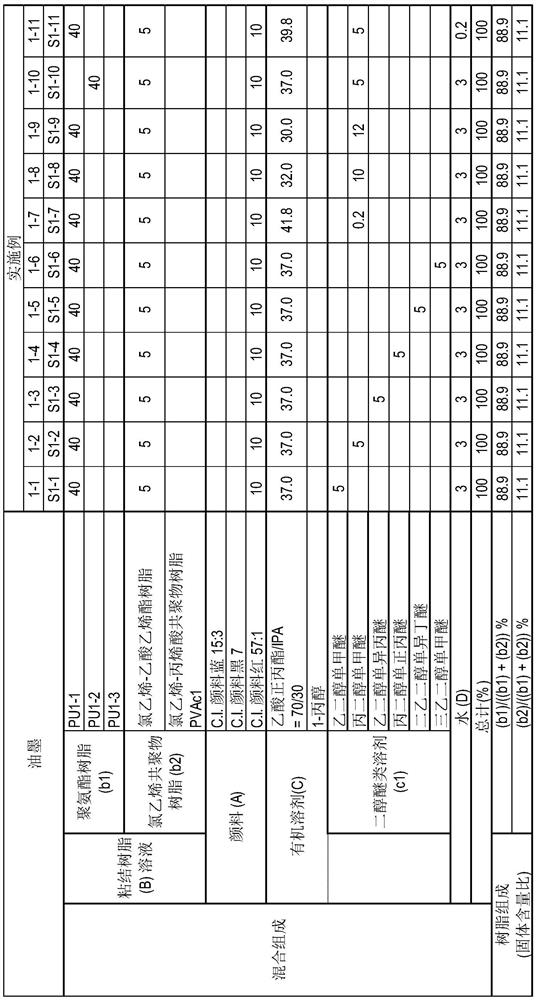

[0242] (Example 1-1) [Preparation of solvent type gravure ink S1-1 for laminate]

[0243] 40 parts of polyurethane resin solution PU1-1 (solid content: 30%), 5.0 parts of vinyl chloride-vinyl acetate copolymer resin solution (Nissin Chemical Industry Co., Ltd.) The prepared SOLBIN TAO, vinyl chloride: vinyl acetate: vinyl alcohol (mass ratio) = 91:2:7, solid content of ethyl acetate solution is 30%), 10 parts of C.I. Pigment Red 57:1 (azo lake red pigment) and 37 parts of n-propyl acetate / IPA solution in a mixing ratio of 70 / 30 were mixed and dispersed for 30 minutes. Subsequently, 5.0 parts of ethylene glycol monomethyl ether and 3.0 parts of water were added and mixed among the above under stirring with a disperser to obtain a solvent type gravure ink S1-1 for a laminate. The composition of the mixture is shown in Table 3-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com