Film-forming aid and preparation method thereof

A film-forming aid and catalyst technology, applied in the direction of ether preparation, alkylene oxide preparation ether, chemical instruments and methods, etc., can solve the problems of safety and environmental protection limitations, performance impact, high volatility, etc., and achieve broad market prospects, VOC Effect of low emission and excellent film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

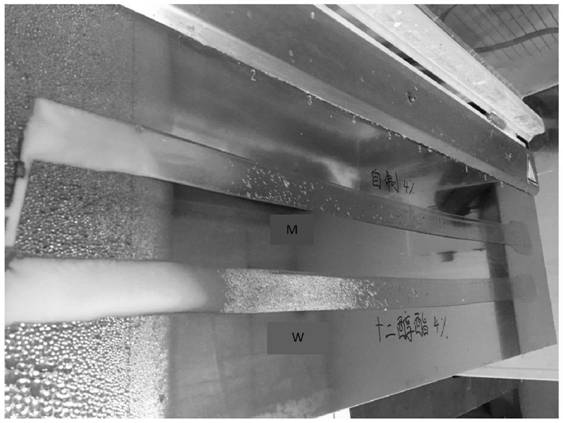

Image

Examples

preparation example Construction

[0060] The second aspect of the present invention provides a kind of preparation method of above-mentioned film-forming aid, comprises the steps:

[0061] (1) will React with catalyst I at 60-200°C for 1-4h;

[0062] (2) Add catalyst II and react at 60-200° C. for 3-7 hours to obtain the film-forming aid.

[0063] In one embodiment, the preparation method of the film-forming aid comprises the steps of:

[0064] (1) will React with Catalyst I at 90°C for 4h;

[0065] (2) Add catalyst II and react at 120° C. for 4 hours to obtain the film-forming aid.

[0066] The present invention adopts It is a reactant, and adopts boron trifluoride, sodium alkoxide or a mixture of hydroxide and quaternary ammonium salt as a catalyst, and the film-forming aid prepared by step-by-step catalytic reaction has good compatibility with any polymer emulsion. Does not cause demulsification during production, especially when R 3 When it is methyl or ethyl, and R4 is n-propyl and n-butyl, it c...

Embodiment 1

[0076] Embodiment 1 provides a kind of film-forming aid M 1 , the coalescent M 1 The structural expression of is: where the R 11 Indicates -CH 2 -, R 21 Indicates -CH 2 CH 2 CH 3 ;

[0077] The film-forming aid M 1 The reaction raw materials are: (A 1 , where the R 31 Indicates -CH 2 -), (B 1 , where the R 41 Indicates -CH 2 CH 2 CH 3 ), boron trifluoride, catalyst II; said A 1 , B 1 The molar ratio of the boron trifluoride is 1:1; the quality of the boron trifluoride is A 1 , B 1 0.1wt% of the total mass; the catalyst II is a mixture of sodium methylate and tetrapropylammonium bromide; the mass ratio of the sodium methylate and tetrapropylammonium bromide is 1:1; the quality of the sodium methylate is A 1 , B 1 0.6 wt% of the total mass.

[0078] The preparation method of described film-forming aid, comprises the steps:

[0079] (1) put A 1 , B 1 React with boron trifluoride at 90°C for 4h;

[0080] (2) Add catalyst II again and react at 120°C ...

Embodiment 2

[0082] Embodiment 2 provides a kind of film-forming aid M 2, the coalescent M 2 The structural expression of is: where the R 12 Indicates -CH 2 CH 2 -, R 22 Indicates -CH 2 CH 2 CH 2 CH 3 ;

[0083] The film-forming aid M 2 The reaction raw materials are: (A 2 , where the R 32 Indicates -CH 2 CH 2 -), (B 2 , where the R 42 Indicates -CH 2 CH 2 CH 2 CH 3 ), boron trifluoride, catalyst II; said A 2 , B 2 The molar ratio of the boron trifluoride is 1:1; the quality of the boron trifluoride is A 2 , B 2 0.1wt% of the total mass; the catalyst II is a mixture of sodium ethylate and tetrabutylammonium bromide; the mass ratio of sodium ethylate and tetrabutylammonium bromide is 1:1; the quality of the sodium ethylate is A 2 , B 2 0.6 wt% of the total mass.

[0084] The preparation method of described film-forming aid, comprises the steps:

[0085] (1) put A 2 , B 2 React with boron trifluoride at 90°C for 4h;

[0086] (2) Add catalyst II again and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com