Process for processing yellow tea

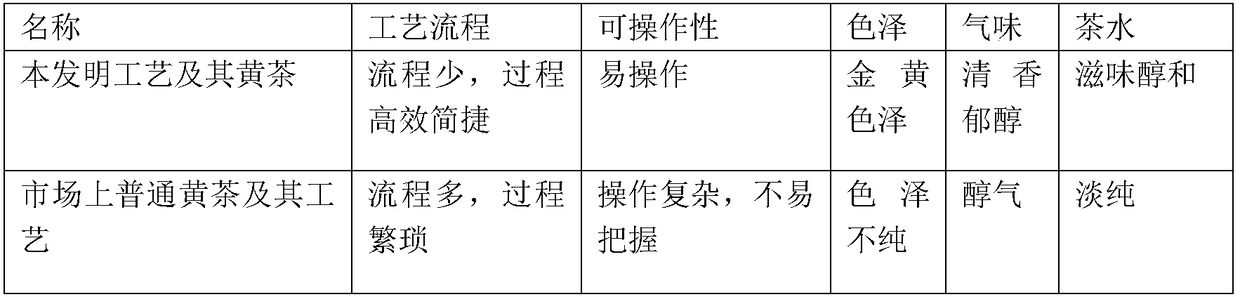

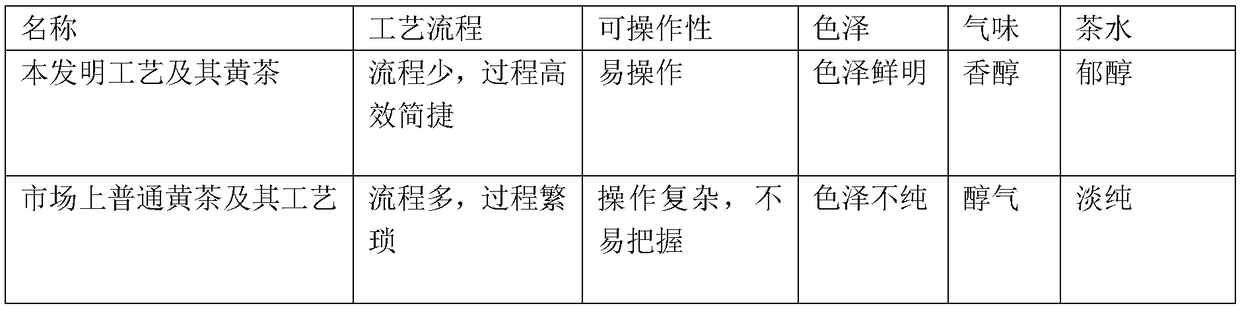

A processing technology and tea processing technology, which is applied in tea processing before extraction, etc., can solve the problems of multiple process operations, high process energy consumption, and different quality, and achieve efficient and simple process, low process energy consumption, and mellow taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

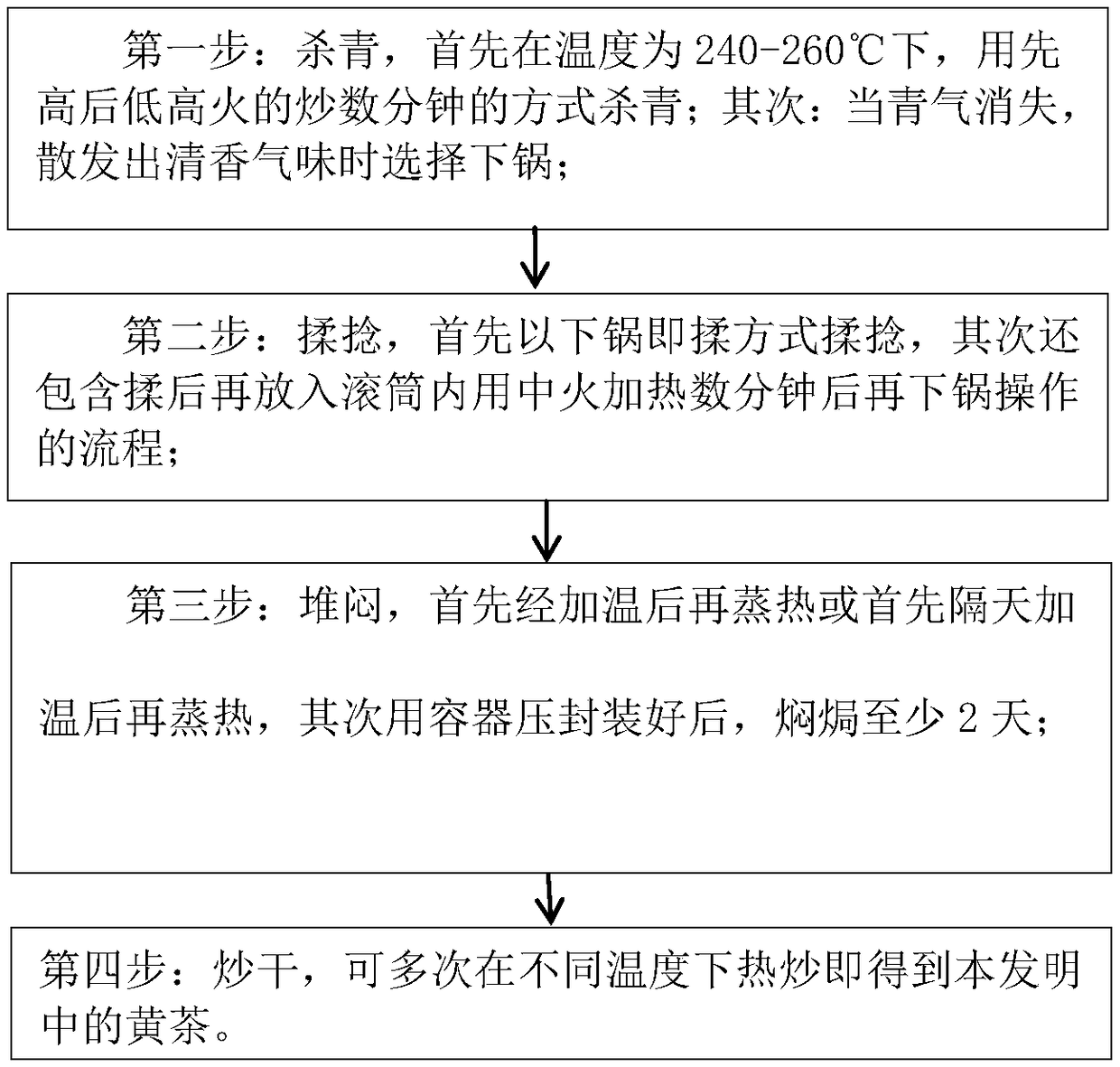

[0016] Example 1, as figure 1 As mentioned above, the present invention provides a yellow tea processing technology, which includes the following steps: the first step: killing greens, first at a high fire temperature of 250 ° C, frying greens in a manner of first high and then low and high fire for several minutes; secondly: when When the green gas disappears, choose to put it into the pot when sending out a delicate fragrance; preferably, the few minutes are 5 to 6 minutes;

[0017] The second step: kneading, first kneading in the way of kneading in the pot, and secondly including kneading and then putting it into the drum and heating it with medium heat for a few minutes before putting it in the pot; preferably, the heating in the second step is for a few minutes It is 4 to 6 minutes, and the process of kneading and kneading is also included after the pot is put into the pot again;

[0018] The third step: stacking stuffy, through the action of heat and humidity, the ingre...

Embodiment 2

[0022] Example 2, such as figure 1 As mentioned above, the present invention provides a yellow tea processing technology, which includes the following steps: the first step: killing greens, first at a high fire temperature within 260 ° C, frying greens in a way of first high and then low and high fire for several minutes; secondly: when When the green gas disappears, choose to put it into the pot when sending out a delicate fragrance; preferably, the several minutes are 6 minutes;

[0023] The second step: kneading, first kneading in the way of kneading in the pot, and secondly including kneading and then putting it into the drum and heating it with medium heat for a few minutes before putting it in the pot; preferably, the heating in the second step is for a few minutes It was 6 minutes, and the process of kneading and kneading was also included after the described potting again;

[0024] The third step: stacking stuffy, through the action of heat and humidity, the ingredien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com