A kind of preparation method of alicyclic polycarbonate

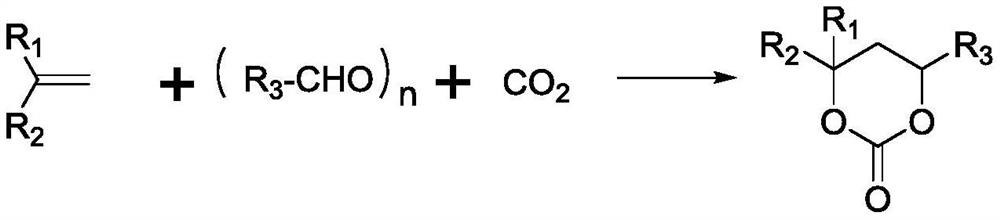

A technology for cyclic carbonate and aliphatic aldehyde, which is applied in the field of catalytic synthesis of chemical industry, can solve the problems of difficulty in obtaining and high price, and achieves the effects of cheap and easy-to-obtain process raw materials, simple operation, and efficient and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

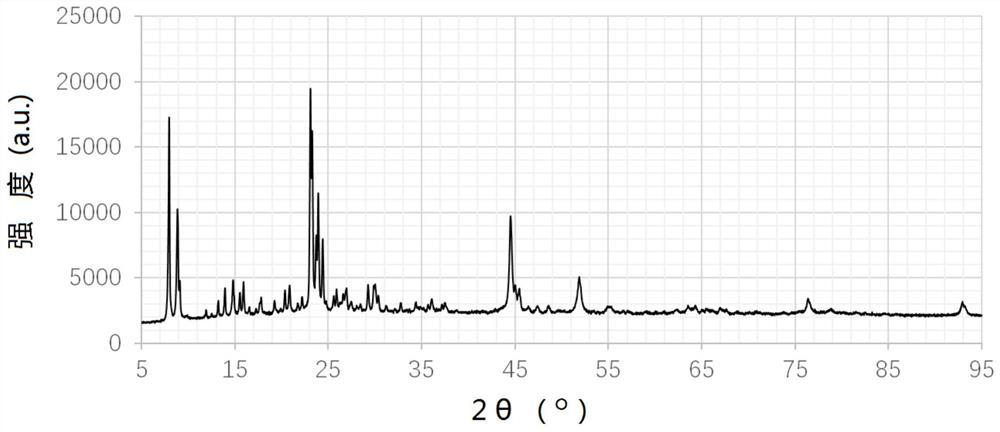

[0055] The preparation method of the catalyst according to the preparation method of aliphatic cyclic polycarbonate of the present invention can be carried out as follows: hydrogen-type molecular sieves such as H-β, SBA-15, H-Y, ZSM-5 (silicon-aluminum ratio 12-300), composite Oxide superacids such as SiO 2 -Al 2 O 3 , SiO 2 -TiO 2 , SiO 2 -ZrO 2 , SiO 2 -WO 3 , SiO 2 -MoO 3 , SiO 2 -SnO 2 , TiO 2 -ZrO 2 , TiO 2 -WO 3 , TiO 2 -Al 2 O 3 Vacuum dry to constant weight at 200°C, then drop to room temperature, add silica sol with a concentration of 20%-40% to the above carrier powder, and then add Ni, Pd, Rh, Ru, Sn, Cu, Co in an inert atmosphere , metal salts of Mn, Fe, Cr, or halide salts of transition metals such as porphyrin, bis(butanedione oxime, bisacetylacetone, Salen, etc. and Ni, Pd, Rh, Ru, Sn, Cu, Co, Mn, Fe, etc.) The formed complex precursor is hydrothermally or alcoholic heat-treated at 40-95°C for 2-48h, and the solid obtained by suction filtratio...

Embodiment 1

[0064] The H-ZSM-5 (Si / Al=38) was dewatered and degassed under vacuum at 200°C for 6h, then put into a flask, and the required amount of toluene solution of 3-aminopropyltriethoxysilane was added under nitrogen protection. added, and stirred at room temperature for 24 h, evaporated the solvent, and vacuum-dried at 150 °C to obtain a carrier precursor modified with surface ammonia. The amino group in the prepared precursor accounted for the SiO in ZSM-5. 2 The quality fraction of 20%. The synthesis of Co-Salen was carried out according to the reported route (L.E.Martínez, J.L.Leighton, D.H.Carsten, E.N.Jacobsen, J.Am.Chem.Soc.117(1997) 5897.), the Salen ligand was via tert-butylsalicylic Aldehyde and ethylenediamine structure amines through the condensed Schiff base. Add 20 g of carrier precursor to the flask, under N 2 Dichloromethane was added under the protection, fully stirred to form a suspension, 50 g of Co-Salen solution in dichloromethane was added, stirred at room te...

Embodiment 2

[0066] The SBA-15 was dewatered and degassed under vacuum at 200°C for 6h, then put into a flask, and the required amount of toluene solution of 3-aminopropyltriethoxysilane was added under nitrogen protection, and stirred at room temperature for 24h, Evaporate the solvent to dryness and vacuum dry at 150°C to obtain a carrier precursor modified with surface ammonia. The amino group in the prepared precursor is the same as the SiO in SBA-15. 2 The mass ratio is 1:5. The synthesis of Co-Salen was carried out according to the reported route (L.E.Martínez, J.L.Leighton, D.H.Carsten, E.N.Jacobsen, J.Am.Chem.Soc.117(1997) 5897.), the Salen ligand was via tert-butyl water The amines of sylaldehyde and ethylenediamine structure pass through the condensed Schiff base. Add 20 g of carrier precursor to the flask, under N 2 Dichloromethane was added under the protection, fully stirred to form a suspension, 50 g of Co-Salen solution in dichloromethane was added, stirred at room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com