Propane dehydrogenated propylene preparation dehydration reactor

A dehydrogenation reactor and propane dehydrogenation technology, which is applied in the field of propane, can solve problems such as affecting subsequent use, unstable hoisting, and easy entry of foreign objects into the opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

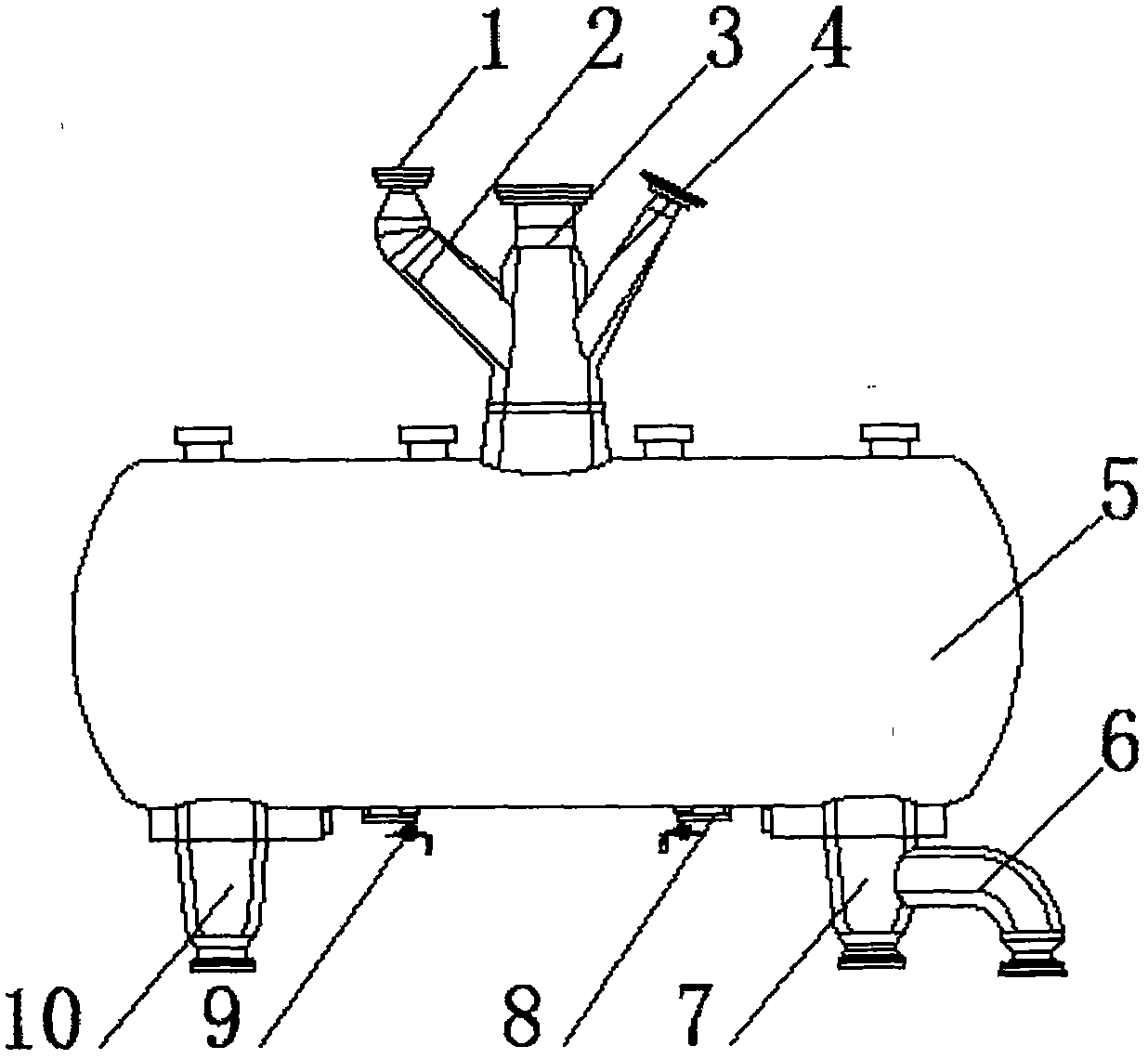

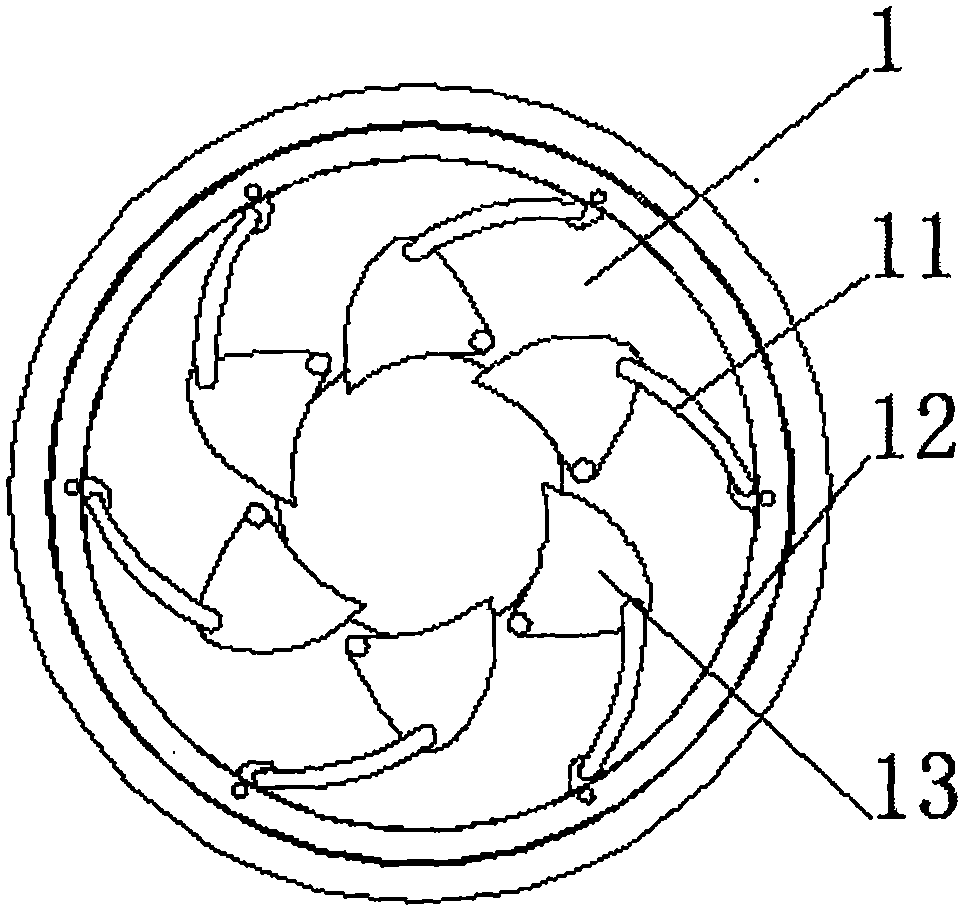

[0019] see figure 1 , figure 2 with image 3 , the present invention provides a technical solution: a dehydrogenation reactor for propane dehydrogenation to propylene, including a reactor mechanism, a limit mechanism and a protective cover A1, the inner wall of the protective cover A1 is provided with a protective cover B12, and the protective cover B12 It is fixedly connected with the reactor mechanism through a groove, the inner wall of the protective cover B12 is connected with the mask connecting rod 11 through the rotating shaft, the lower surface of the protective cover A1 is connected with the protective mask 13 through the rotating shaft, and the mask connecting rod 11 It is rotatably connected with the protection mask 13 through a rotating shaft.

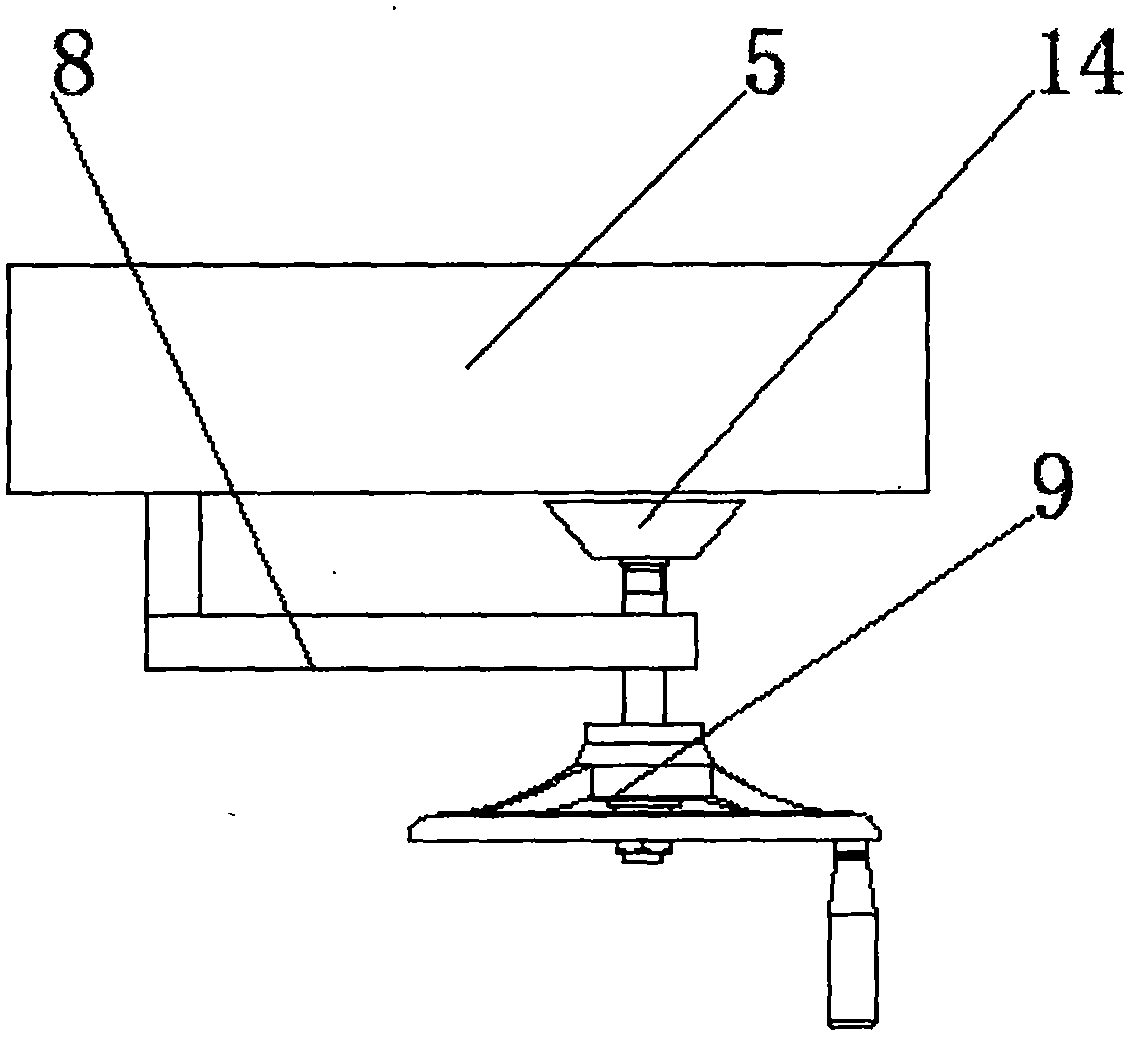

[0020] For ease of use, in this embodiment, preferably, the reactor mechanism includes a hydrocarbon inlet 2, an air inlet 3, a reducing gas inlet 4, a reactor outer cylinder 5, a hydrocarbon outlet 10, an air outlet 7 a...

Embodiment 2

[0025] see figure 1 , figure 2 with image 3 , the present invention provides a technical solution: a dehydrogenation reactor for propane dehydrogenation to propylene, including a reactor mechanism, a limit mechanism and a protective cover A1, the inner wall of the protective cover A1 is provided with a protective cover B12, and the protective cover B12 It is fixedly connected with the reactor mechanism through a groove, the inner wall of the protective cover B12 is connected with the mask connecting rod 11 through the rotating shaft, the lower surface of the protective cover A1 is connected with the protective mask 13 through the rotating shaft, and the mask connecting rod 11 It is rotatably connected with the protection mask 13 through a rotating shaft.

[0026] For ease of use, in this embodiment, preferably, the reactor mechanism includes a hydrocarbon inlet 2, an air inlet 3, a reducing gas inlet 4, a reactor outer cylinder 5, a hydrocarbon outlet 10, an air outlet 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com