Highly oriented cellulose aerogel and preparation method thereof

A technology of cellulose aerogel and cellulose hydrogel, which is applied in the field of highly oriented cellulose aerogel and its preparation, can solve the problems of inability to prepare cellulose aerogel, and achieve easy large-scale industrial production. , the effect of improving the preparation efficiency and reducing the replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

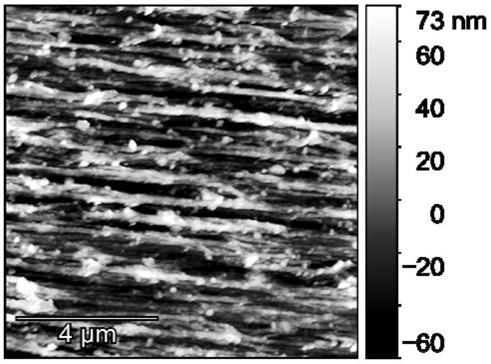

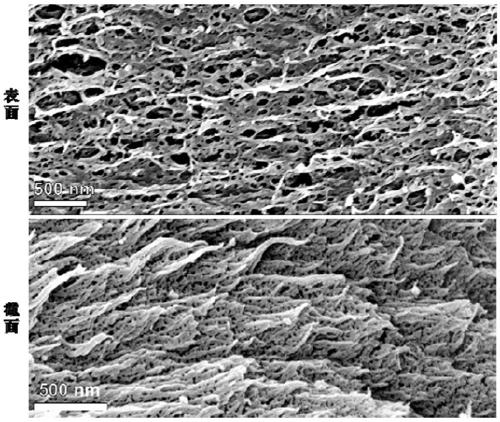

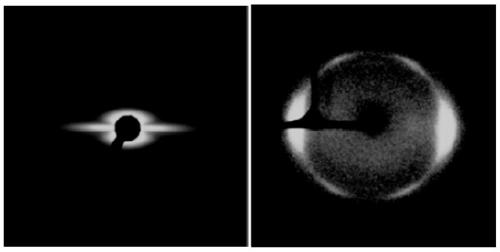

Image

Examples

preparation example Construction

[0031] According to a first aspect of the present invention, the present invention provides a method for preparing a highly oriented cellulose airgel, comprising the following steps:

[0032] (a) adding a chemical crosslinking agent to the cellulose solution for chemical crosslinking to obtain a chemically crosslinked cellulose hydrogel;

[0033] (b) performing pre-stretching and alcohol solution replacement on the chemically cross-linked cellulose hydrogel, and drying to obtain a highly oriented cellulose airgel material.

[0034] The preparation method of the highly oriented cellulose airgel provided by the present invention is simple in operation, low in cost, and easy for large-scale industrial production. Alcohol coagulation bath is used to freeze the orientation, and at the same time, the hydrogel is replaced with alcohol gel, and the orientation of the hydrogel is fixed. Carried out together with solvent replacement, the replacement time and the amount of alcohol are gr...

Embodiment 1

[0090] This embodiment provides a highly oriented cellulose airgel, the preparation method of which comprises the following steps:

[0091] (a) Control the experimental temperature to be lower than the cellulose gelation temperature, add epichlorohydrin to the cellulose solution with a mass fraction of 4wt%, wherein the mass ratio of epichlorohydrin to cellulose is 3.55:4, and stir rapidly 3h, centrifugal defoaming, standing at 0°C for 6h to obtain chemically cross-linked cellulose hydrogel;

[0092] (b) Pre-stretching the chemically cross-linked cellulose hydrogel obtained in step (a), wherein the deformation of the pre-stretching is 200%, and then placing the cellulose hydrogel in a 95% mass fraction In the ethanol solution, the ethanol solution was replaced every 3 hours at -5°C. After three replacements, the above-mentioned alcohol gel was placed in a supercritical dryer for supercritical drying to obtain a highly oriented cellulose airgel material.

Embodiment 2

[0094] This example provides a highly oriented cellulose airgel. The difference between the preparation method of this example and Example 1 is that the pre-stretching deformation is 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com