A kind of deep sea buoyancy material and preparation method thereof

A buoyant material and deep-sea technology, applied in the field of chemical materials, can solve the problems of restricting the performance of deep-sea buoyancy materials, easy breakage of hollow glass microspheres, and increasing the density of hollow glass microspheres. The effect of improving the uniform dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

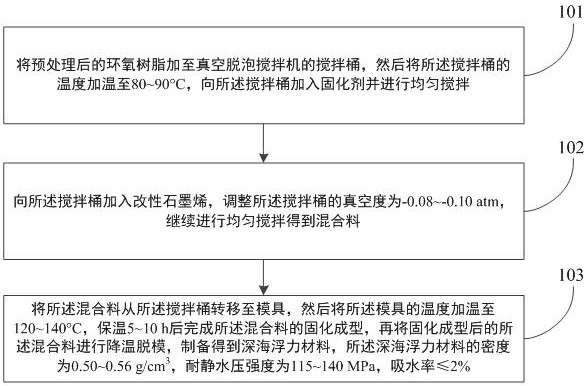

[0031] figure 1 It is a method flowchart of a method for preparing a deep-sea buoyant material shown according to an exemplary embodiment, such as figure 1 As shown, the method includes:

[0032] Step 101: Add the pretreated epoxy resin to the mixing tank of the vacuum defoaming mixer, then heat the temperature of the mixing tank to 80-90°C, add a curing agent to the mixing tank and stir evenly .

[0033] In a possible implementation, the pretreatment method of the epoxy resin includes:

[0034] Epoxy resin is heated up to 85 ~ 95 DEG C, when described epoxy resin is in complete molten state, add epoxy reactive diluent, after stirring evenly at 85 ~ 95 DEG C for 10 ~ 20 min, cool down to 55 ~ 65 ° C, the pretreated epoxy resin is prepared, and the mass and number ratio of the epoxy resin to the epoxy reactive diluent is 100:15 ~ 25.

[0035] Wherein, the epoxy resin contains three or four epoxy groups, and the epoxy reactive diluent contains two epoxy groups. For example,...

Embodiment 1

[0052] (1) Preparation of modified graphene:

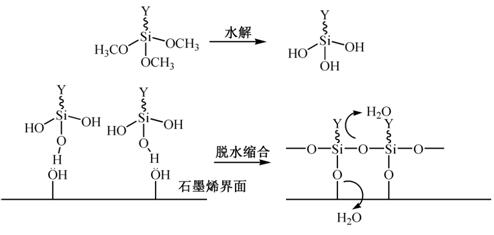

[0053] Calculated by mass parts, the density is 0.04 g / cm 3 5 parts of graphene were added to 300 parts of absolute ethanol for ultrasonic dispersion for 60 min to prepare a graphene solution; 200 parts of absolute ethanol and 40 parts of deionized water were mixed to form a mixed solution, and acetic acid was added to the mixed solution to adjust The pH value of the mixed solution is 3.5~4.5, then slowly add 0.5 parts of silane coupling agent dropwise to the mixed solution, stir and disperse the mixed solution at high speed for 60 min, and prepare the silane coupling agent solution; The graphene solution was slowly added to the silane coupling agent solution to form a reaction solution, and the reaction solution was controlled to react at a reaction temperature of 80° C. for 6 h, and the reaction solution was suction-filtered and dried to prepare modified graphene.

[0054] (2) Pretreatment of epoxy resin:

[0055] Calculated i...

Embodiment 2

[0059] (1) Preparation of modified graphene:

[0060] Calculated by mass parts, the density is 0.03 g / cm 3 Add 4 parts of graphene to 300 parts of absolute ethanol and ultrasonically disperse for 90 min to prepare a graphene solution; 200 parts of absolute ethanol and 40 parts of deionized water are mixed to form a mixed solution, and acetic acid is added to the mixed solution to adjust The pH value of the mixed solution is 3.5 ~ 4.5, then slowly drop 0.8 parts of silane coupling agent to the mixed solution, stir and disperse the mixed solution at high speed for 60 min, and prepare the silane coupling agent solution; The graphene solution was slowly added to the silane coupling agent solution to form a reaction solution, and the reaction solution was controlled to react at a reaction temperature of 80° C. for 7 h, and the reaction solution was suction-filtered and dried to prepare modified graphene.

[0061] (2) Pretreatment of epoxy resin:

[0062] Calculated in parts by ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com