Short-process printing and dyeing method of superfine denier polyester fiber

A polyester fiber, short process technology, applied in the field of printing and dyeing, can solve problems such as the inability to meet actual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

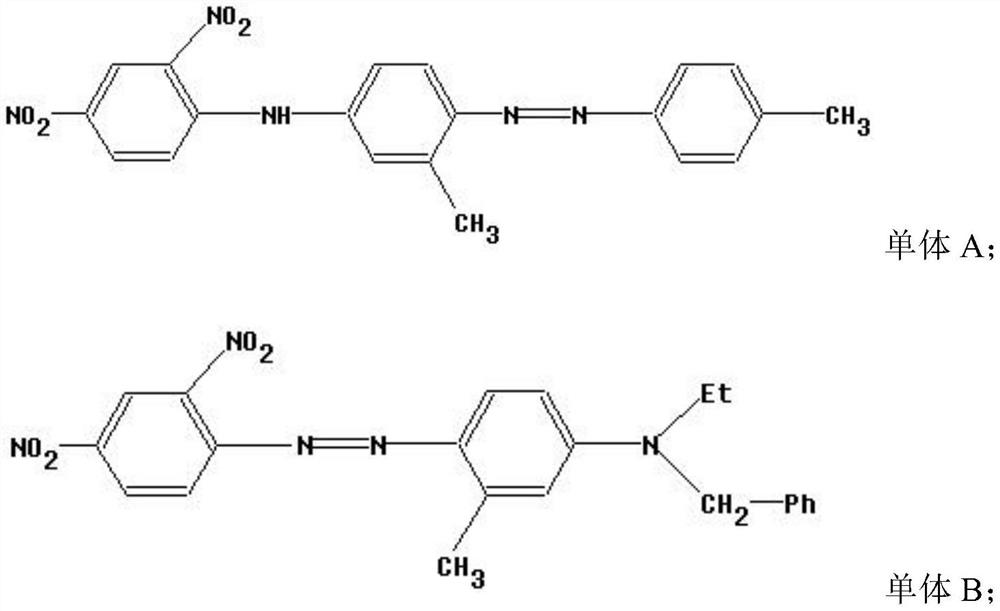

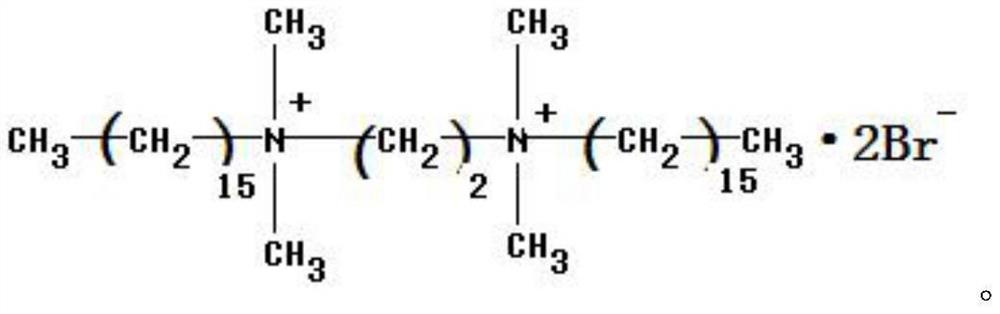

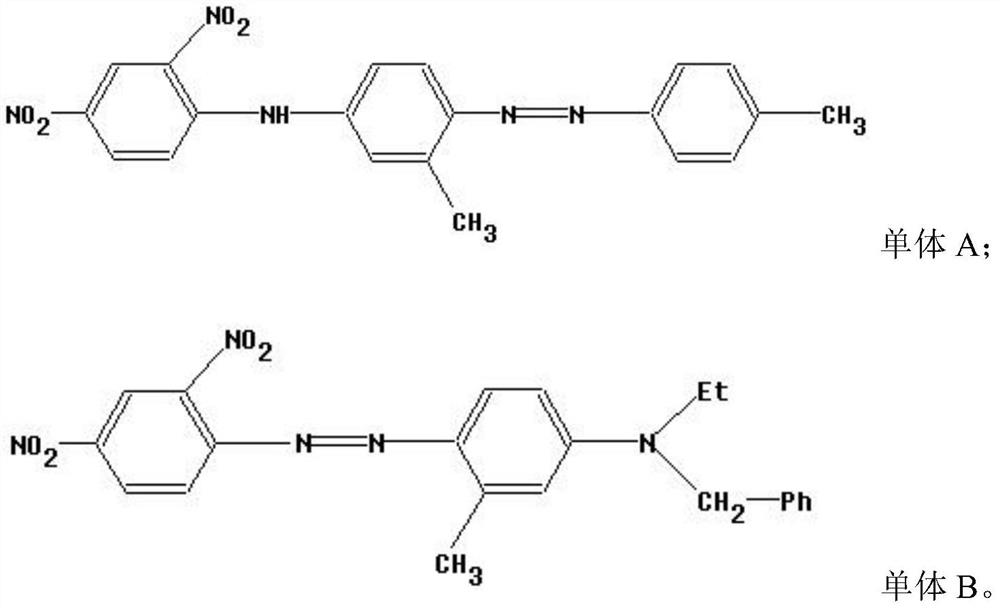

Method used

Image

Examples

Embodiment 1

[0062] At room temperature of 25°C, put 240T pongee superfine polyester fabric into the alkaline dyeing bath; heat up to 105°C, the heating process is fast and then slow, divided into two stages: the first stage, room temperature to 80 °C, the heating rate is 2.5 °C / min; in the second stage, 80 °C to the target temperature, the heating rate is 1 °C / min; and then keep at the target temperature for 50 min. Then the temperature was lowered to 80°C, and washed twice with water, 10 min each time. Then carry out the reduction cleaning step, the conditions are: sodium hydroxide 2.5g / L, hydrosulfite 2.5g / L, temperature 65°C, bath ratio 1:45, and time 20min. Then wash with water again 5 times, each time for 10 minutes; finally dry. Wherein, the formula of described alkaline dyeing bath is as follows:

[0063] Sodium hydroxide 3g / L;

[0064] Benzyl alcohol 15g / L;

[0065] Disperse yellow dye 3o.w.f%;

[0066] Dispersant MF 1g / L;

[0067] Quaternary ammonium salt accelerator 0.08g / ...

Embodiment 2

[0073] At room temperature of 25°C, put 240T pongee superfine polyester fiber fabric into the alkaline dyeing bath; heat up to 106°C, the heating process is first fast and then slow, divided into two stages: the first stage, room temperature to 80 ℃, the heating rate is 2°C / min; in the second stage, from 80°C to the target temperature, the heating rate is 0.5°C / min; then keep at the target temperature for 60 minutes. Then cool down to 80°C and wash with water 4 times, 10 min each time. Then carry out the reduction cleaning step, the conditions are: sodium hydroxide 3g / L, hydrosulfite 3g / L, temperature 65°C, bath ratio 1:45, and time 20min. Then wash again 8 times, 10min each time; finally dry. Wherein, the formula of described alkaline dyeing bath is as follows:

[0074] Sodium hydroxide 4g / L;

[0075] Benzyl alcohol 12g / L;

[0076] Disperse yellow dye 4o.w.f%;

[0077] Dispersant MF 1.2g / L;

[0078] Quaternary ammonium salt accelerator 0.10g / L.

[0079] Wherein, descri...

Embodiment 3

[0084] At room temperature of 25°C, put 240T pongee superfine polyester fiber fabric into the alkaline dyeing bath; heat up to 104°C, the heating process is fast and then slow, divided into two stages: the first stage, room temperature to 80 ℃, the heating rate is 3°C / min; in the second stage, from 80°C to the target temperature, the heating rate is 1°C / min; then keep at the target temperature for 40min. Then the temperature was lowered to 80°C, and washed twice with water, 10 min each time. Then carry out the reduction cleaning step, the conditions are: sodium hydroxide 2g / L, sodium hydroxide 2g / L, temperature 60°C, bath ratio 1:40, and time 20min. Then wash 6 times with water again, 10min each time; finally dry. Wherein, the formula of described alkaline dyeing bath is as follows:

[0085] Sodium hydroxide 2g / L;

[0086] Benzyl alcohol 12g / L;

[0087] Disperse yellow dye 2o.w.f%;

[0088] Dispersant MF 0.5g / L;

[0089] Quaternary ammonium salt accelerator 0.02g / L.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com