Efficient, short-flow and less-water textile printing and dyeing equipment

A textile printing and dyeing, short-process technology, which is applied in the field of high-efficiency short-process and low-water textile printing and dyeing equipment, can solve the problems of increased discharge and pollution level of printing and dyeing wastewater, complex composition of printing and dyeing wastewater, and poor wrinkle removal effect, so as to improve the printing and dyeing efficiency. Efficiency, improve service life, improve the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

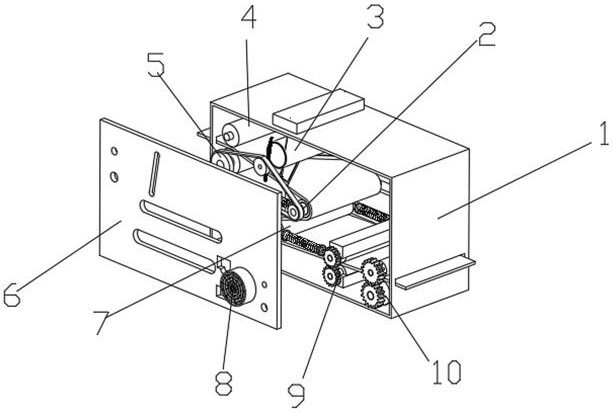

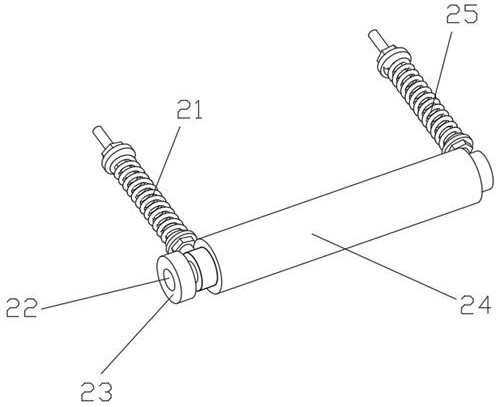

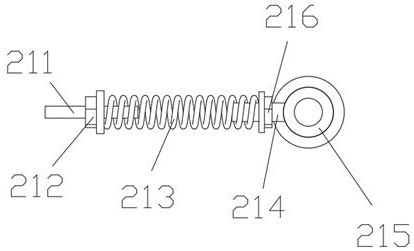

[0030] See Figure 1-7 As shown, a high-efficiency, short-flow, low-water textile printing and dyeing equipment includes an equipment housing 1, a first tensioning mechanism 2, a wrinkle removing mechanism 3, an input driving mechanism 4, a transmission mechanism 5, a side cover 6, and a second tensioning mechanism 7. , Air-drying mechanism 8, printing and dyeing mechanism 9 and output mechanism 10. The air-drying mechanism 8 is embedded in the side cover 6. The side cover 6 is fixed on one side of the equipment housing 1, and the input driving mechanism 4 is fixed inside the equipment housing 1 and is located in the equipment On the inner front end wall of the housing 1, the first tensioning mechanism 2 is slidably arranged inside the equipment housing 1, and the first tensioning mechanism 2 is located behind the input drive mechanism 4, and the wrinkle removing mechanism 3 is arranged inside the equipment housing 1 to remove wrinkles. The upper end of the mechanism 3 is embed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com