Installation method of flexible cables spanning string beams of existing buildings

A flexible cable and existing building technology, applied in construction, building maintenance, building construction, etc., can solve the problem of inappropriate installation method of the flexible cable for tensioned beams, reduce the difficulty of traction, improve the stability, and avoid friction damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

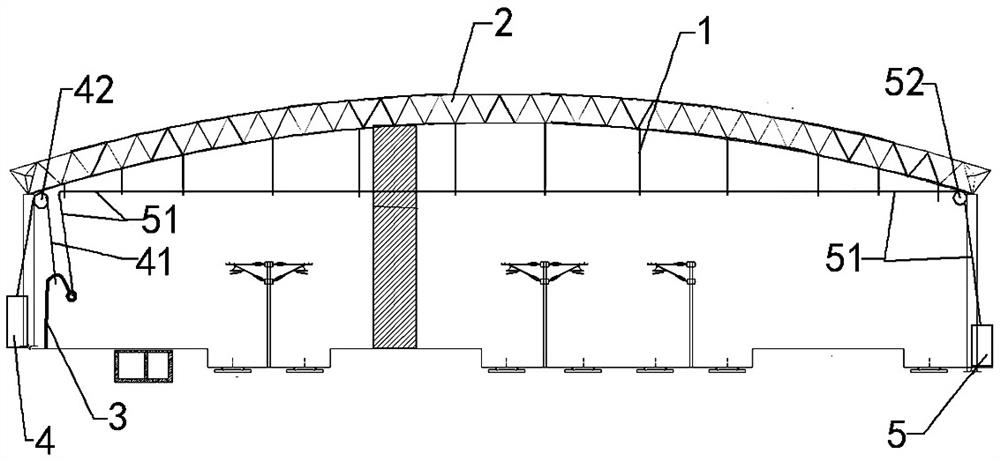

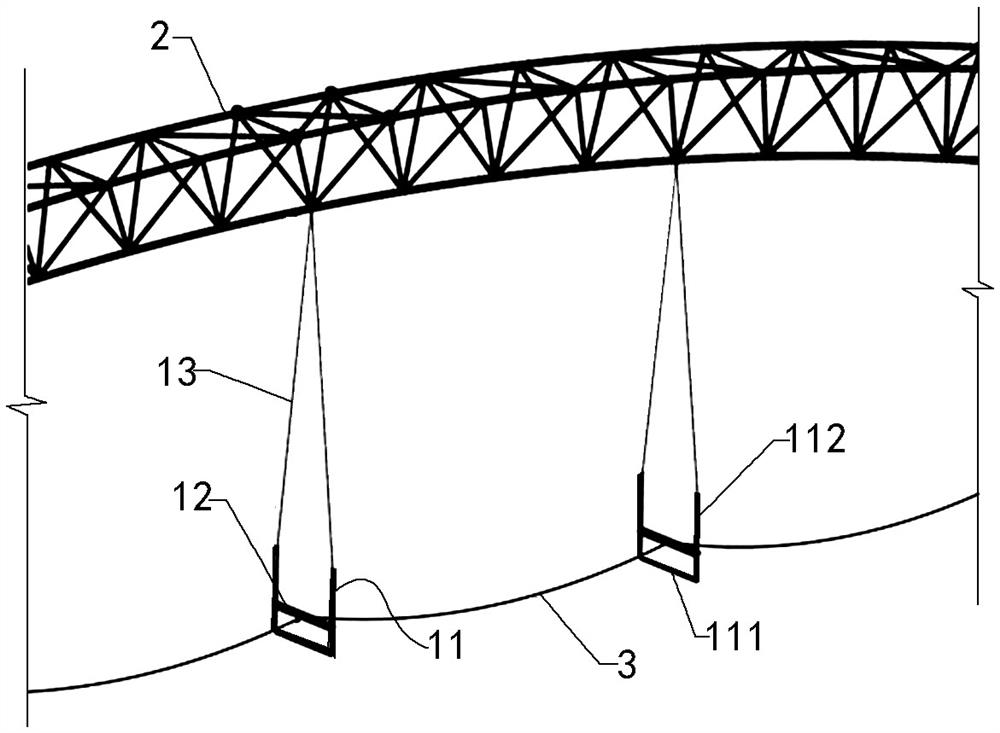

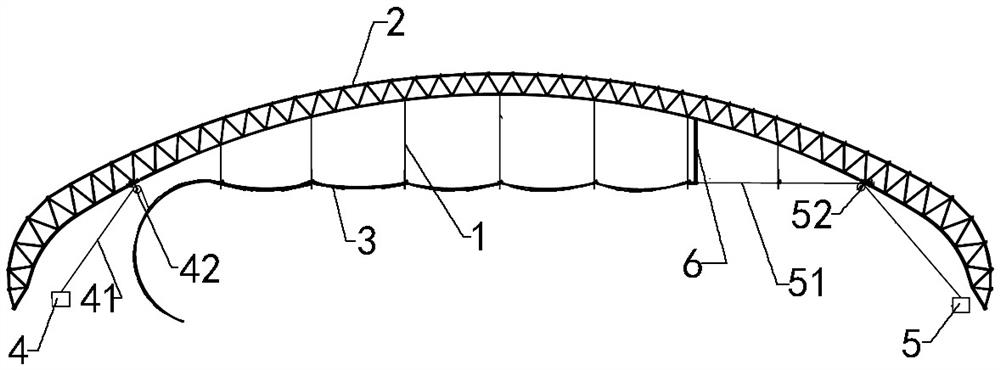

[0043] Such as Figure 1 to Figure 2 As shown, the installation structure of the string beam flexible stay cable spanning the existing buildings of the present invention includes a pulley slide device 1 suspended under the upper string girder 2, a hoist hoist 4 for vertically lifting the stay cable body 3, and a hoisting hoist 4 for horizontal The traction hoist 5 for pulling the cable body 3 and the cable body 3 passing through the pulley cable device 1 .

[0044] The pulley cable device 1 is arranged at intervals along the direction of the upper chord main beam 2. The pulley cable device 1 is as close as possible to the strut of the string beam. The distance between adjacent pulley cable devices 1 needs to be determined according to the calculated simulation model. The simulation model is based on The sag of the cable body 3 under its own weight is greater than the requirement of the safety distance of the existing building, and the construction process simulation model of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com