Large-flow oil pumping device with multiple radial plunger pistons

A multi-plunger pump, high-flow technology, which is applied to the components of the pumping device for elastic fluid, multi-cylinder pumps, pumps, etc. , The effect of uniform force and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the existing plunger pump, the pump oil volume of the plunger assembly is very small. When a hydraulic tool needs a large flow, the motor needs to increase the speed to increase the pump oil volume. The high-speed operation of the motor makes the heat generation very large and the increase in the flow is not ideal. In view of this, the present invention provides a large-flow radial multi-piston oil pump device.

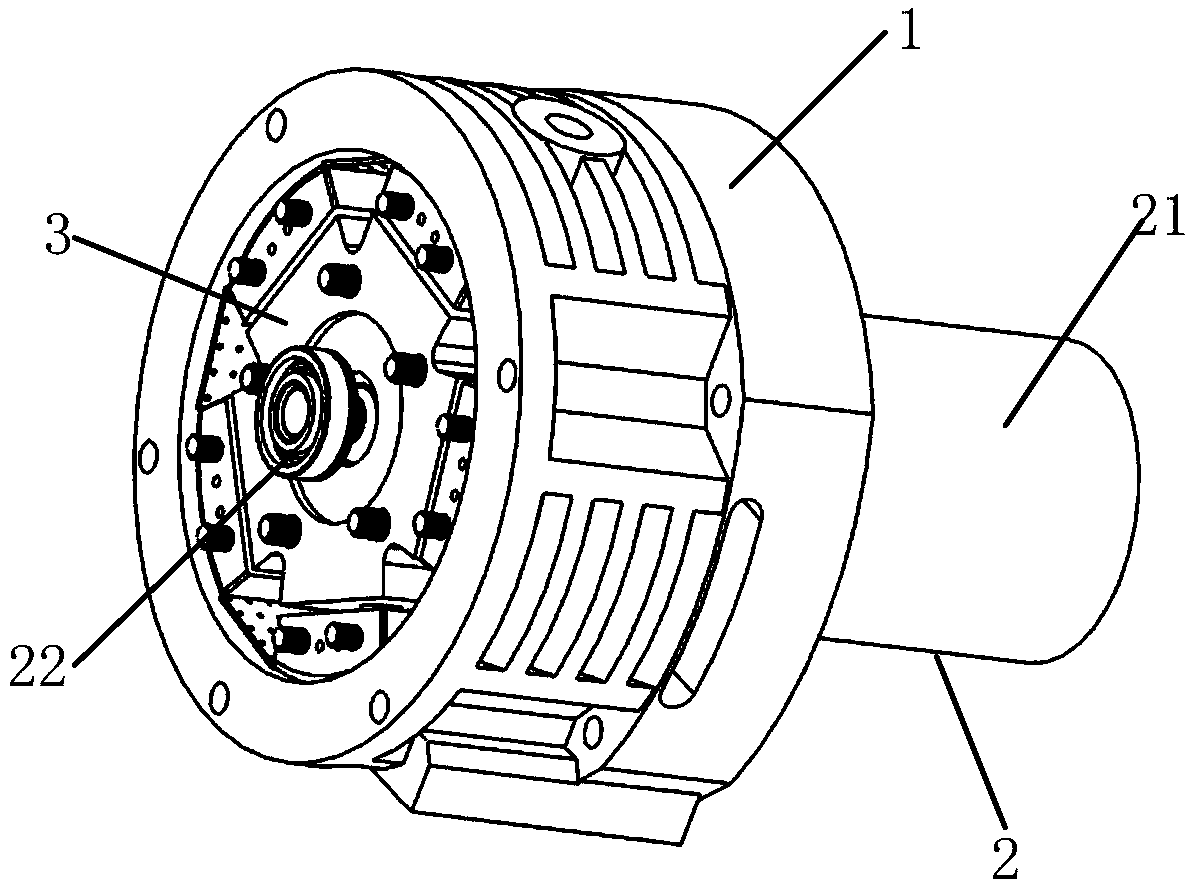

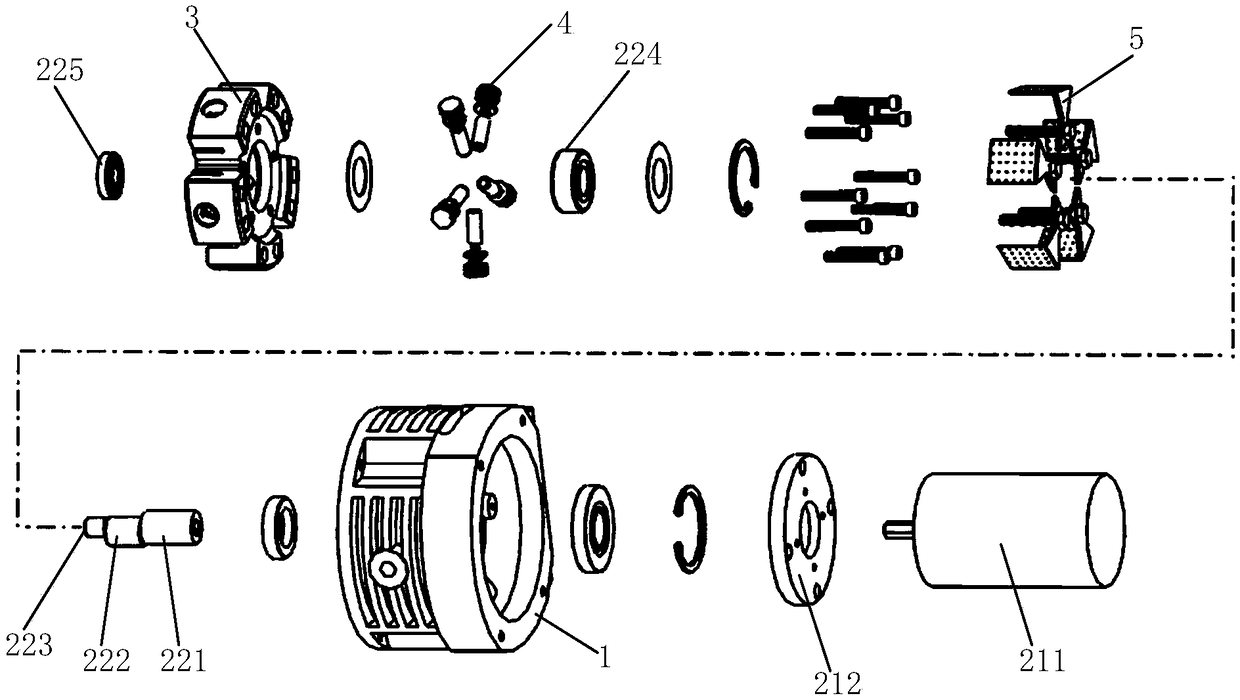

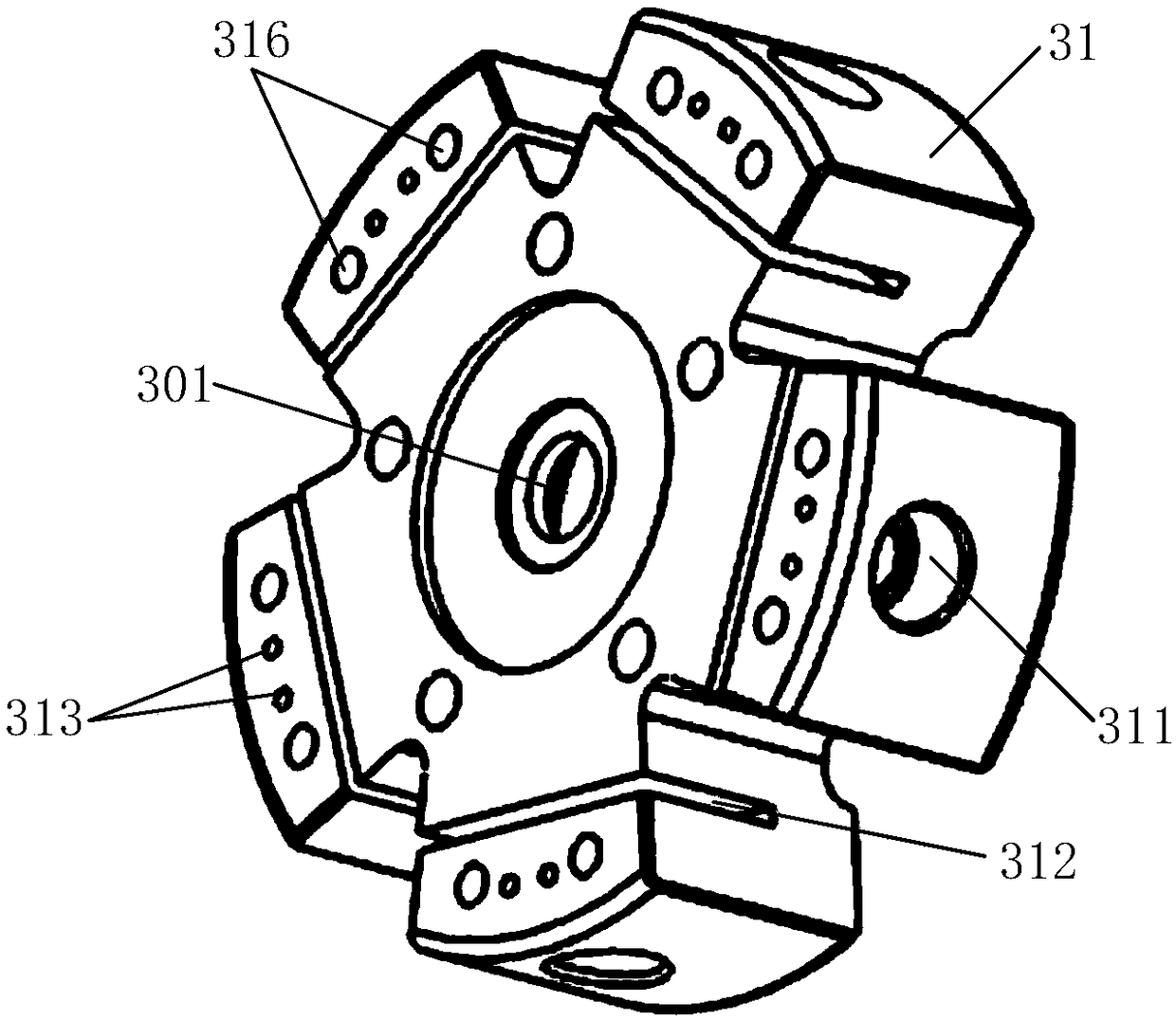

[0033] The large-flow radial multi-plunger pump oil device provided by this embodiment includes a housing 1, a drive assembly 2, a plunger valve body 3, at least five plunger assemblies 4, and a connecting part. The drive assembly 2 is fixed to the housing 1, and the drive assembly 2 includes a motor assembly 21 and an eccentric assembly 22. The plunger valve body 3 is arranged in the housing 1. The plunger valve body 3 has a mounting hole 301 in the middle, and the eccentric wheel assembly 22 extends into the mounting hole 301. The plunger valve body 3 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com