A sealing machine

A cover glass and slide glass technology, applied in the field of medical devices, can solve the problems of slow speed, easy generation of air bubbles, affecting specimen observation, etc., and achieve the effects of reducing production cost, preventing air bubbles, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

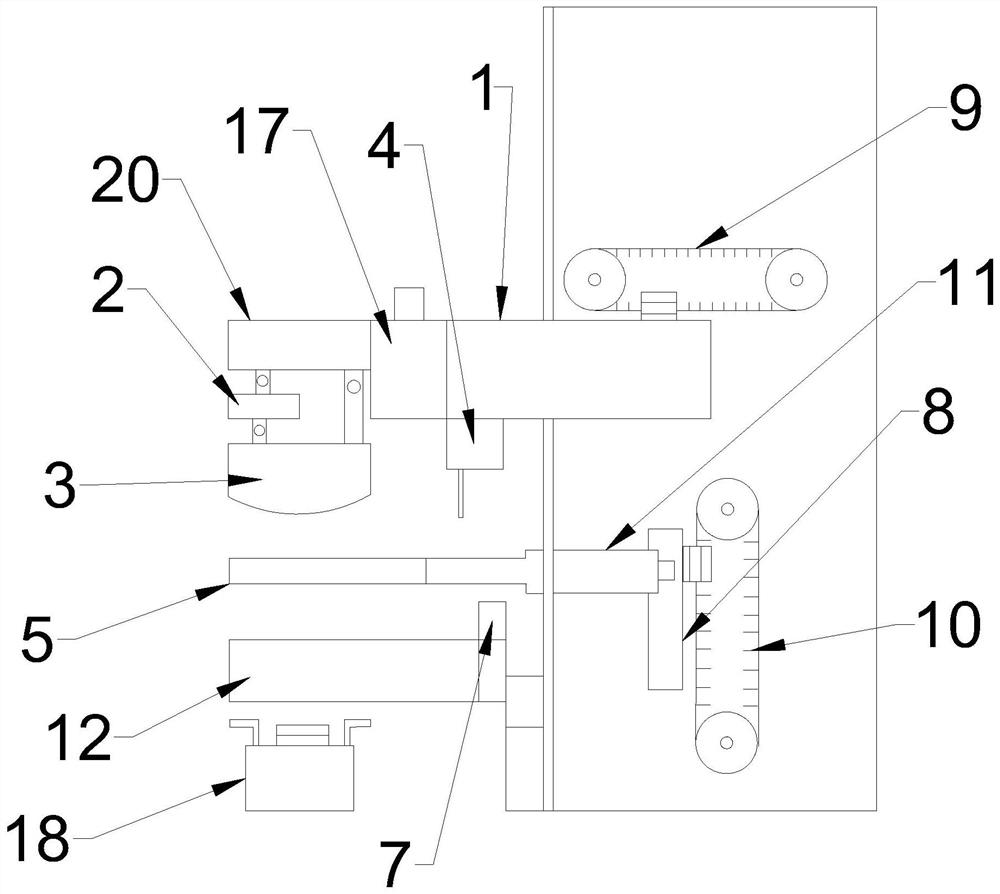

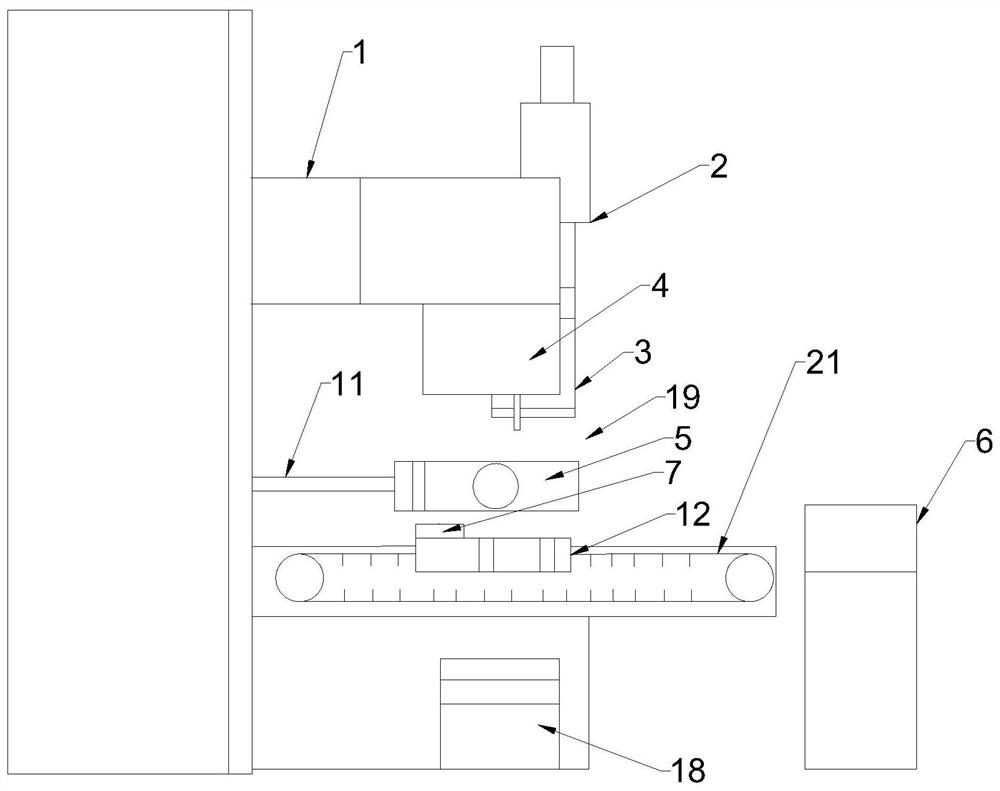

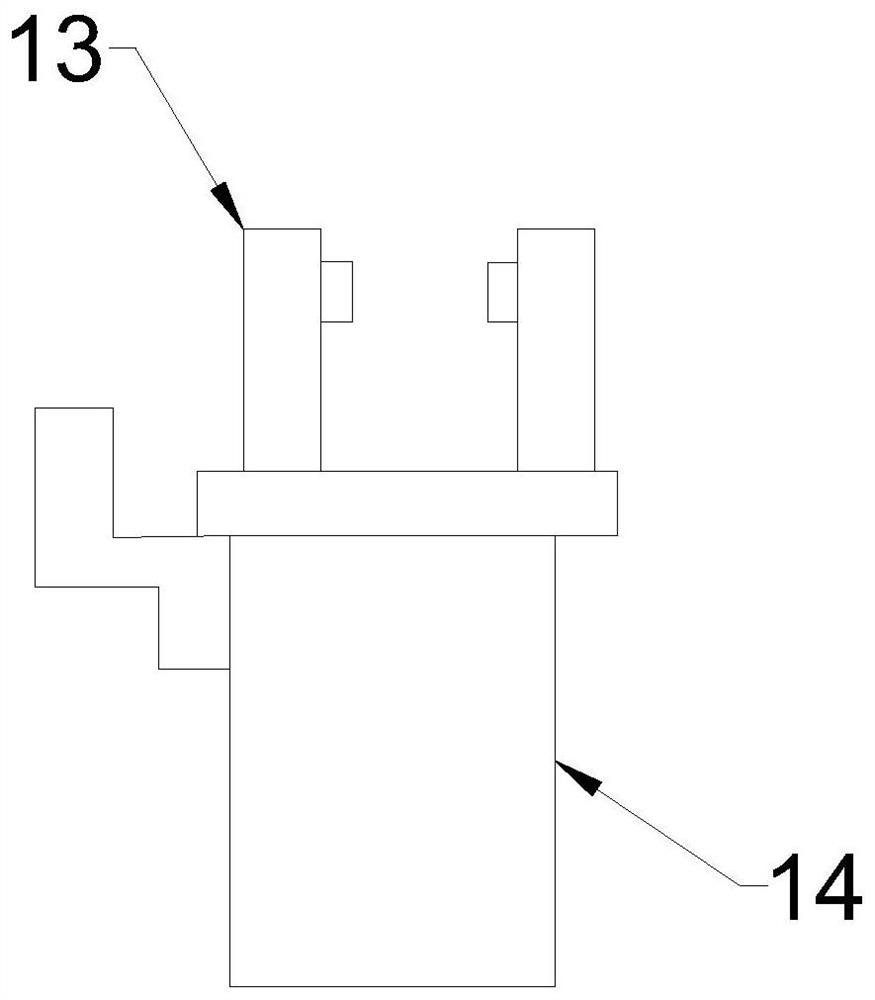

[0021] like Figure 1-5 As shown, it includes a coverslipper housing, and a suction head assembly arranged on the coverslipper housing for picking up a cover glass and affixing a cover on the slide glass, and a discharge material for assisting the cover and for conveying the material. The platform 12, the grab assembly for grabbing the slides, the slide cassette 18 for placing the slides, and the slide rack 6 for collecting the finished slides, the slide cassette 18 is arranged in the grabbing The suction head assembly includes a cover glass box 19 for placing the cover glass, a pressing block mechanism 3 for sucking the cover glass, and a pressure block mechanism for lifting and lowering the cover glass to pick up the cover glass. The suction head cylinder 17, the cover glass box 19 is placed directly under the pressure block mechanism 3, the suction head cylinder frame 20 is fixed on the output end of the suction head cylinder 17, and the suction head cylinder frame 20 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com