Quality inspection method of hydraulic structures based on BIM

A quality inspection and structure technology, applied in image data processing, instruments, 3D modeling, etc., can solve problems such as unreasonable waterproof structure, low efficiency and unreasonable query of structure leakage and seepage, and achieve the purpose of avoiding project operation risks, Improve the efficiency of comprehensive management and solve the effect of cumbersomeness and mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with accompanying drawing, and the principle of this method is very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

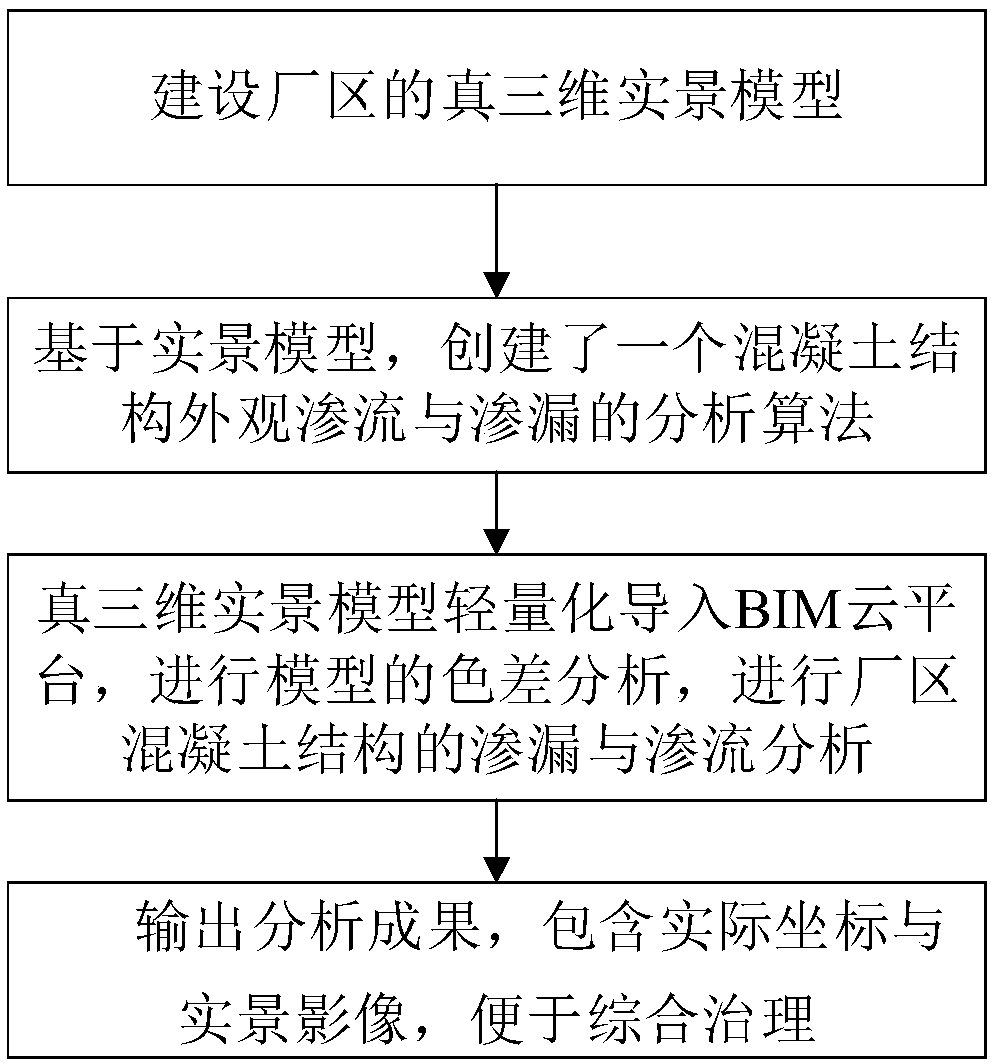

[0053] see figure 1 , in this embodiment, the general steps of the BIM-based quality inspection method for hydraulic structures are as follows:

[0054] Step 1: Based on the oblique photography technology of the UAV, a real three-dimensional real scene model of the factory area is established.

[0055] Step 2: Import the light-weight real 3D real scene model into the BIM cloud platform, analyze the color difference of the model, obtain the leakage and seepage analysis of the concrete structure in the factory area, and present the analysis results of leakage and seepage in the BIM cloud service data analysis platform.

[0056] Step 3: Output the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com