Parallel rope drive antenna base mechanism

A technology of rope drive and antenna seat, which is applied in the field of parallel rope drive antenna seat mechanism, can solve problems such as the inability to ensure accurate tracking of the antenna reflection surface, insufficient processing accuracy and installation error, and application limitations of the rope drive mechanism, etc., achieving low cost and lightening The overall weight and the effect of simplifying the structure of the antenna base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Exemplary embodiments, features, and performance aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

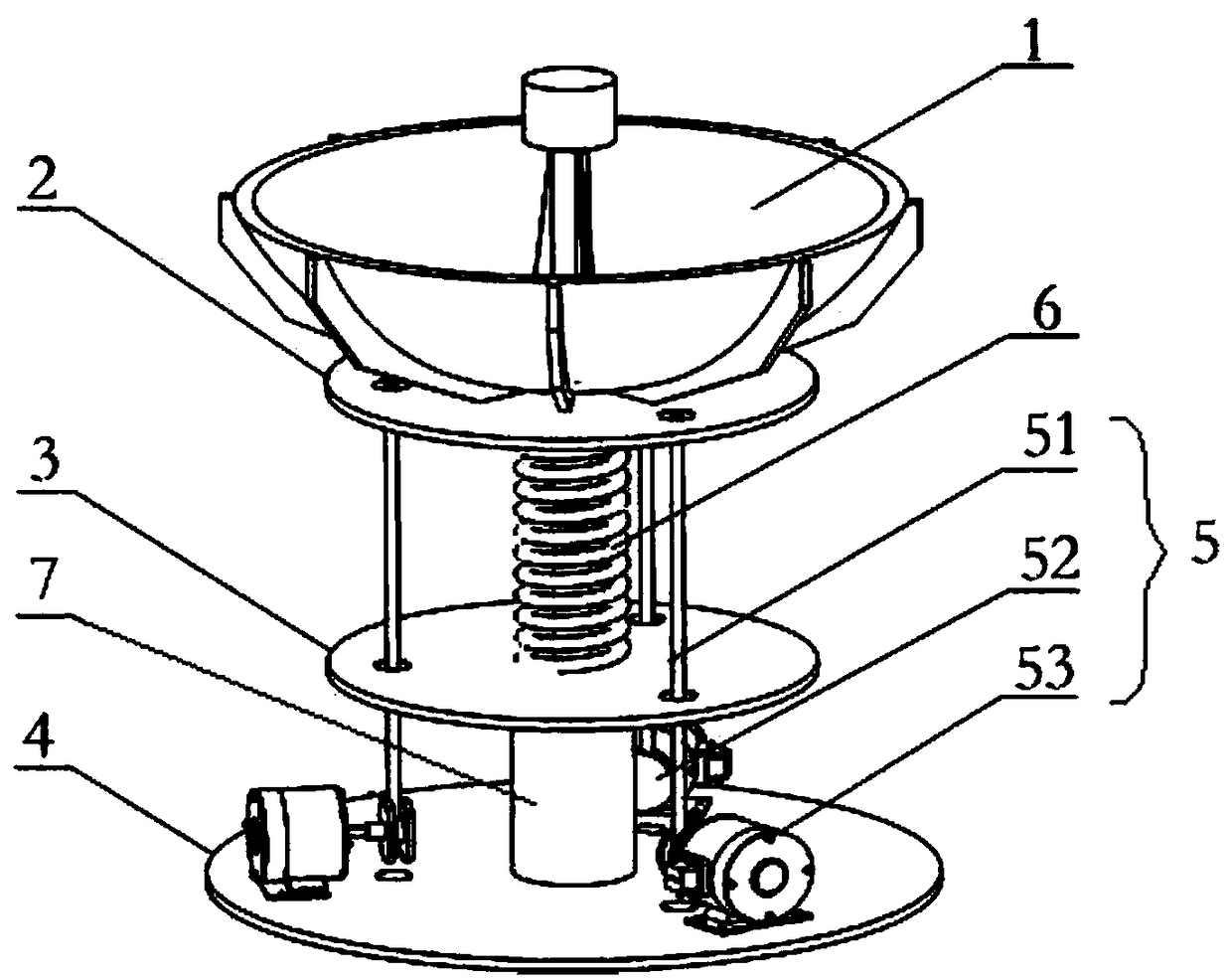

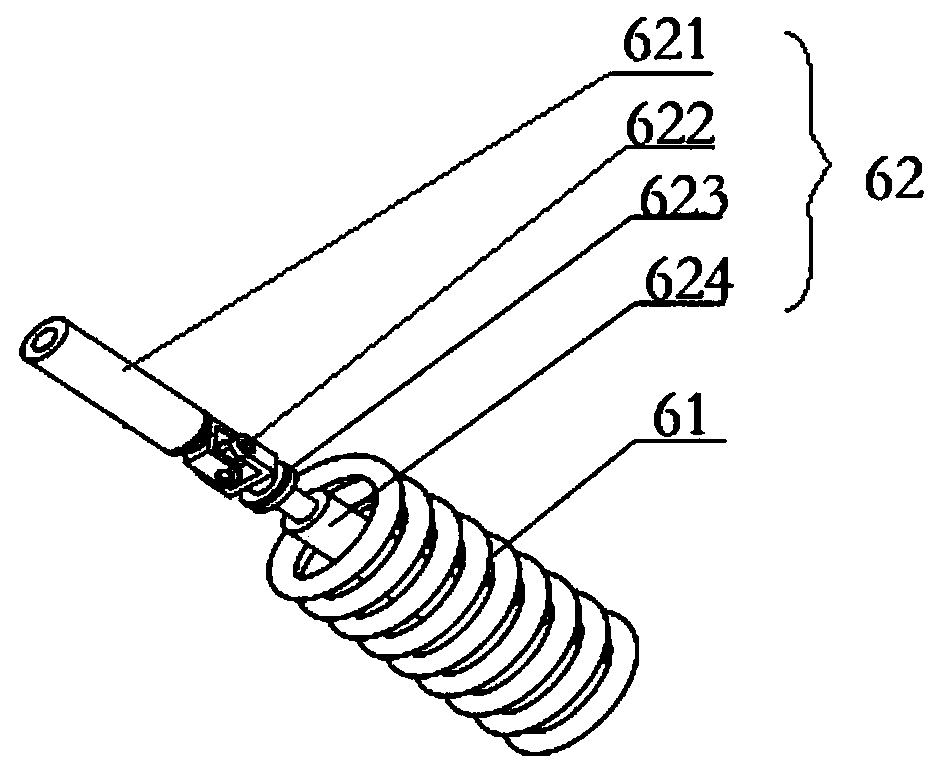

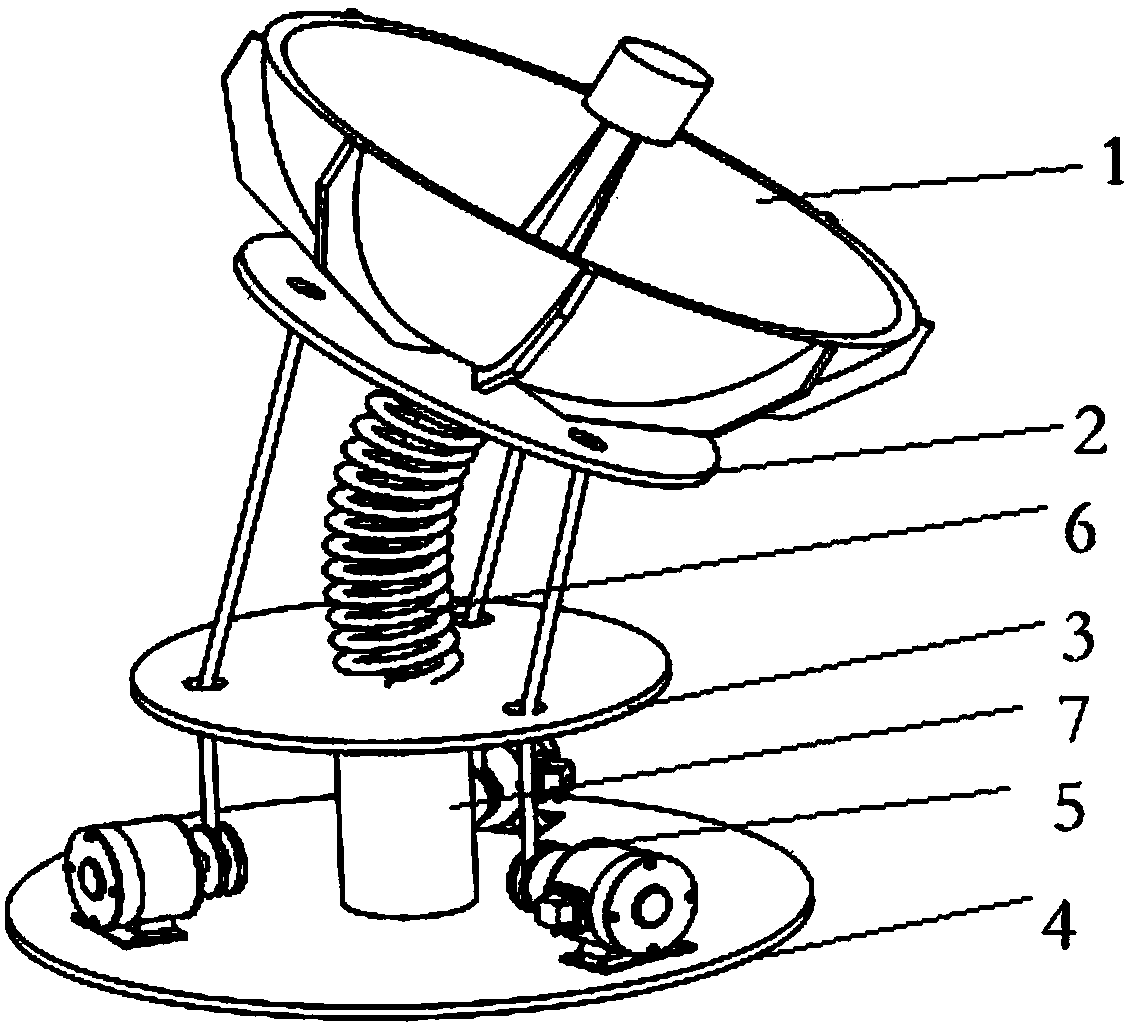

[0019] Such as figure 1 As shown, a parallel rope-driven antenna seat mechanism includes an antenna reflection surface 1, a moving platform 2, a fixed platform 3, a base platform 4, a support shaft 7, a central branch chain 6 and a rope driving device 5, and the antenna reflection surface 1 Fixed on the upper surface of the moving platform 2, the two ends of the central branch chain 6 are respectively fixed on the center position of the lower surface of the moving platform 2 and the upper surface of the fixed platform 3, and the two ends of the support shaft 7 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com