Full-automatic element separating and purifying device

A technology for element separation and purification equipment, applied in separation methods, solid adsorbent liquid separation, ion exchange, etc., can solve the problems of low efficiency of element separation and purification equipment, avoid experimental misoperation, complete separation, and prevent related safety accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

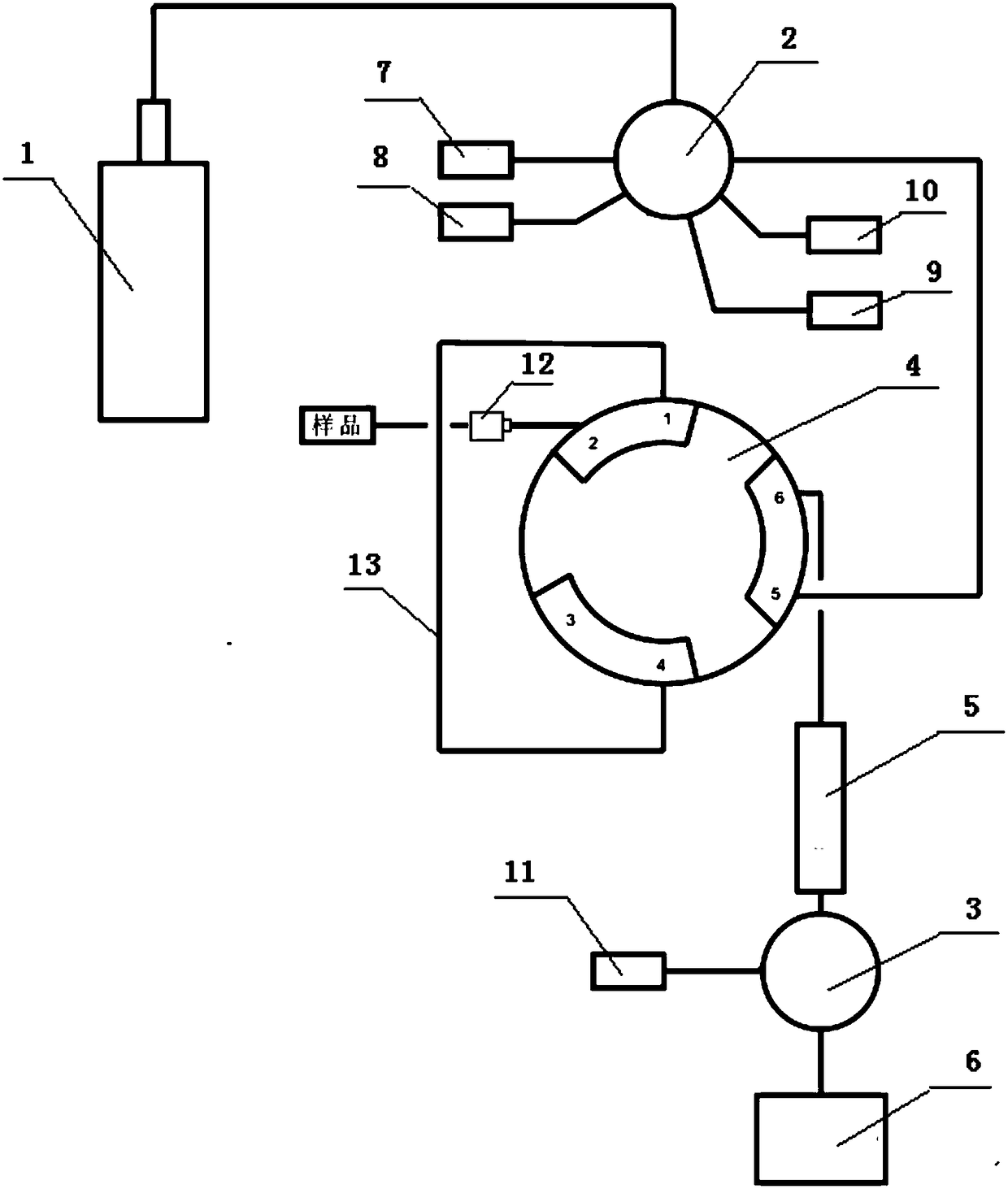

[0013] Such as figure 1 The fully automatic element separation and purification device shown includes a syringe pump 1, a first multi-channel switching valve 2, a second multi-channel switching valve 3, a two-position six-way valve 4, an ion chromatography column 5, and a collector 6. The syringe pump 1 is connected to the common port of the first multi-channel switching valve 2 with a tube not smaller than 1 / 8 inch, and the remaining ports of the first multi-channel switching valve 2 are respectively connected to the pure water tank 7, the eluent tank 8, and the concentrated acid tank. 9. The air tank 10 and the No. 5 port of the two-position six-way valve 4 are connected. The No. 1 port and No. 4 port of the two-position six-way valve 4 are connected by the sample loop 13, and the sample loop is not 1 / 8-inch tube less than 5cm, the No. 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com