Coating processing device based on rotating grinding dispersion principle

A technology of grinding, dispersing and processing equipment, applied in the field of coatings, can solve the problems of poor dispersion effect and difficulty in meeting production requirements, and achieve the effect of improving the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

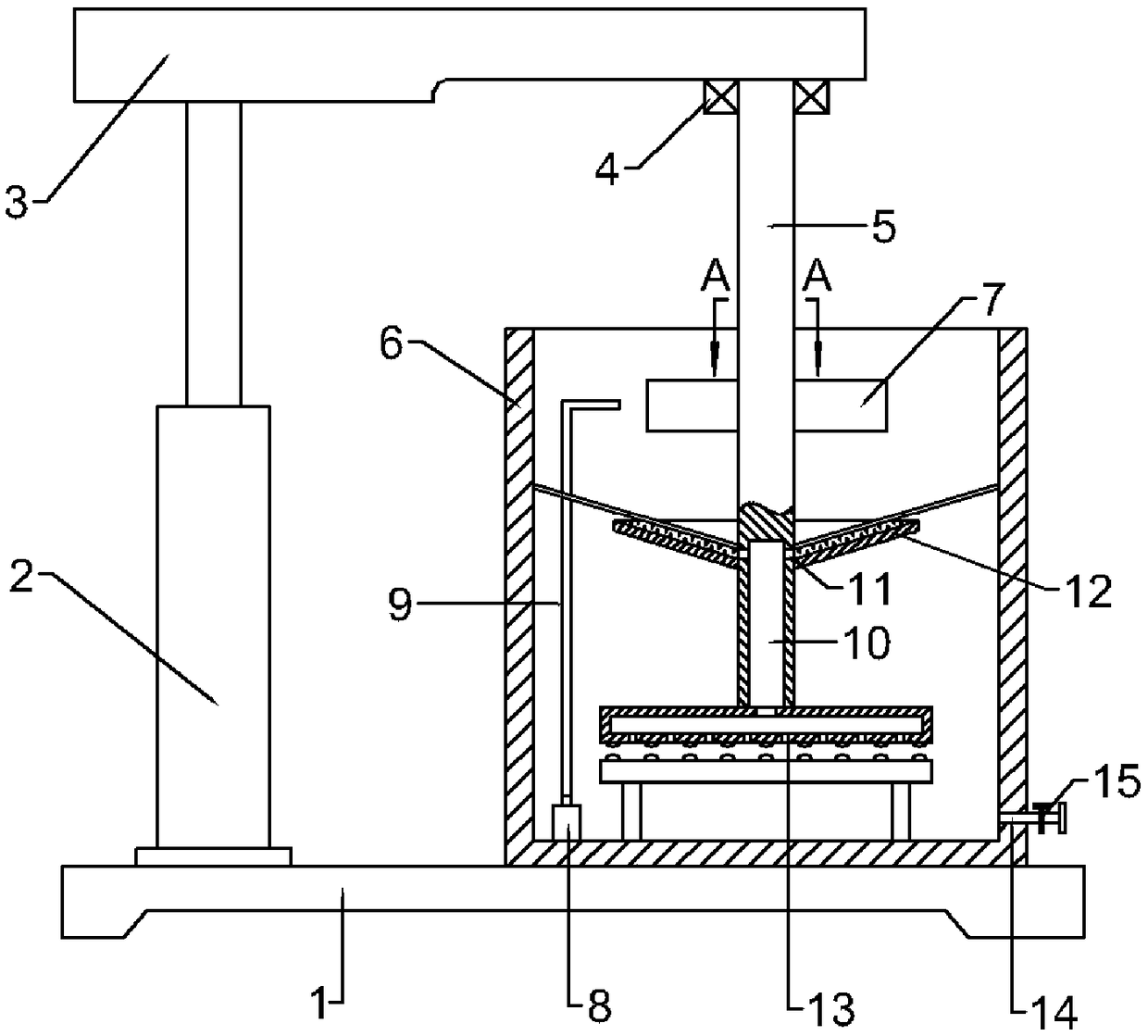

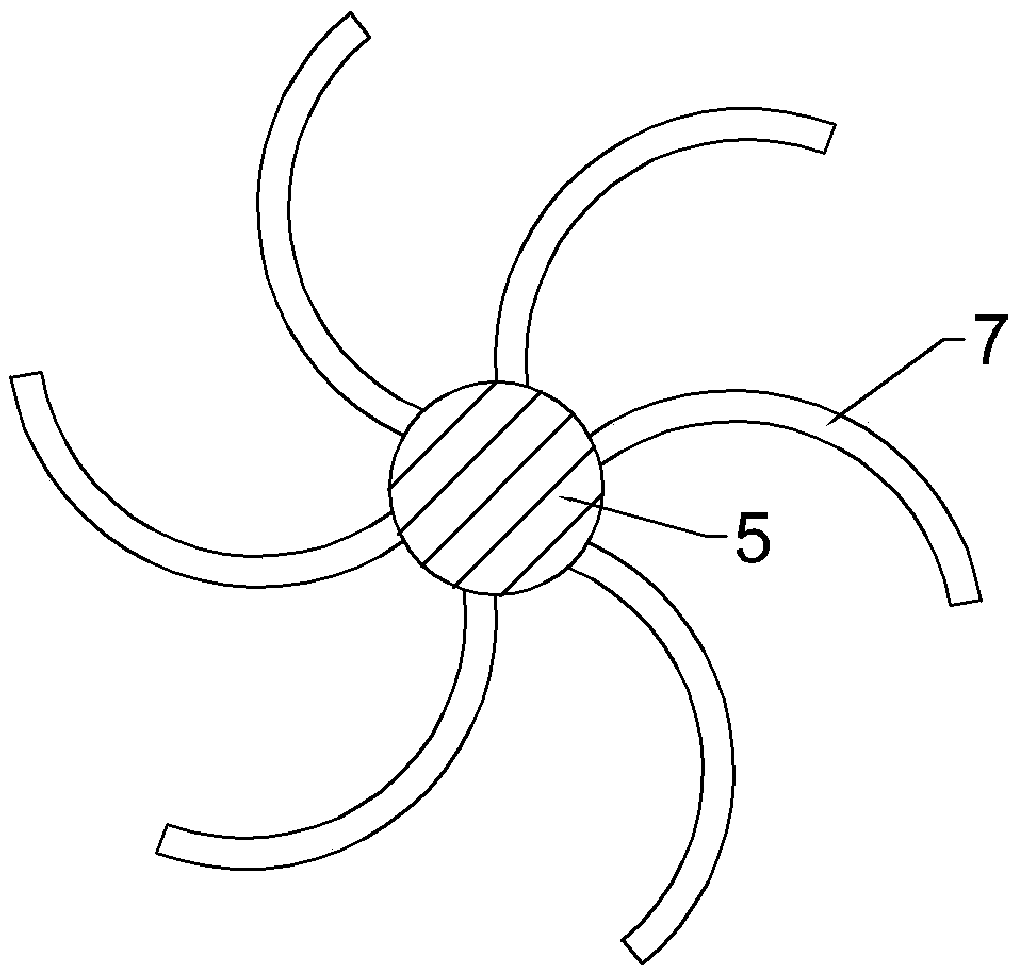

[0026] see figure 1 with figure 2 , in the embodiment of the present invention, a paint processing equipment based on the principle of rotary grinding and dispersion, including a base 1, a hydraulic telescopic cylinder 2 is fixedly connected to the upper side of the base 1, and a cantilever beam 3 is fixedly connected to the top of the hydraulic telescopic cylinder 2, and the cantilever beam 3. The lower end of the right side is fixedly connected with a bearing 4, and the inner ring of the bearing 4 is fixedly connected with a rotating shaft 5. A dispersing barrel 6 is placed on the upper side of the base 1, and the rotating shaft 5 extends to the inside of the dispersing barrel 6. The upper part of the rotating shaft 5 is fixedly connected with several Rotating vane 7, pump body 8 is arranged on the inner bottom of dispersing barrel 6, is connected with pipeline 9 on the pump body 8, and the outlet of pipeline 9 is facing the rotating blade 7, starts pump body 8 during work,...

Embodiment 2

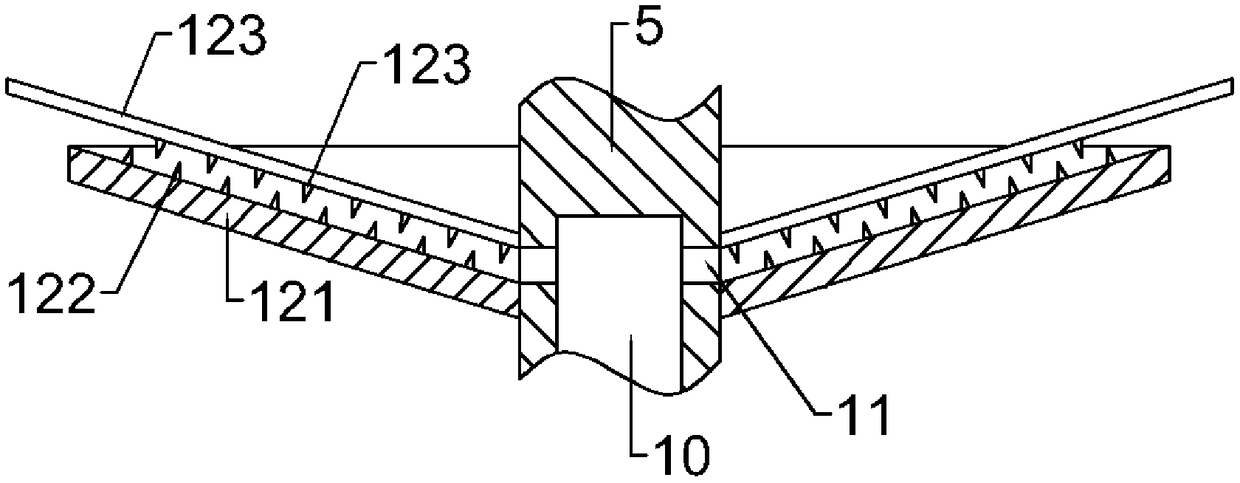

[0028] see figure 1 with image 3 The first rotating grinding device 12 is arranged outside the rotating shaft 5, and the first rotating grinding device 12 includes a grinding bucket 121. The grinding bucket 121 is arranged on the side wall of the rotating shaft 5 in a funnel shape, and the upper side of the grinding bucket 121 is evenly arranged There are a number of first grinding protrusions 122; the inner wall of the dispersion bucket 6 is symmetrically fixedly connected with a number of grinding rods 123, and the lower side of the grinding rod 123 is evenly arranged with a number of first grinding protrusions 122, which act on the liquid on the rotating blade 7. The paint falls into the grinding bucket 121 under the action of gravity, and the rotating shaft 5 drives the grinding bucket 121 to rotate, and the first grinding protrusion 122 arranged on the lower side of the grinding rod 123 grinds the liquid paint in the grinding bucket 121, thus playing the first important ...

Embodiment 3

[0030] see figure 1 The inside of the rotating shaft 5 is provided with a cavity 10, and the cavity 10 communicates with the first rotating grinding device 12 through a plurality of communication holes 11 provided on the side wall of the rotating shaft 5; a second rotating grinding device 13 is arranged below the rotating shaft 5, The liquid paint in the grinding bucket 121 enters the cavity 10 through the communication hole 11, and then enters the second rotating grinding device 13 to be dispersed; the bottom of the dispersion bucket 6 is provided with a discharge channel 14, and the discharge channel 14 A valve 15 is provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com