Roxburgh rose sorting system based on machine vision

A technology of mechanical vision and sorting system, which is applied in sorting, analyzing materials, and analyzing materials by optical means. It can solve the problems of uncombined and improve sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

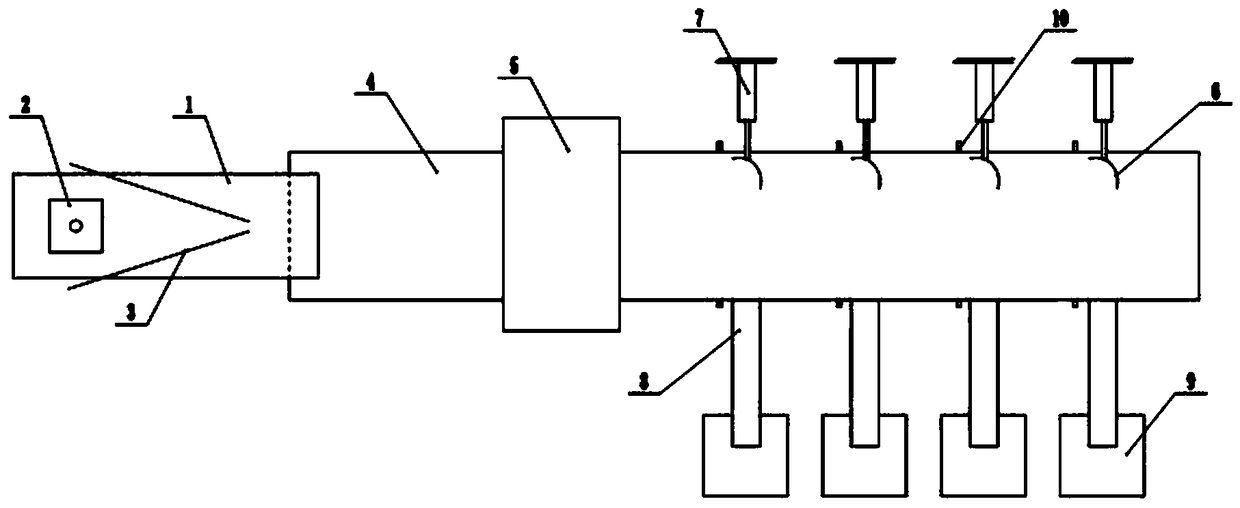

[0018] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

[0019] Please refer to figure 1 According to a kind of prickly pear sorting system based on machine vision of the present invention, comprise detection conveyor 4, detection conveyor 4 is a conventional belt conveyor, in the upstream position of detection conveyor 4 is provided with machine vision recognition system 5, with It is used to identify the color and / or size of the thorn pear; a pushing and diverting mechanism is arranged at the downstream position of the detection conveyor 4, so as to push the thorn pear to different shunting channels 8 according to the color and / or size of the thorn pear, and complete the thorn pear Classification.

[0020] The machine vision identification system 5 is an existing conventional device, which is provided with a camera for obtaining the color and the size of the thorn pear passing through the detection conveyor 4.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com