Automatic foundry production line control system and control method

A foundry production line and control system technology, applied in foundry workshops, foundry equipment, manufacturing tools, etc., can solve the problems of high professional level requirements for operators, product quality is affected by subjective factors, and increase the cost of enterprise employment, so as to reduce operation Reliance on personnel, simplification of automatic control, and the effect of reducing enterprise costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

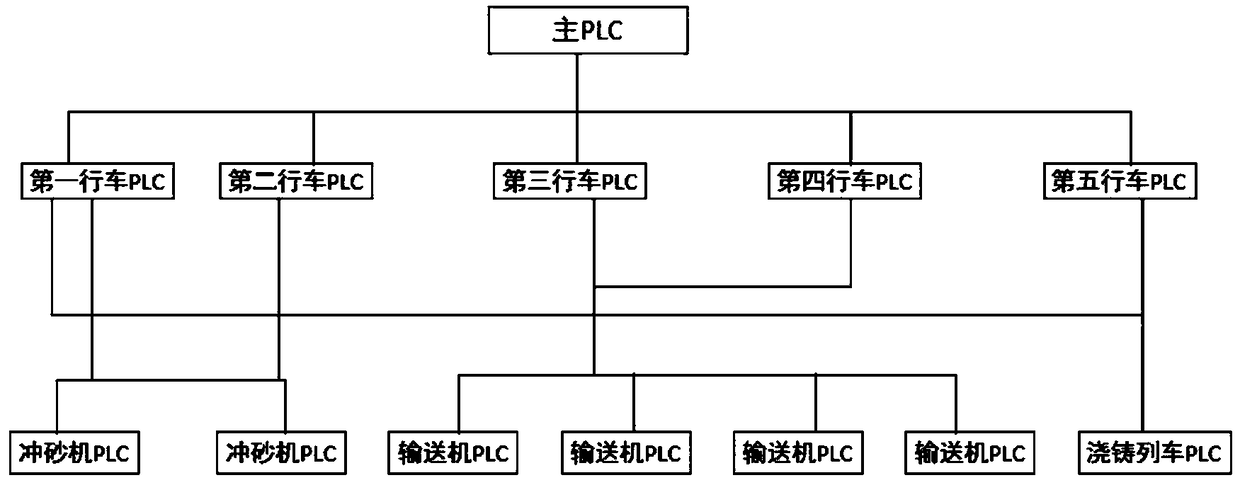

[0019] like figure 1 As shown, the present invention proposes a control system for an automatic casting production line, which includes several sand washing machines, several conveyors, casting trains, several trains, a main PLC, multiple train PLCs and multiple on-site PLCs, the main PLC, multiple Each driving PLC and multiple on-site PLCs all adopt the PLC model SMS-S7-200, and the main PLC is respectively connected to multiple driving PLCs and multiple on-site PLCs, and the multiple driving PLCs correspond to several driving PLCs respectively. Control connection, a plurality of on-site PLCs are respectively connected with a number of sand washing machines, a number of conveyors and casting trains in one-to-one correspondence, and the main PLC, a plurality of driving PLCs and a plurality of on-site PLCs communicate with each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com