Big size polaroid attaching device

A polarizer attachment and polarizer technology, which is applied in optics, nonlinear optics, lamination auxiliary operations, etc., can solve the problems of large-size liquid crystal display rework and the inability to meet the process requirements of large-size liquid crystal polarizer attachment. , to achieve the effect of reducing enterprise costs and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

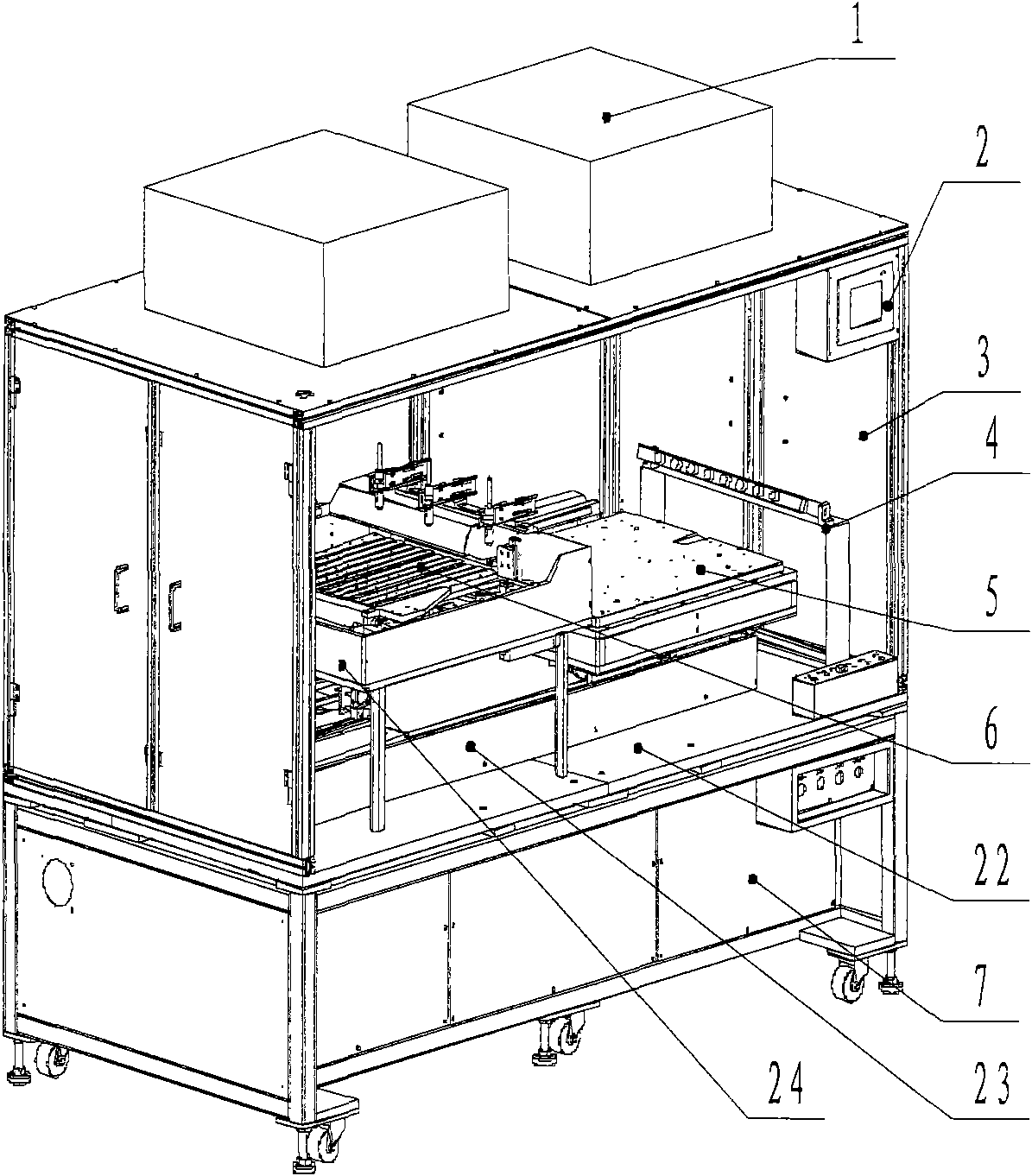

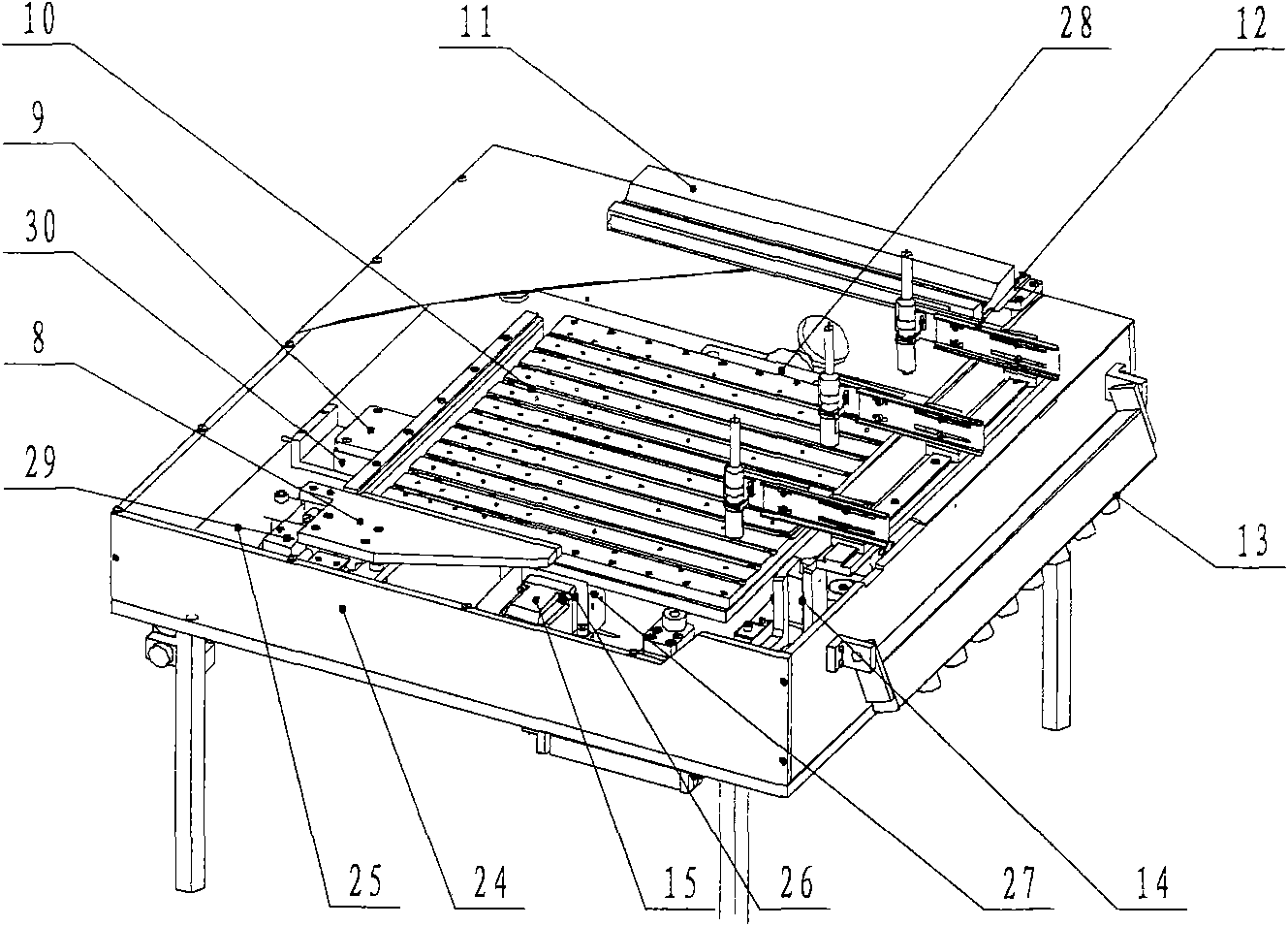

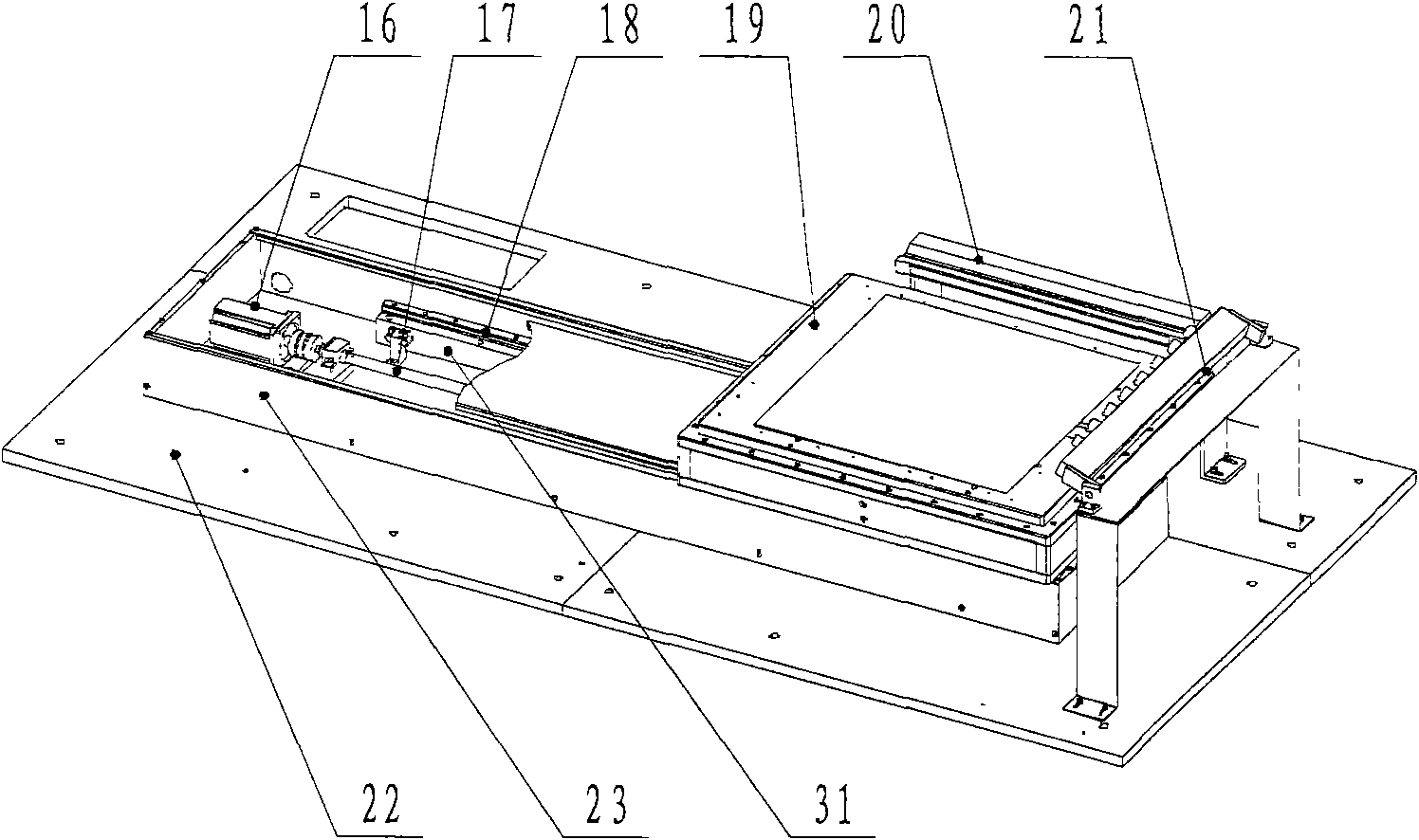

[0013] The large-size polarizer attaching equipment includes a lower frame 7, a box-shaped cover upper frame 3 arranged on the lower frame 7, a programmable controller 2, an attachment head 14 arranged on the polarizer platform part 6, The liquid crystal glass platform part 5 and the polarizer platform part 6 arranged in the upper frame 3 of the box-shaped cover body, the described liquid crystal glass platform part 5 is arranged on the right half area of the platen 22 of the lower frame, and the described polarizer The platform part 6 is arranged on the polarizer workbench box-shaped support frame 24 on the left half area of the platen 22 of the lower frame; The servo motor 16 below the platform part 6, the output shaft of the servo motor 16 is fixedly connected with a lead screw 17, the lead screw 17 is provided with a lead screw nut, and the lead screw nut is fixedly connected with the liquid crystal glass workbench 19. Plate 22 is provided with guide rail mounting bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com