Catalyst based on varisized platinum-zinc nanoparticles loaded on zinc-containing monatomic carbon-nitrogen carrier, preparation method and application thereof

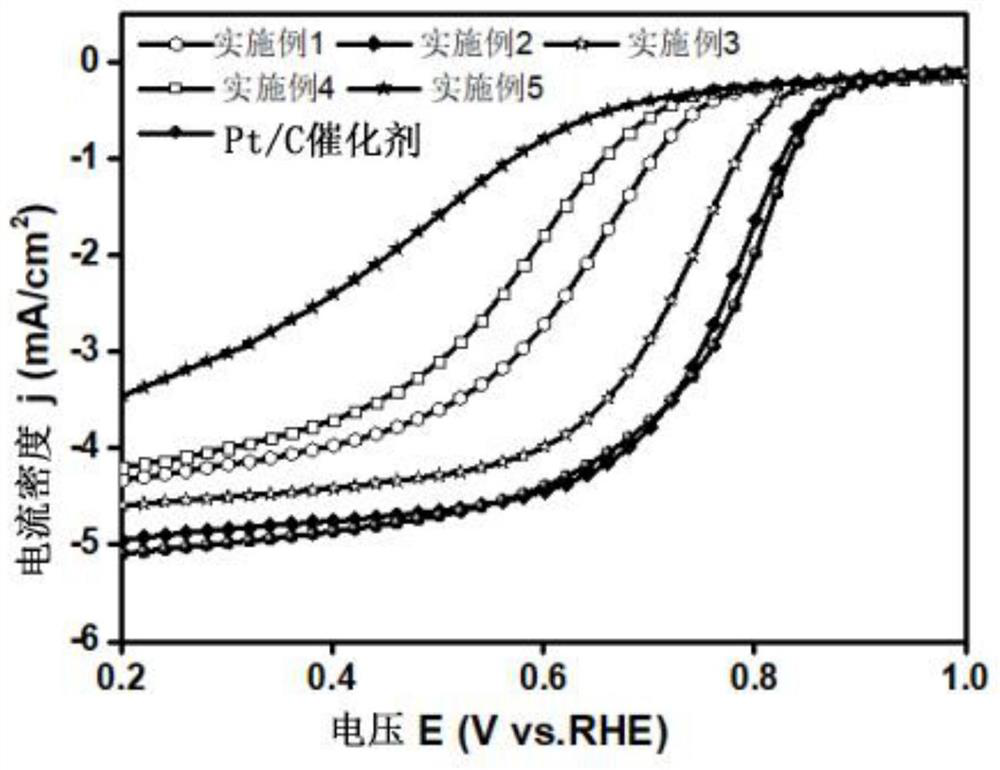

A platinum nanoparticle and nanoparticle technology is applied to catalysts based on platinum and zinc nanoparticles of different sizes supported on zinc-containing single-atom carbon-nitrogen carrier catalysts and their preparation and application fields, which can solve the problems of short life and high catalyst toxicity, and achieve low Platinum loading, high catalytic activity, effect of reducing commercial cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

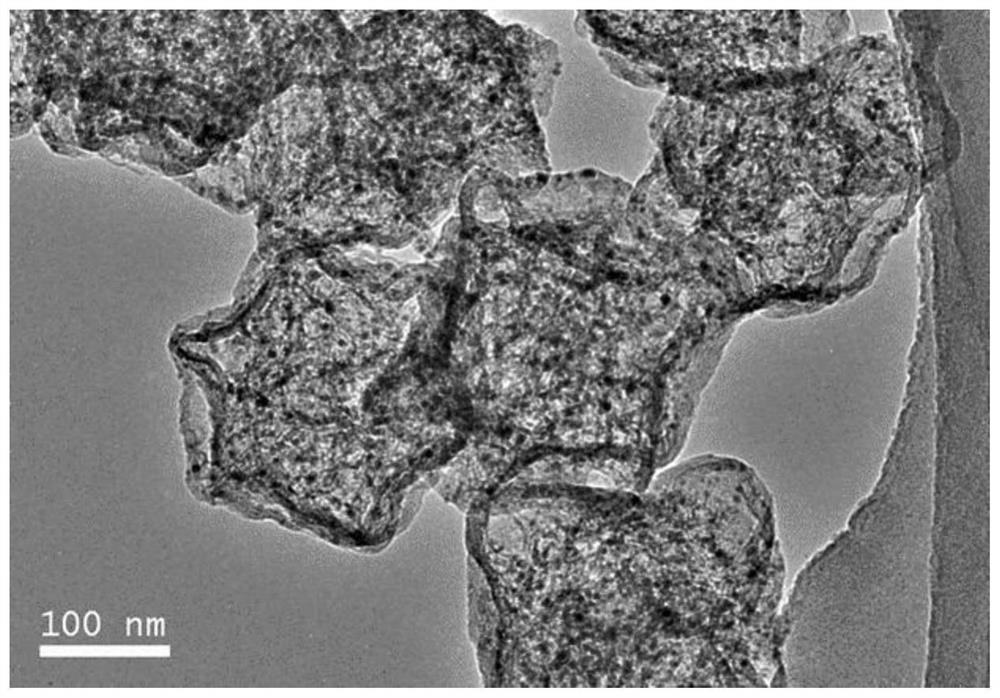

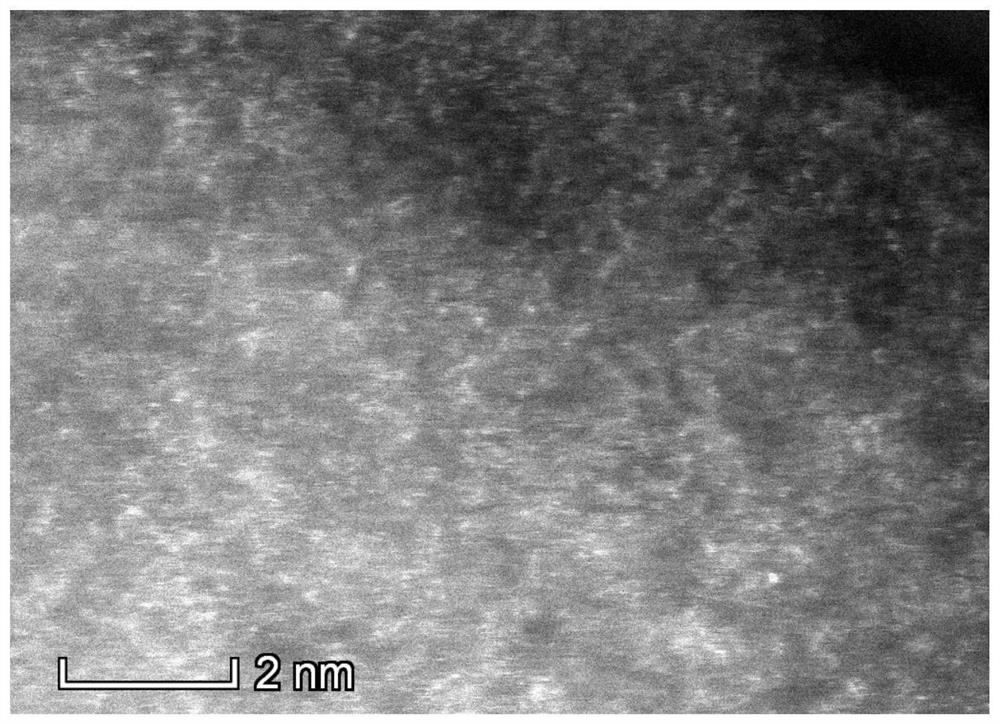

[0032]The preparation of a catalyst based on 2.2 nm platinum-zinc nanoparticles supported on a zinc-containing single-atom carbon-nitrogen carrier comprises the following steps:

[0033] 1) Add 3.25 mL of ethylene glycol solution containing NaOH (the mass of NaOH is 62.5 mg) to 3 mL containing H 2 PtCl 6 ·6H 2 O(H 2 PtCl 6 ·6H 2 O mass is 0.0625 g) in ethylene glycol solution. Under nitrogen blowing conditions, the mixture was heated to 160 °C and stirred at constant temperature for 3 h. After cooling at room temperature, 1 mL of 2 M HCl solution was added to obtain platinum nanoparticles, and the precipitate was obtained by centrifugation and dispersed in 20 mL of methanol solution containing 3 mg of PVP (Mw = 24000, the same below), and finally the platinum-containing Methanol suspension of nanoparticles (platinum nanoparticles solubility is approximately 1.17 mg / mL).

[0034] 2) Take 20 mL of the suspension containing platinum nanoparticles obtained in step 1), add i...

Embodiment 2

[0041] The preparation of a catalyst based on 3.7 nm platinum-zinc nanoparticles loaded on a zinc-containing single-atom carbon-nitrogen carrier comprises the following steps:

[0042] 1) Dilute 20 mL H 2 PtCl 6 ·6H 2 O (concentration of 6.0 mM) aqueous solution was added to 180 mL of methanol solution containing 533 mg of PVP, and the mixture was heated to 100 °C under a nitrogen atmosphere and kept stirring at constant temperature for 3 h. Finally, the resulting mixture was cooled to room temperature, and the volume of the mixture was evaporated to 10 mL by rotary evaporation. The evaporation residue was added to excess acetone to obtain a precipitate, and finally the precipitate was dispersed in 20 mL of methanol to obtain a methanol suspension containing platinum nanoparticles (the solubility of platinum nanoparticles was about 1.17 mg / mL).

[0043] 2) Take 20 mL of the suspension containing platinum nanoparticles obtained in step 1), add it to 20 mL of methanol solutio...

Embodiment 3

[0051] The preparation of a catalyst based on 4.5 nm platinum-zinc nanoparticles supported on a zinc-containing single-atom carbon-nitrogen carrier comprises the following steps:

[0052] 1) Take 20 mL of the suspension containing platinum nanoparticles freshly prepared in step 1 of Example 2, add to 170 mL methanol solution and 10 mL H 2 PtCl 6 ·6H 2 O (concentration: 6.0 mM) aqueous solution, the mixture was heated to 100 °C under nitrogen atmosphere and kept stirring at constant temperature for 3 h. Finally the resulting mixture was cooled to room temperature and the volume of the mixture was evaporated to 10 mL by rotary evaporation. The evaporation residue was added to excess acetone to obtain a precipitate, which was finally dispersed in methanol to obtain a suspension containing platinum nanoparticles (the solubility of platinum nanoparticles was about 1.17 mg / mL).

[0053] 2) Take 20 mL of the suspension containing platinum nanoparticles obtained in step 1), add it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com