Lock pipe fully-automatic numerical control machining equipment

A processing equipment, fully automatic technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of inability to process multiple equipment at the same time, low processing efficiency, complex processing process, etc., to improve work efficiency and production efficiency , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

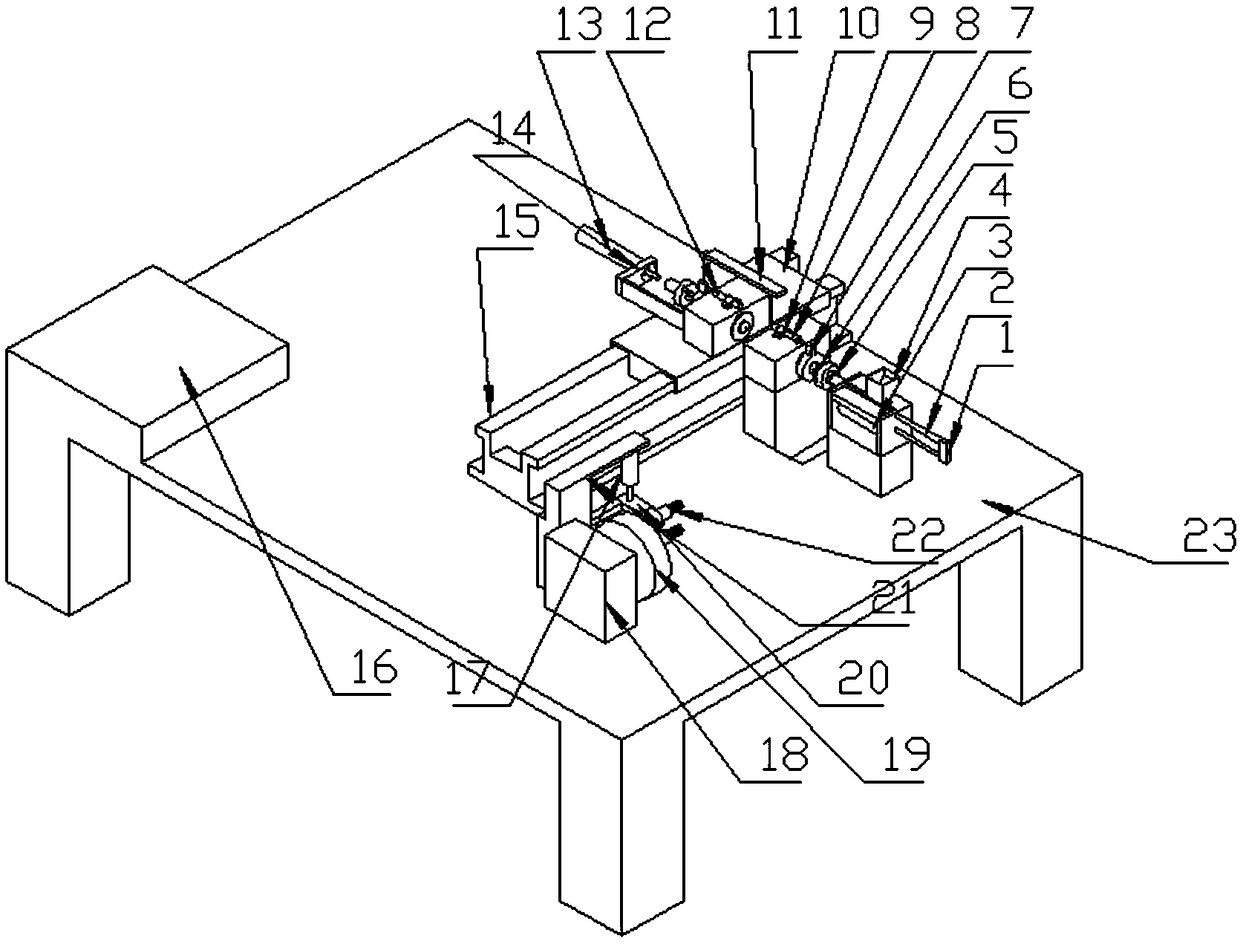

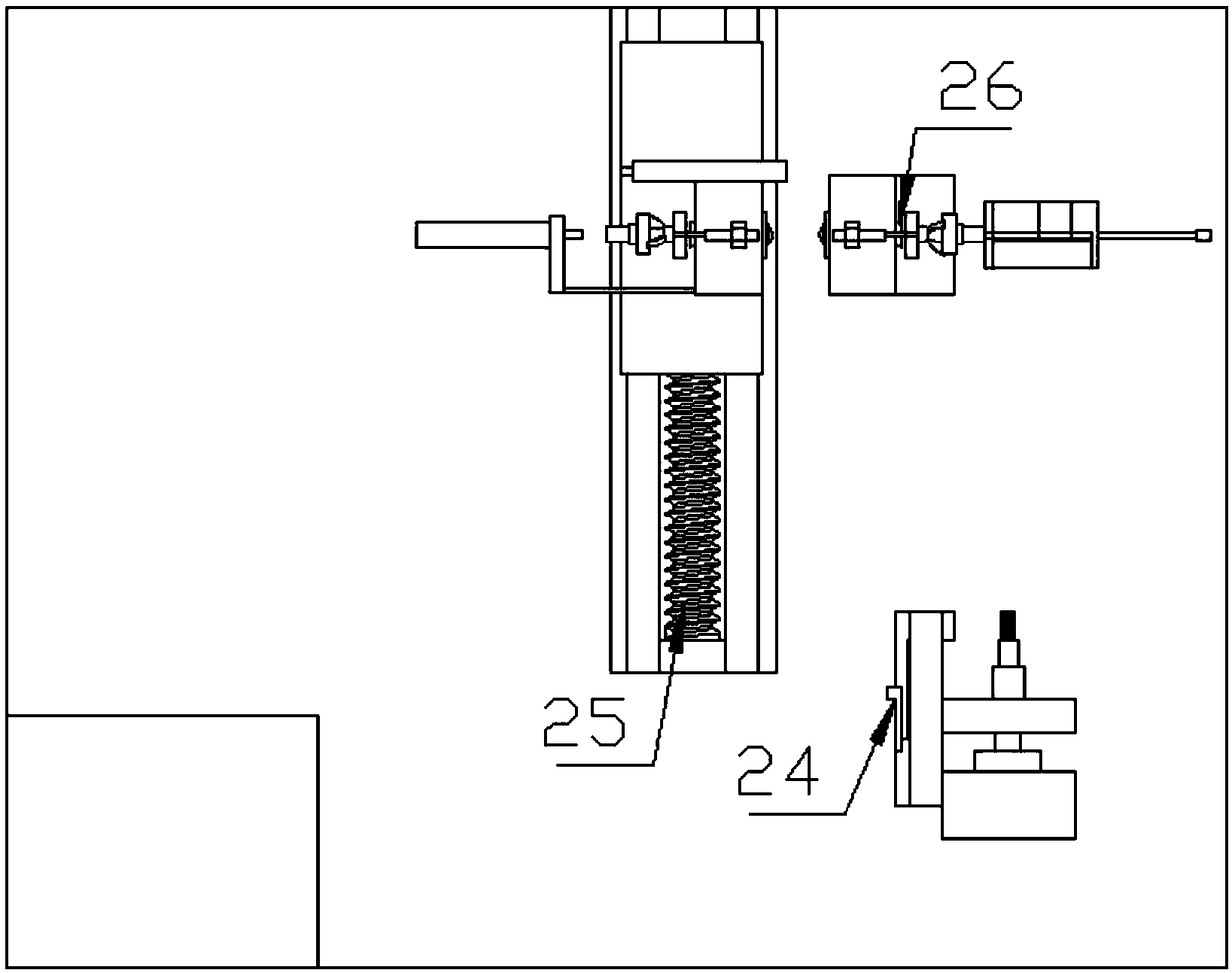

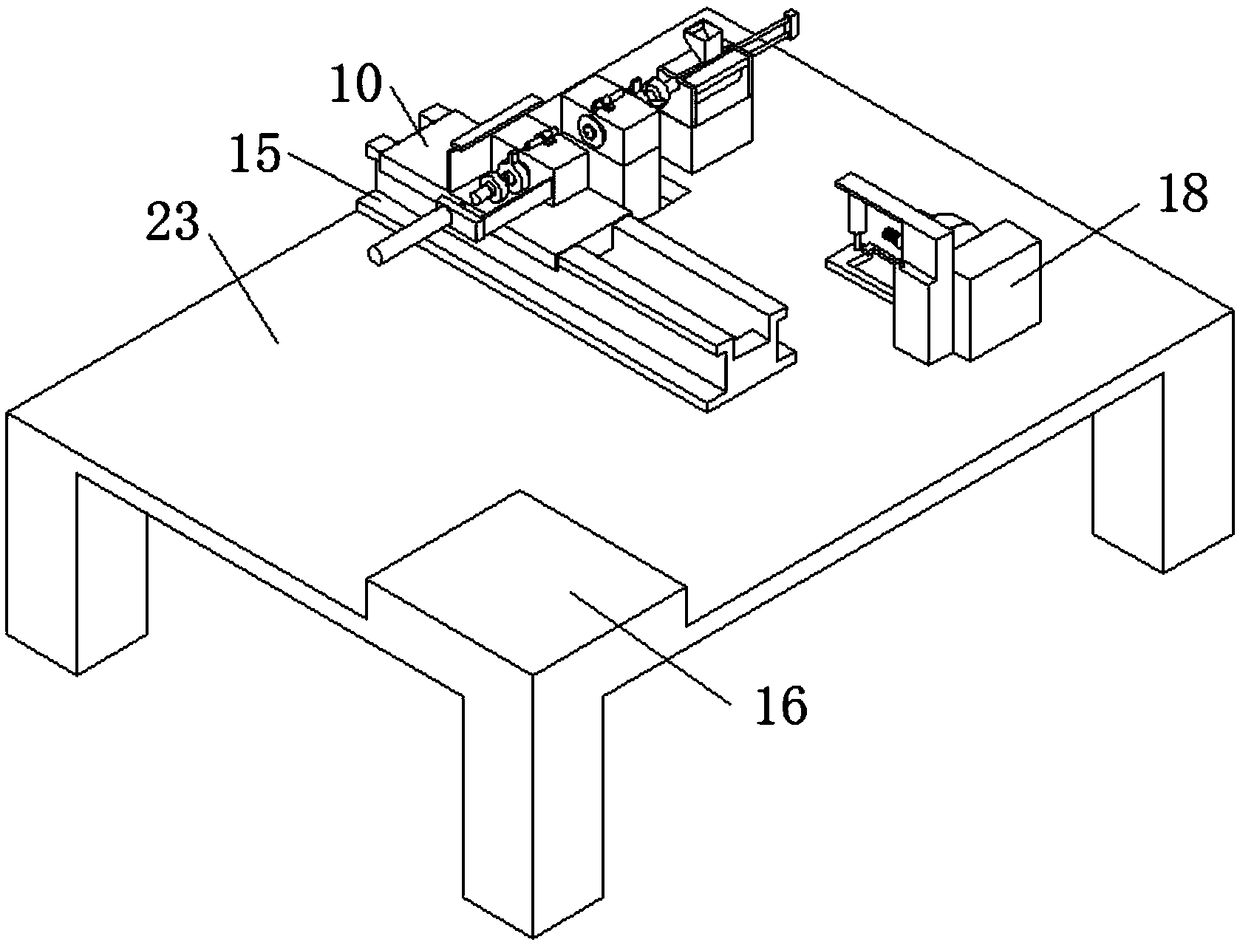

[0017] refer to Figure 1-3 , fully automatic numerically controlled processing equipment for locked tubes, comprising a frame 23 and a control cabinet 16, characterized in that a slide rail 15 is provided at the top middle of the frame 23, and ball wires are fixed in the top chute of the slide rail 15 A bar nut pair 25, the nut of the ball screw nut pair 25 is connected with a slider 10, the top of the slider 10 is provided with a left cylinder fixed support, and the top of the left cylinder fixed support is respectively provided with a lock The left end of the pipe is processed with a tool 11 and a left cylinder 12. One side of the left cylinder 12 is fixed with an outer cylinder fixed support 14, and the side of the outer cylinder fixed support 14 away from the left cylinder 12 is fixed with an outer cylinder 13. The other side of the top of the frame 23 is provided with a right cylinder fixed support 9 and a motor 18 arranged side by side front and back, and the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com