Optimization of an automated process for selecting and gripping an object by a robot

A robot and object technology, applied in the direction of instruments, manipulators, program control, etc., can solve the problems of robot standby time and non-production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the figures, functionally identical elements are provided with the same reference symbols unless otherwise stated.

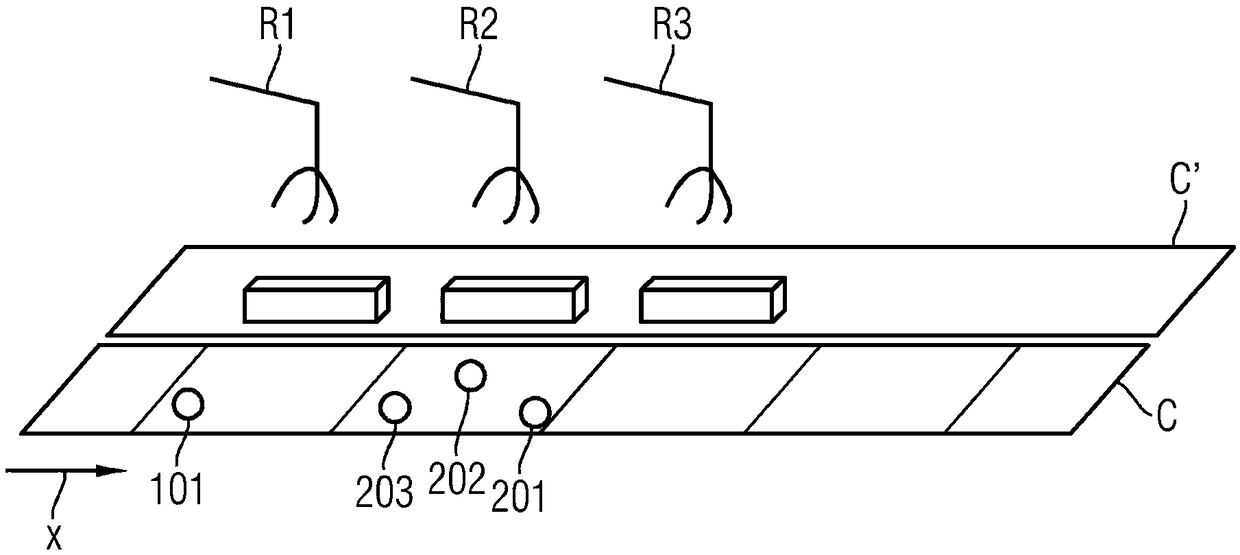

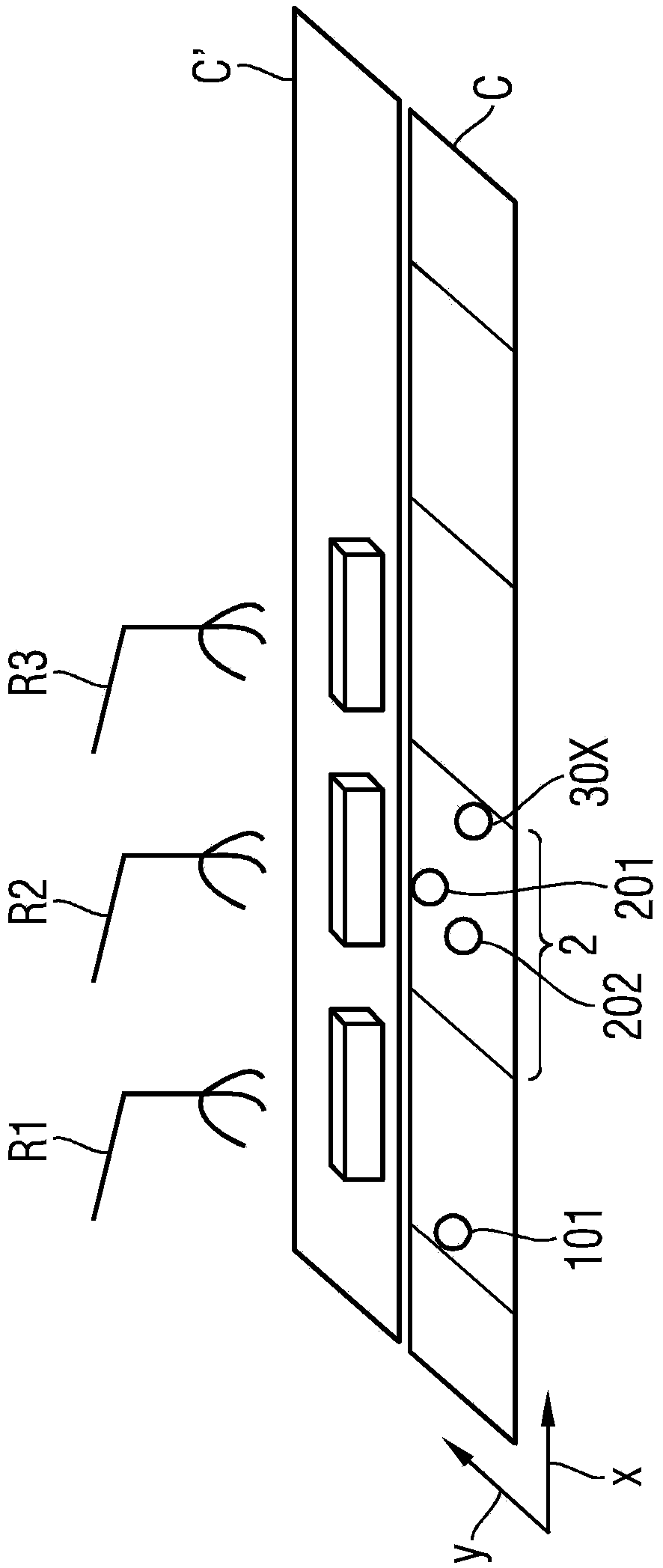

[0040] exist figure 1 How the objects 101 , 203 , 202 , 201 are arranged on the conveyor belt C is schematically shown in . An example would be individual products wrapped in plastic film in a packaging facility, ready to be stacked into cartons. For example every six individual products are packed into a carton and are thus delivered as a product. To this end, objects 101 , 203 , 202 , 201 are picked up from a conveyor belt C by robotic gripping arms R1 , R2 , R3 and lifted into cartons on another conveyor belt C′. For clarity, only a few objects are shown.

[0041] In a real packaging facility, the products appear on the conveyor belt C irregularly and unregulated. For example, they fall off a conveyor belt that was previously in the manufacturing facility. For example in the last step of the process a plastic film is wound around the product an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com