Double-lead-screw clamping feeding type pineapple peeling and dicing machine

A technology of double screw and dicing machine, which is applied to peeling utensils, kitchen utensils, household utensils, etc., can solve the problems of high cost, waste, complicated device structure, etc., achieve completeness and rapidity, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

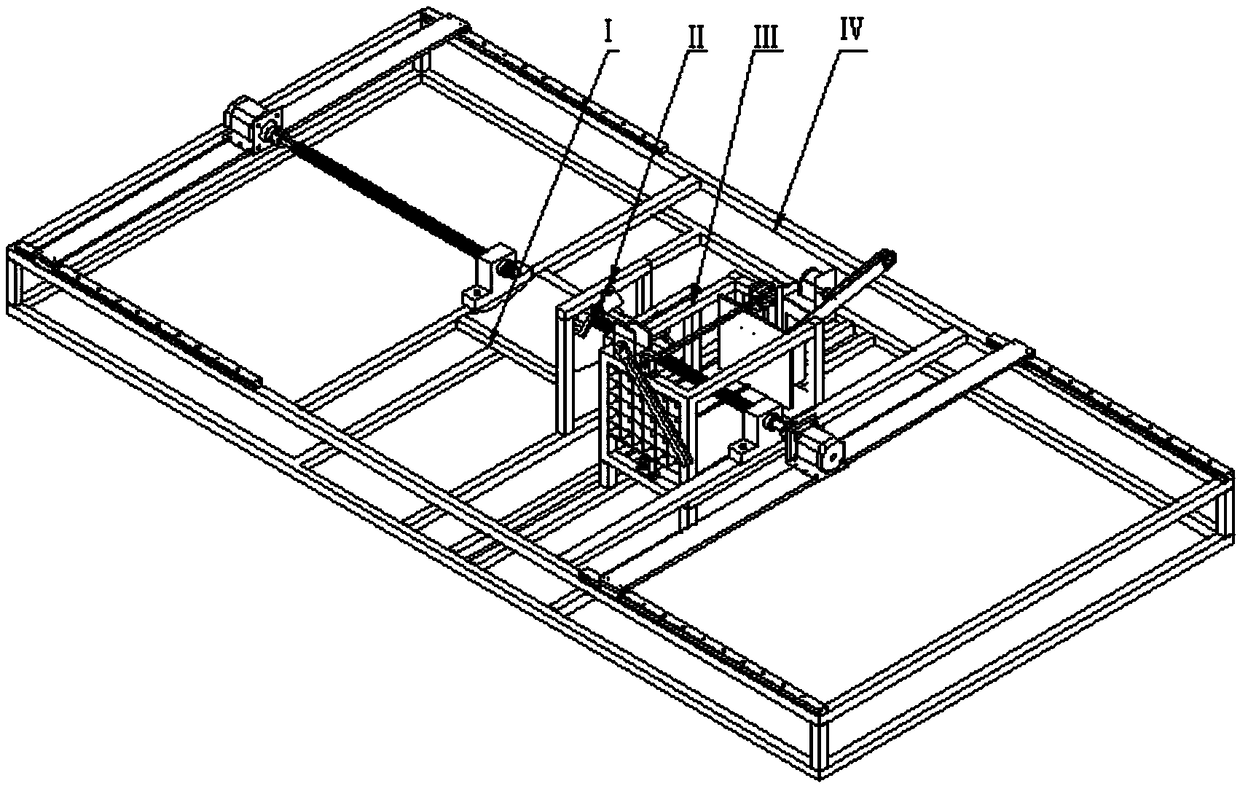

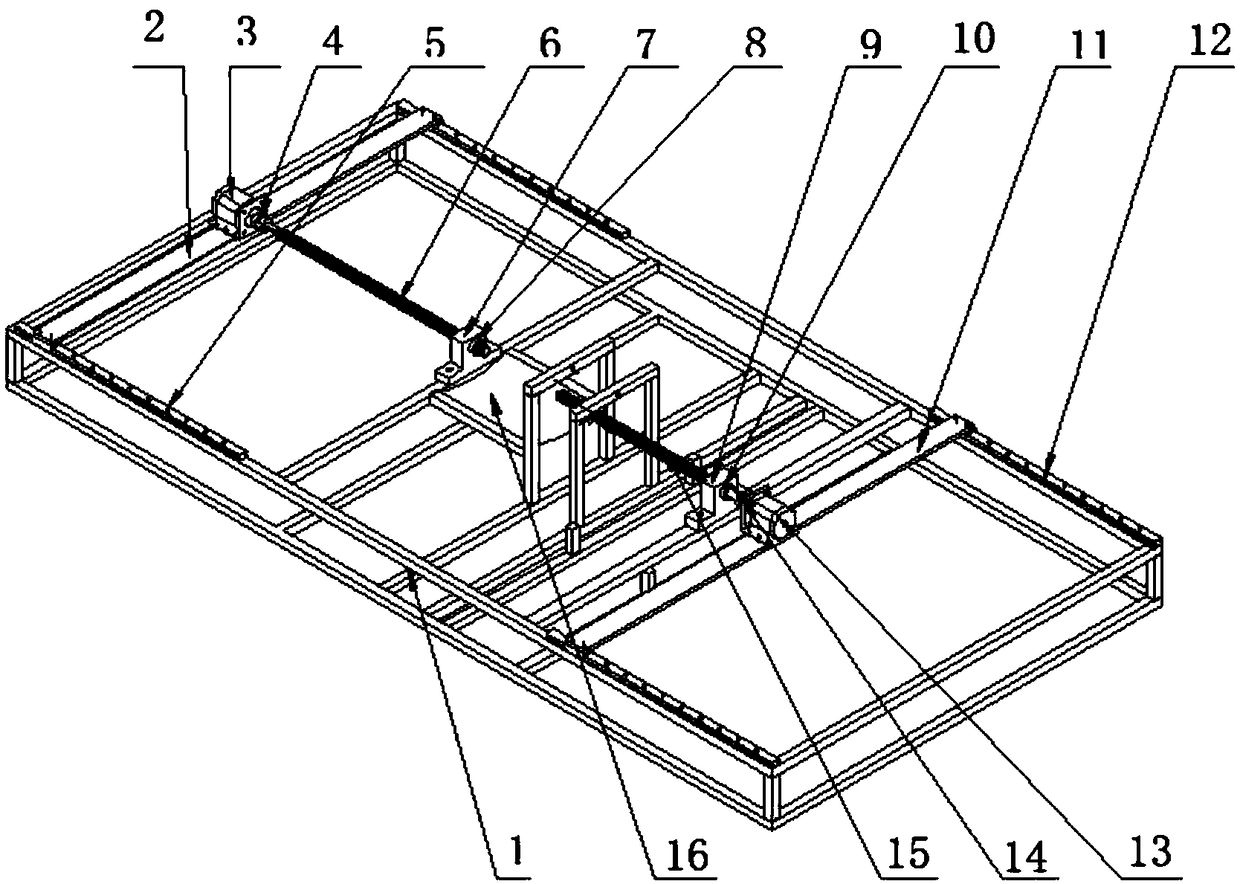

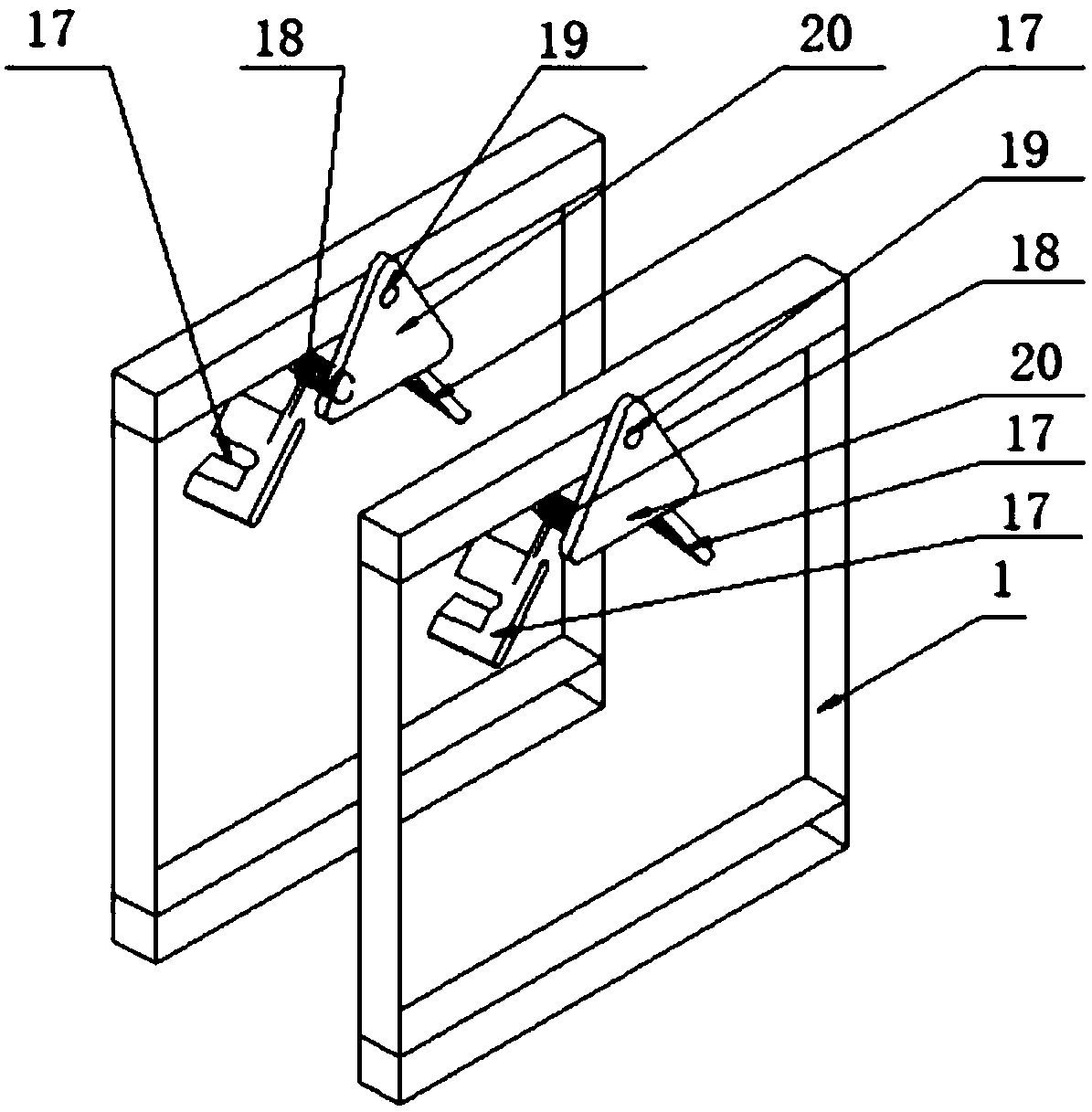

[0018]The main structure of a pineapple peeling and dicing machine with double screw clamping and feeding involved in this embodiment includes a frame 1, a front support plate 2, a front stepping motor 3, a front coupling 4, and a front strip slide rail 5. Front screw 6, front vertical shaft support 7, front nut 8, rear vertical shaft support 9, rear nut 10, rear support plate 11, rear strip slide rail 12, rear stepping motor 13 , rear coupling 14, rear screw 15, arc-shaped bottom plate 16, blade 17, torsion spring 18, bolt 19, triangular support plate 20, rotating blade 21, grid knife 22, bearing support 23, push plate motor 24 , push pedal slide rail 25, push pedal bearing 26, blade motor 27, crank coupling 28, crank 29, connecting rod 30, push pedal 31, receiving base plate 32; frame 1 is a frame structure, so that support and fix each Components; the front stepper motor 3 is fixed in the middle of the front support plate 2 by fastening screws, and the two ends of the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com