Device and method for processing PBX (polymer bonded explosive) composite containing hard foreign material

A technology of composite materials and foreign objects, which is used in milling machines, metal processing equipment, workpieces, etc., can solve the problems of workpiece scrap, economic loss, affecting product surface, etc., and achieve high yield, high economic value, and high cutting speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

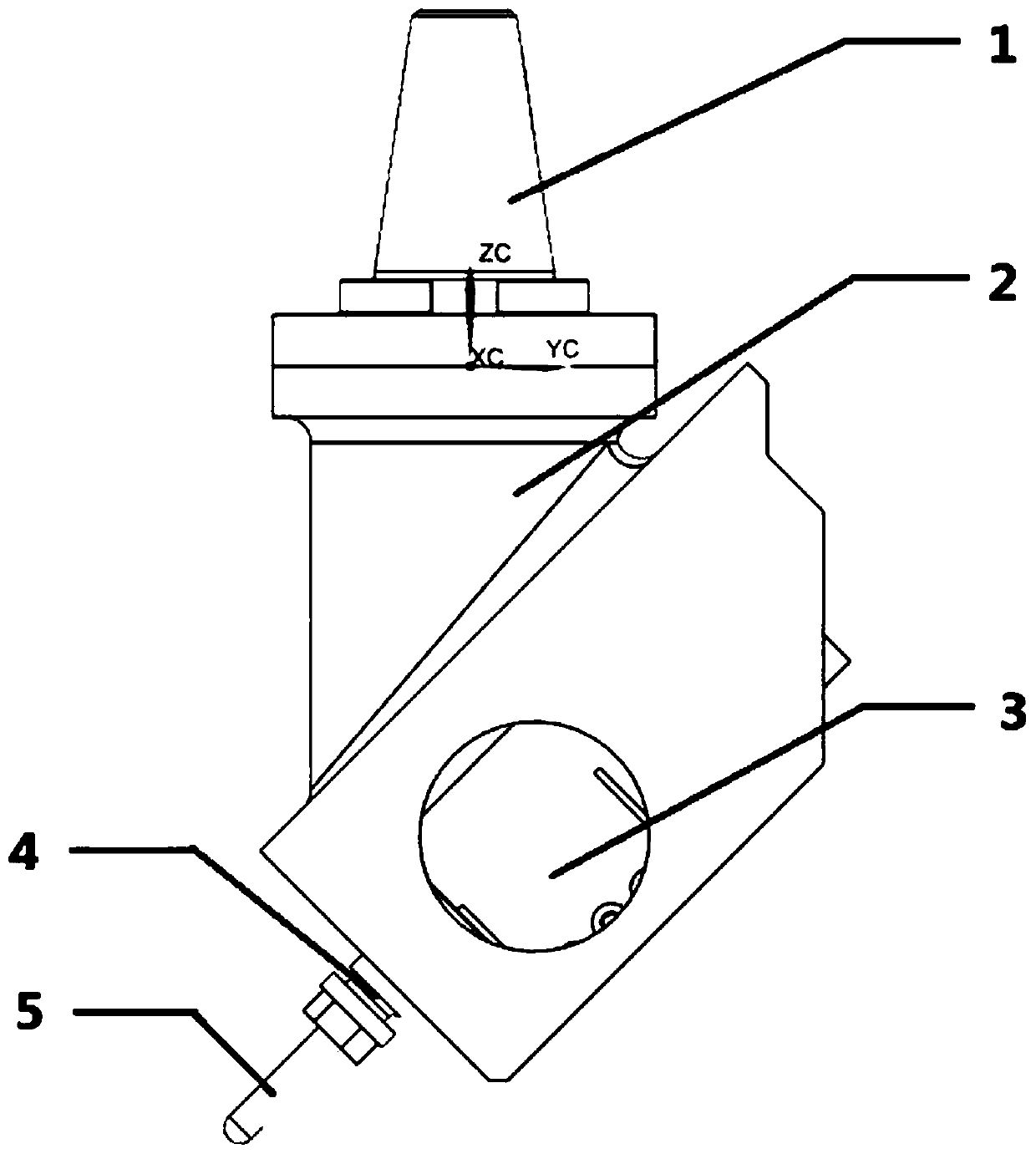

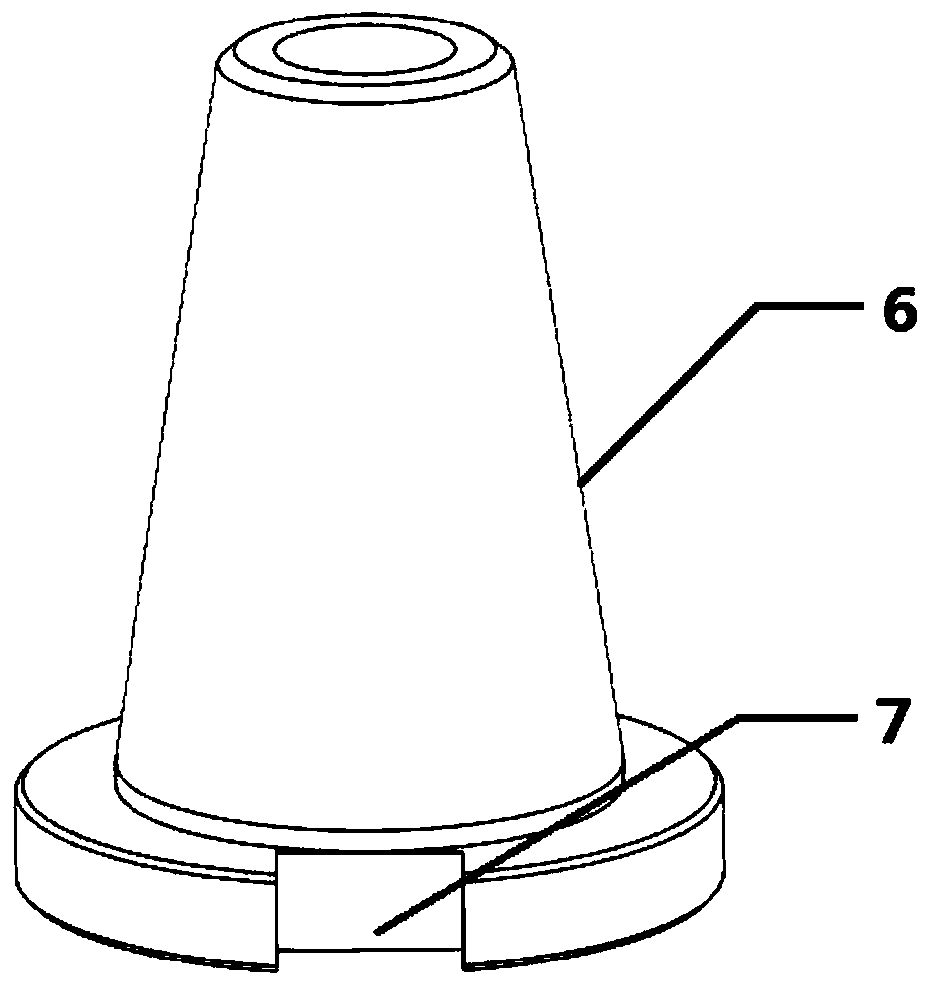

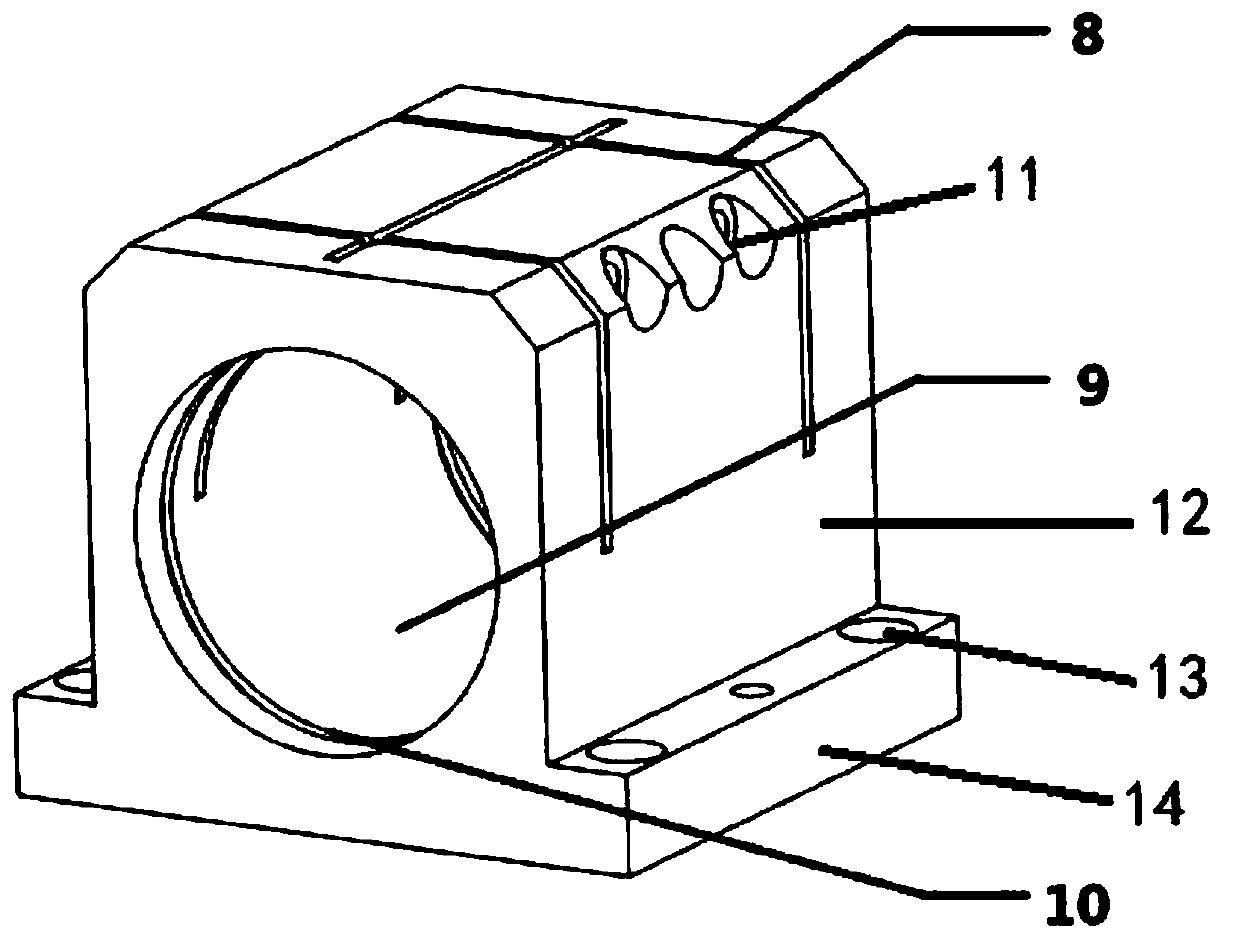

[0032] like figure 1 As shown, a device for processing PBX composite materials containing hard foreign matter, including tool holder 1, connection box 2, spindle jacket 3, electric spindle 4 and ball end milling cutter 5, tool holder 1 is a transition connection structure, the top of the tool handle 1 is fixedly connected to the Z-axis ram of the CNC vertical lathe, the bottom of the tool handle 1 is fixedly connected to the connection box 2, the spindle jacket 3 is set in the connection box 2, and the bottom of the connection box 2 is set There is a through hole, the electric spindle 4 passes through the hole and is set on the spindle jacket 3, the ball end milling cutter 5 is set outside the connection box 2 and is fixedly connected with the electric spindle 4, in this embodiment, the electric spindle 4 is set by a spring clip Clamp ball end milling cutter5. In this embodiment, the electric spindle 4 is selected from the HF 80.14S 15CPS type electric spindle 4 of the Swiss ...

Embodiment 2

[0048] The device adopted in this embodiment is the same as that of embodiment 1, so it is not repeated here, and this embodiment mainly sets forth the difference of the processing method:

[0049] A method for processing PBX composite materials containing hard foreign matter, including the above-mentioned device, the specific steps are as follows:

[0050] Step 1: Clamping: Fix the tool handle 1 on the Z-axis ram, and screw the pre-assembled connection box 2, spindle jacket 3, electric spindle 4 and ball end milling cutter 5 to the tool handle 1 through the connection box 2 Above; the tool diameter of the ball-end milling cutter 5 is Φ12 mm; the number of cutting edges of the ball-end milling cutter 5 is 12, and the helix angle of the ball-end milling cutter 5 is 30°.

[0051] Step 2: Cutting: Start the electric spindle 4, so that the ball end milling cutter 5 rotates under the action of the electric spindle 4, and then start the CNC vertical lathe. On the one hand, the ball ...

Embodiment 3

[0053] The device adopted in this embodiment is the same as that of embodiment 1, so it is not repeated here, and this embodiment mainly sets forth the difference of the processing method:

[0054] A method for processing PBX composite materials containing hard foreign matter, including the above-mentioned device, the specific steps are as follows:

[0055] Step 1: Clamping: Fix the tool handle 1 on the Z-axis ram, and screw the pre-assembled connection box 2, spindle jacket 3, electric spindle 4 and ball end milling cutter 5 to the tool handle 1 through the connection box 2 Above; the tool diameter of the ball-end milling cutter 5 is Φ16 mm; the number of blades of the ball-end milling cutter 5 is 11, and the helix angle of the ball-end milling cutter 5 is 30°.

[0056] Step 2: Cutting: Start the electric spindle 4, so that the ball end milling cutter 5 rotates under the action of the electric spindle 4, and then start the CNC vertical lathe. On the one hand, the ball end mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com