Secondary ejection mechanism and mold adopting same

A secondary ejection and mold technology, which is applied in the field of molds, can solve the problems of complex overall structure of the secondary ejection mechanism, poor integrity of the secondary ejection mechanism, and high processing and production costs, and achieve a simple and convenient secondary ejection structure. The effect of implementing and reducing processing and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

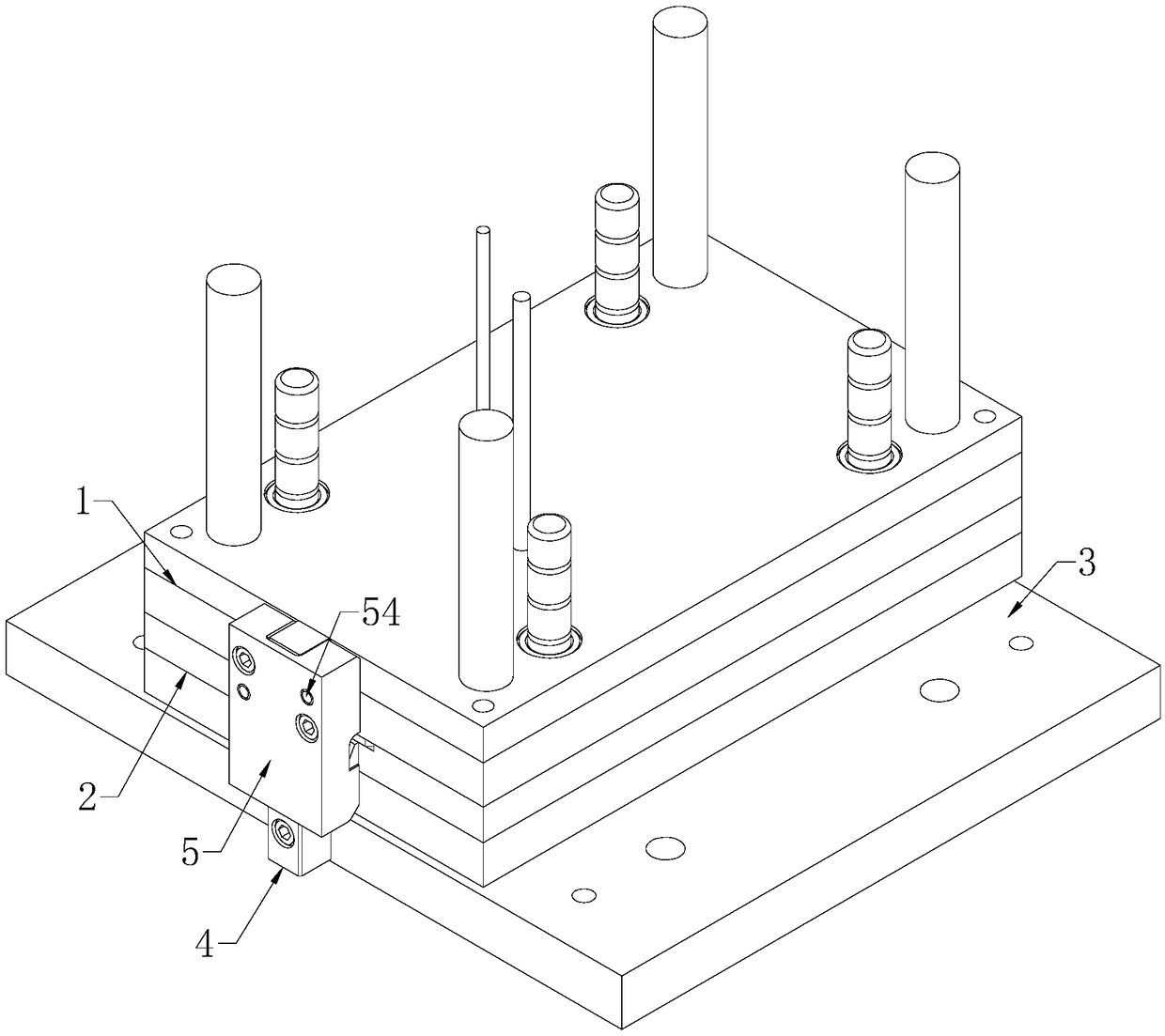

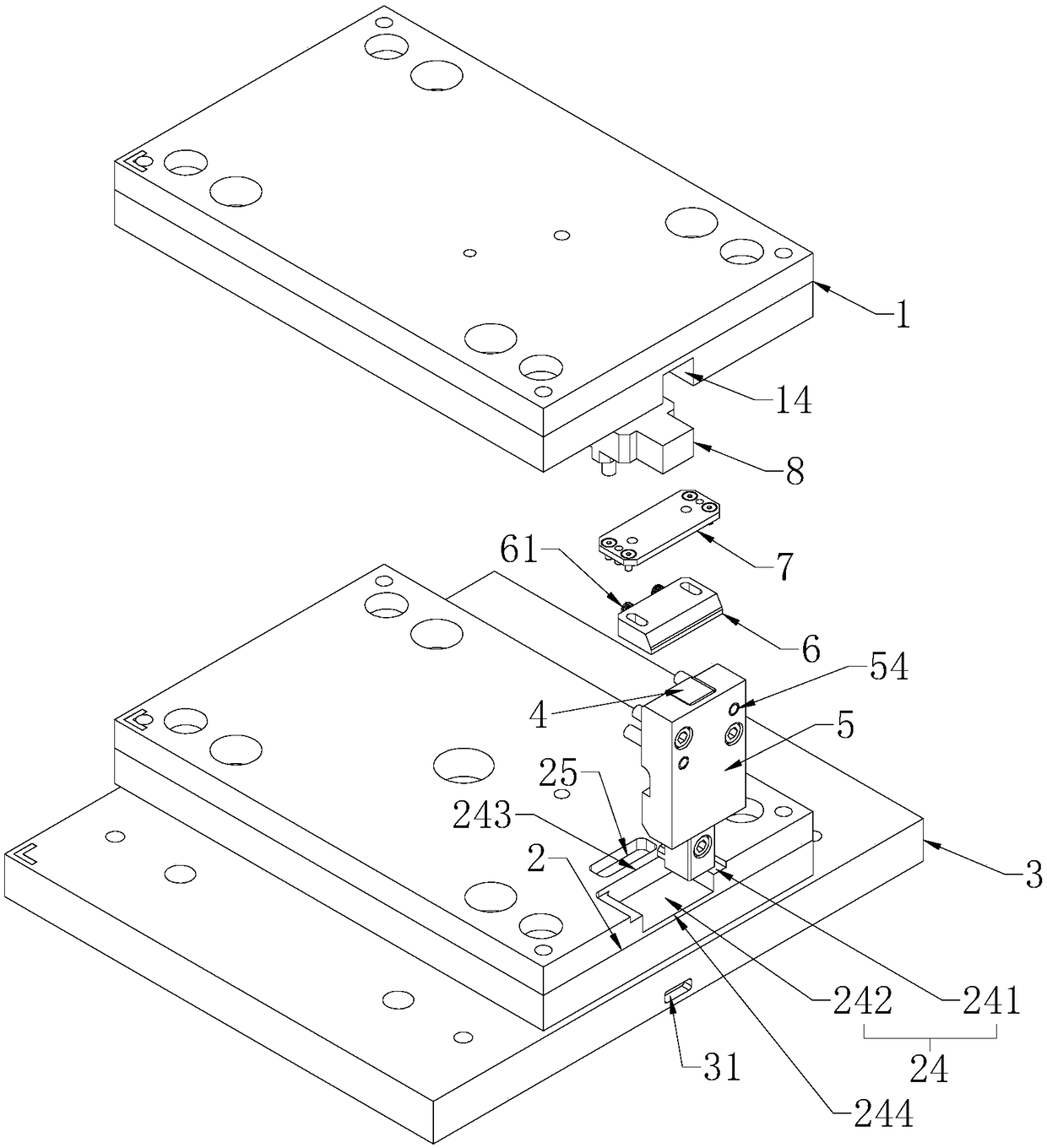

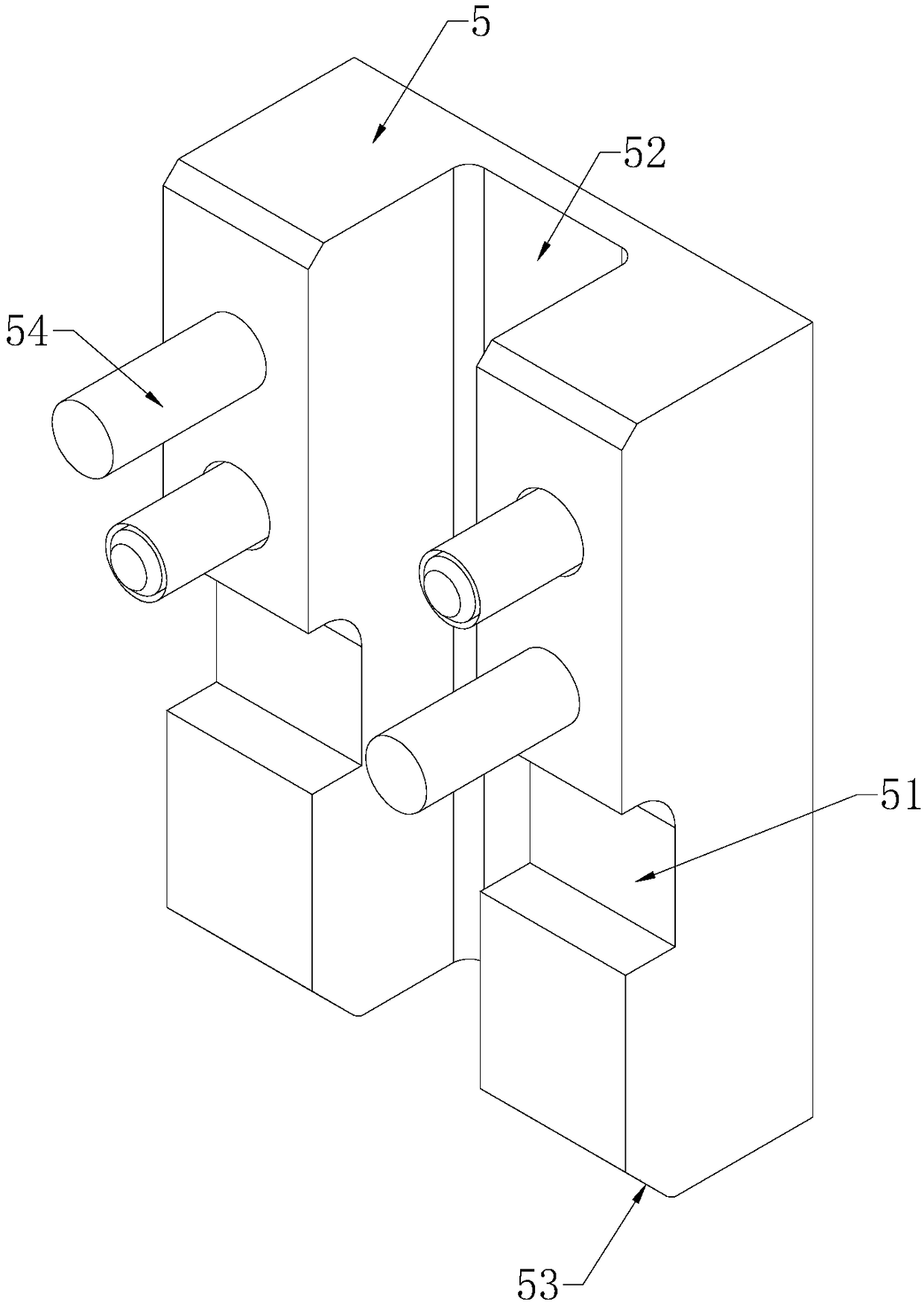

[0044] combine figure 1 and figure 2 As shown, a secondary ejection mechanism includes a guide rod 4 vertically attached to the side of the ejector plate, the bottom end of the guide rod 4 is fixed on the mold bottom plate 3 by screws, and the guide rod 4 slides vertically The shifting sleeve is provided with a fixed cover plate 5, and the fixed cover plate 5 is connected with the upper thimble plate 1 by screws. The lower ejector plate 2 is horizontally provided with a sliding block 6 and an elastic member 61 for driving the sliding block 6 to protrude from the lower ejector plate 2 , and the sliding block 6 partially extends out of the lower ejector plate 2 under the action of the elastic member 61 . On the fixed cover plate 5 and the guide rod 4, limit grooves 51 are respectively offered (referring to image 3 shown) and sliding groove 41 (see Figure 4 shown), and the elastic member 61 drives the sliding block 6 to protrude into the sliding groove 41 and at the same ti...

Embodiment 2

[0055] combine Figure 8 and Figure 9 As shown, a mold includes an upper mold 1A and a lower mold 1B, the top surface of the upper mold 1A and the bottom of the lower mold 1B are provided with a mold base plate 3, and the lower mold 1B and the corresponding mold base plate 3 are arranged There is the secondary ejection mechanism in the first embodiment. The upper ejector plate 1 includes a first ejector plate 11 and a second ejector plate 12 arranged horizontally, and the lower ejector plate 2 includes a third ejector plate 21 and a fourth ejector plate 22 arranged horizontally, and the receiving groove 24 Open at the upper surface of the third ejector plate 21 (combined figure 2 and Figure 9 shown), the mounting groove 14 is opened on the lower surface of the second ejector plate 12 (combined with figure 2 and Figure 9 shown). The four thimble plates are attached to each other in the initial state and can slide vertically along the guide column, and the first thimb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com