A standardized range-extended power system and management method

A power system and standard technology, applied in the field of new energy electric vehicles, can solve the problems of electrical interface and communication protocol mismatch, difficult to match each other, etc., to achieve high commercial value, reduce production costs, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

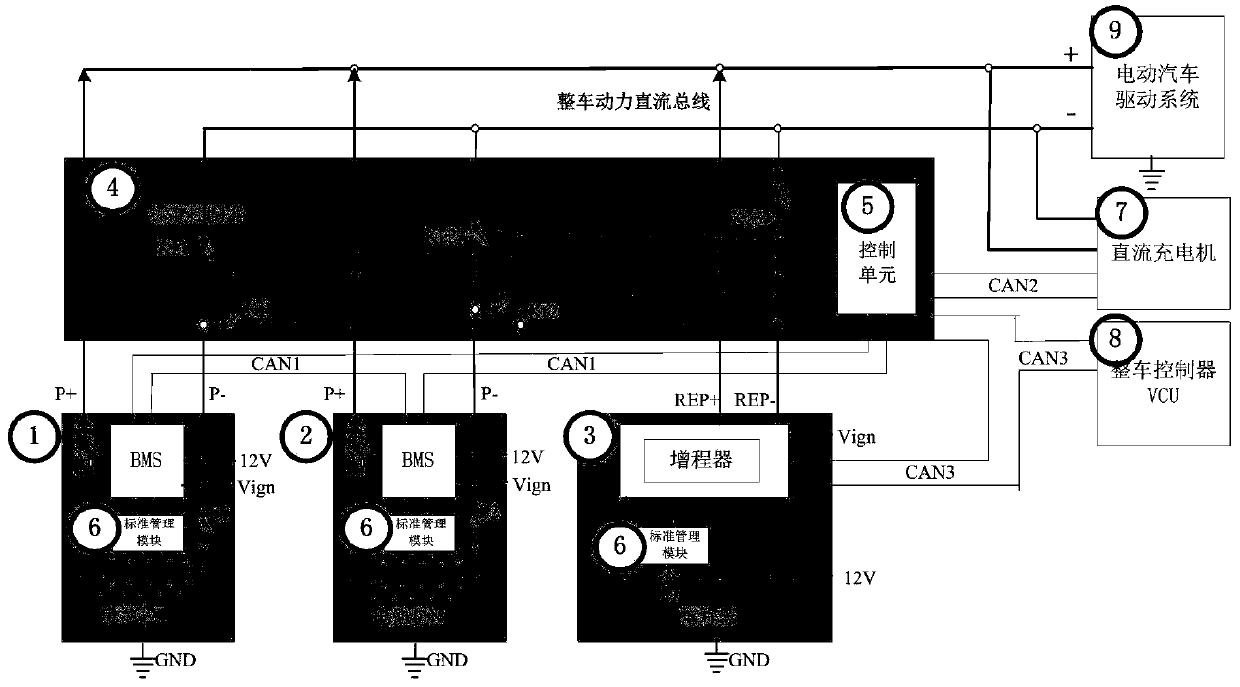

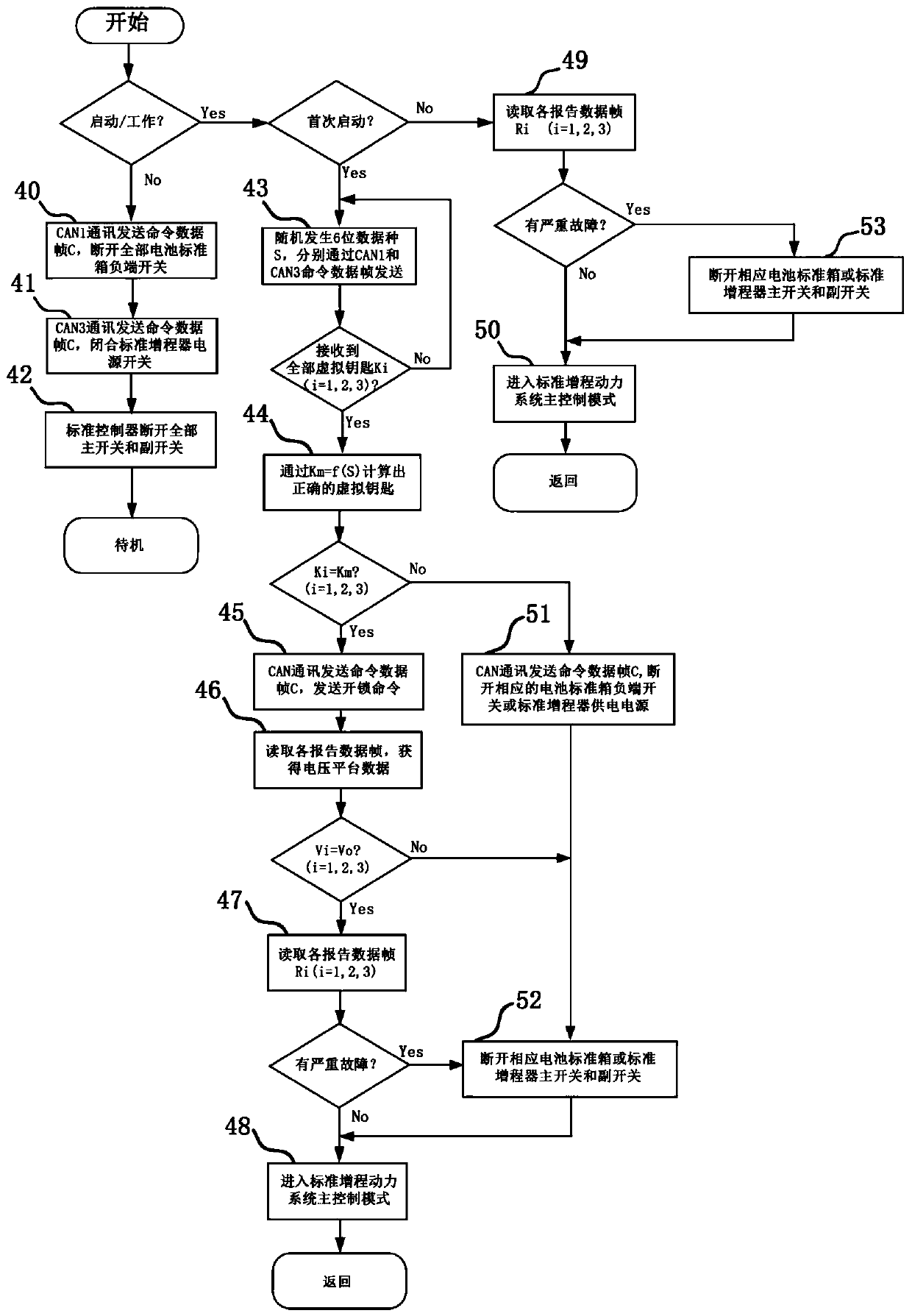

[0045] The present invention proposes a standardized range-extending power system, figure 1 It is a structural schematic diagram of the standardized range-extending power system. The control unit 5 in the standard controller 4 is responsible for the compatibility management of the battery standard box 1, the battery standard box 2 and the standard range extender 3 in the system, and simultaneously controls the battery standard box 1, the battery standard box 2 and the standard range extender 3. The connection between the main switches Kz1, Kz2 and Kz3 and the vehicle power DC bus; or through the auxiliary switches Kf1 and Kf2 to connect the standard range extender and the battery standard box.

[0046] The control unit 5 in the standard controller 4 communicates directly with the DC charger 7 through the CAN2 communication to coordinate the maximum allowable charging current and the start and end of charging; through the CAN3, the vehicle controller 8 and the standard range ex...

Embodiment 2

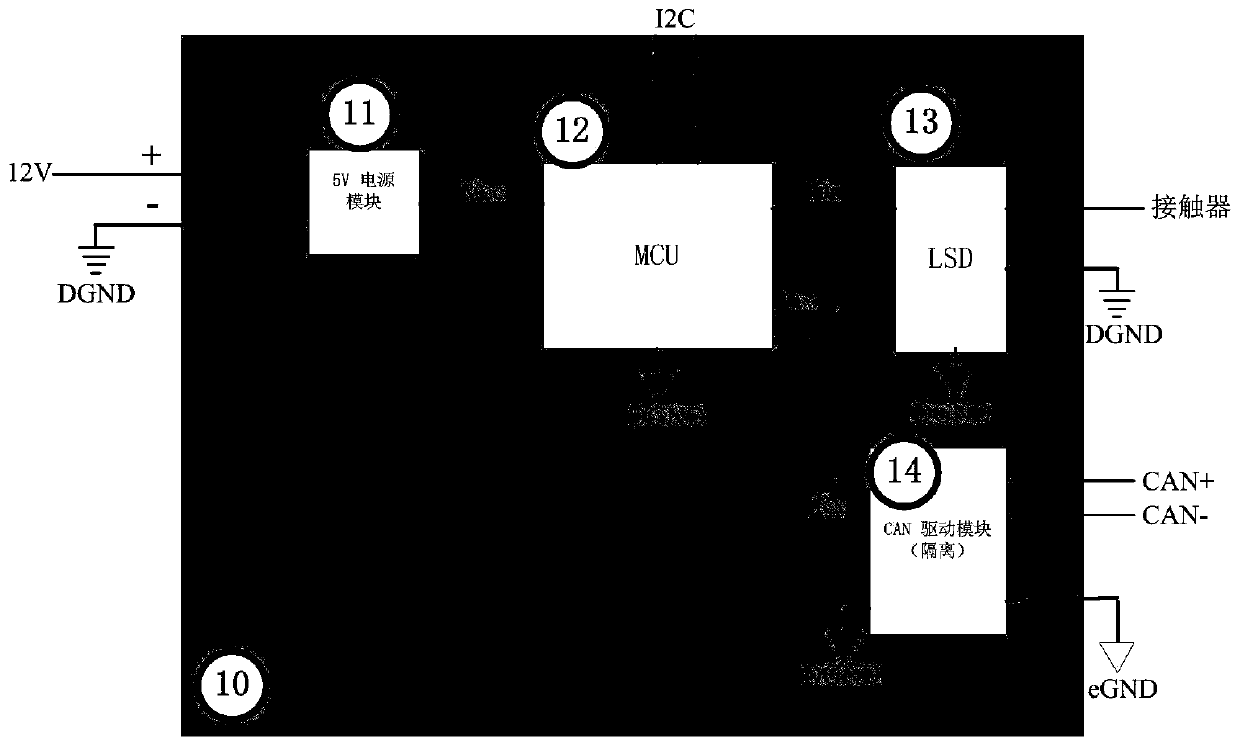

[0061] Compared with the above-mentioned embodiment, this embodiment provides the internal circuit structure of the standard management module 6, see figure 2. The standard management module 6 is a programmable IC chip or module 10, including a microprocessor MCU12 responsible for communication management and implementation control, a CAN driver module 14 responsible for CAN communication, a low-end control module LSD13 for switch control, and a 5V power supply module 11 Provides independent power supply for the standard management module 6. The CAN driver module 14 isolates the internal Tx / Rx communication from the external CAN+ / CAN- communication line, allowing the ground of the CAN communication signal to float.

[0062] The standard management module 6 of this embodiment exchanges status data with the battery management BMS and the standard range extender 3 through I2C serial communication, including the rated voltage values V of battery standard boxes 1 and 2 0 , err...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com