Cart with power drive

A power-driven, trolley technology, which is applied in the field of trolleys, can solve the problems of large physical strength consumption, large physical strength consumption of construction personnel, blocked vision, etc., and achieves the effect of simple structure, improved efficiency, and reduced physical strength consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

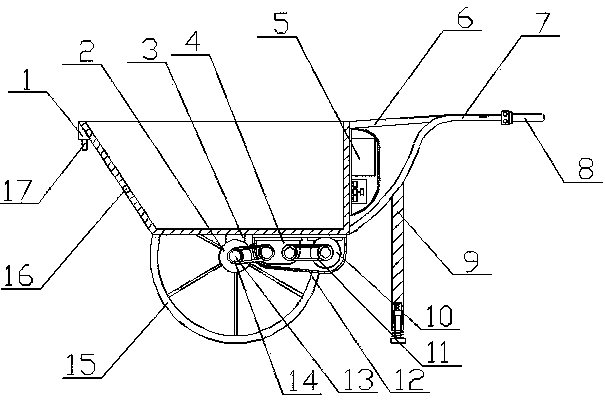

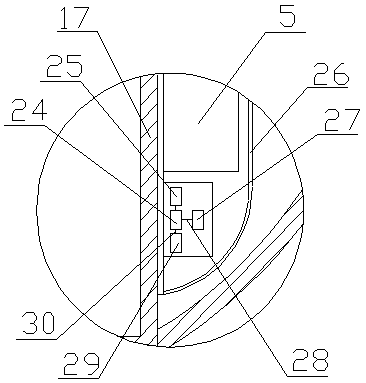

[0033] The power-driven trolley of the present invention is realized as follows: The power-driven trolley of the present invention includes a body body, a moving part, a driving part, a battery (5) and a control switch (22), and the bottom of the body body is arranged There are moving parts, the bottom of the body body is provided with a driving part that provides power for the moving parts, the body is provided with a battery (5) that provides power for the driving parts, and the body is provided with a control driving part to start and stop The control switch (22);

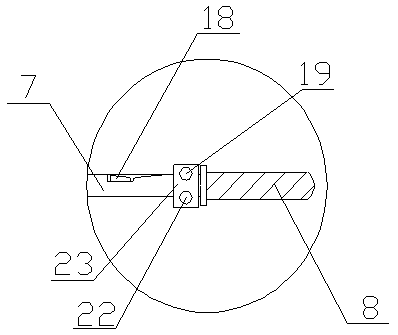

[0034] The main body of the vehicle body is composed of a reinforcing rod (6), a push handle (7), a support frame (9), a carriage (16) and a fixed plate (23). The push handle (7) is placed on one side of the carriage (16), so A reinforcing rod (6) is placed between the push handle (7) and one side of the carriage, a fixing plate (23) is placed on one end of the push handle (7), and an installation control switch ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com