Feeding device and production system

A feeding device and material technology, applied in the field of mechanical equipment, to achieve the effect of meeting the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

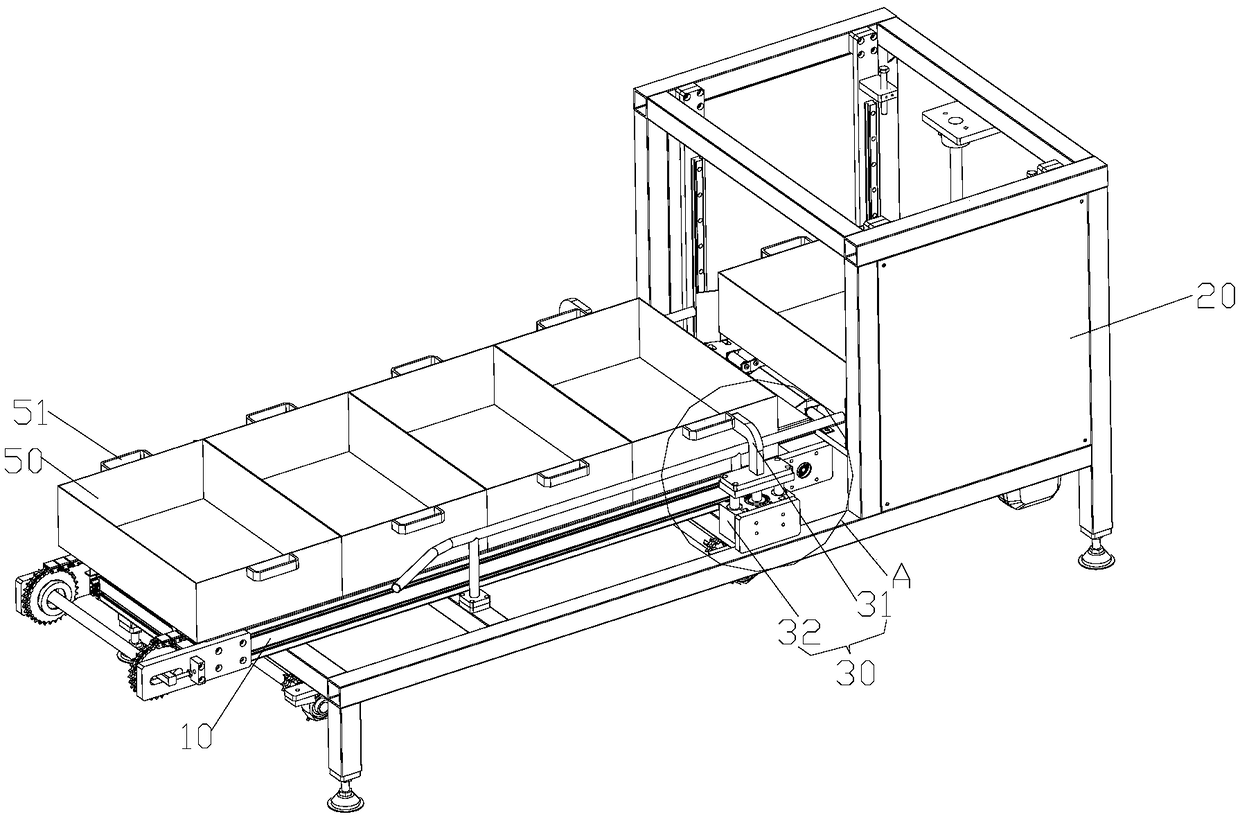

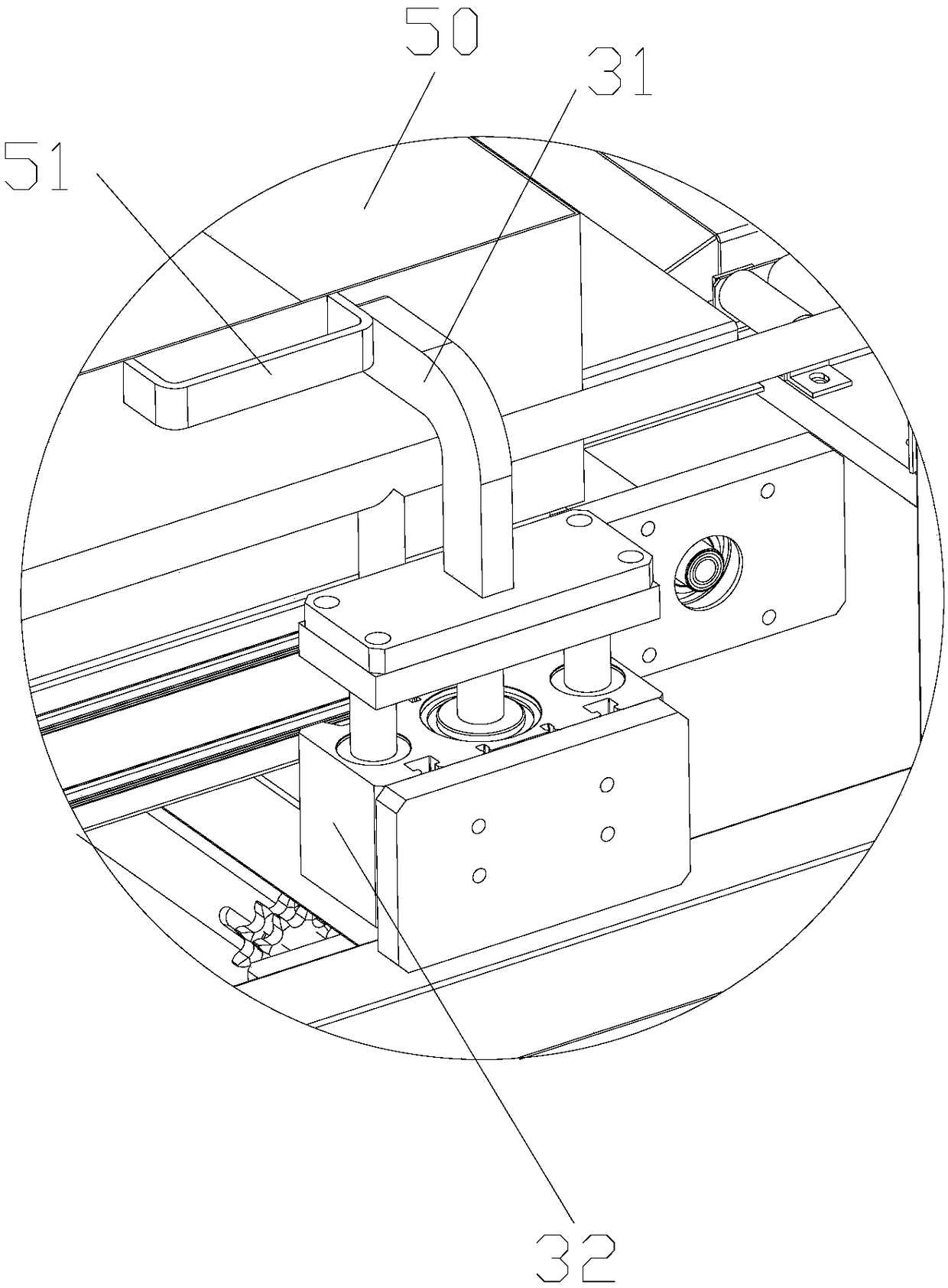

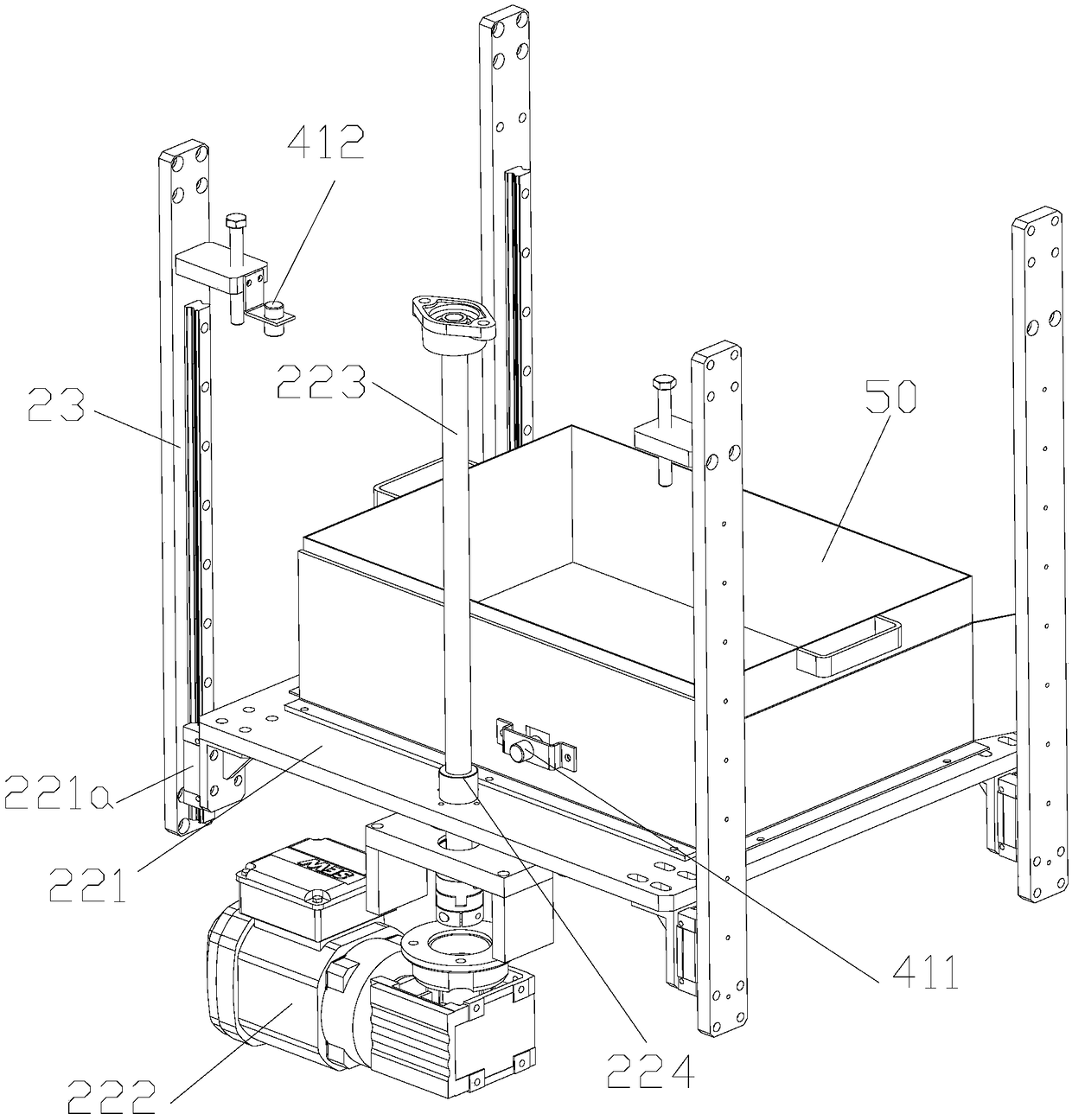

[0023] Such as Figure 1 to Figure 3 As shown, according to the embodiment of the present invention, the feeding device includes a first conveying part 10, a second conveying part 20, and a stopper 30, and the first conveying part 10 carries out horizontal conveyance of materials; the stopper 30 is connected with the first conveying part The stopper 30 has an open state that allows the material to enter the second conveying part 20 and a closed state that prevents the material from entering the second conveying part 20; The materials in the second conveying part 20 are lifted to the feeding position.

[0024] The cooperation between the first conveying part 10 and the second conveying part 20 of the feeding device can transport the material from the material preparation position to the material supply position for the production staff to take. The stoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com