A kind of industrial production method of bis(2,6-di-tert-butyl-4-methylphenyl)pentaerythritol phosphite

A technology for pentaerythritol phosphite and pentaerythritol dichlorodiphosphite, which is applied in the field of organic chemical preparation, can solve the problems of difficulty in catalyst separation and recovery, unsuitable for industrial production, easy to cause pollution to the environment, and the like, and achieves high production efficiency , the effect of shortening the reaction cycle and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

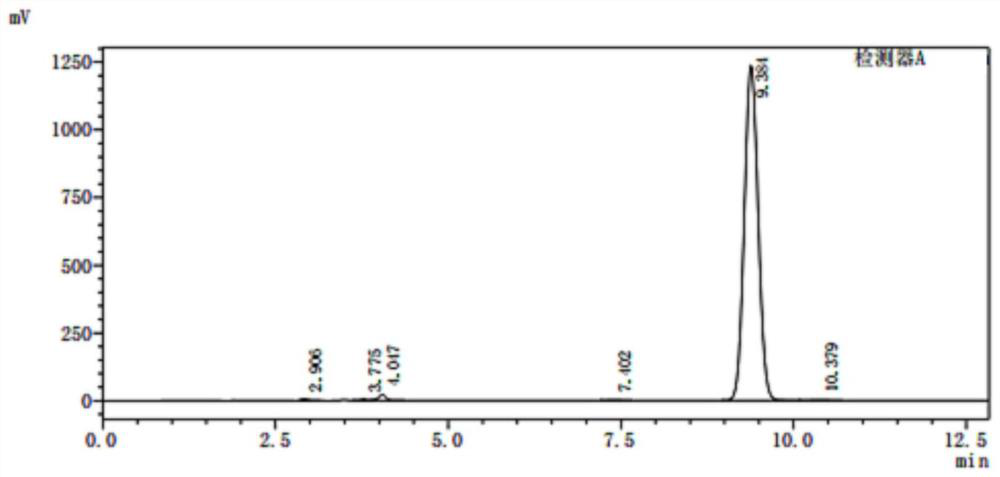

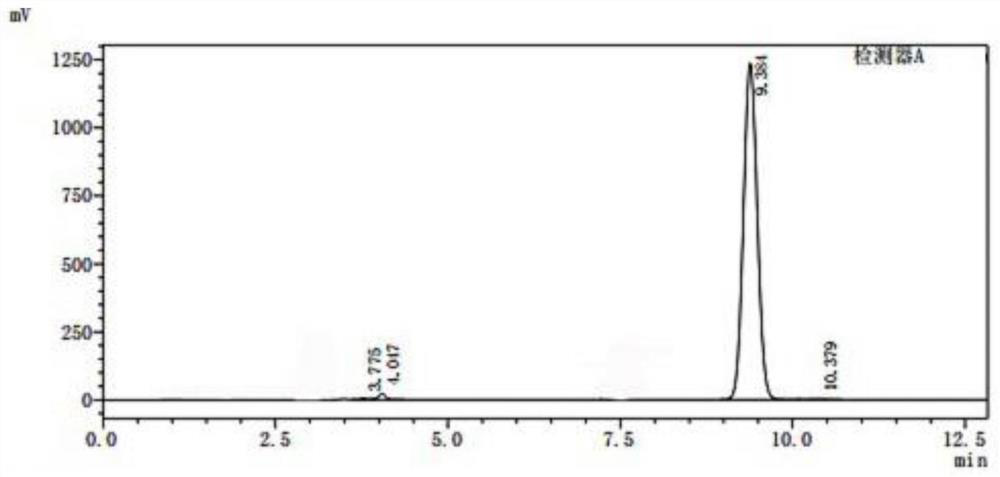

[0045] as per figure 1 The production process flow chart shown carries out the production preparation of bis(2,6-di-tert-butyl-4-methylphenyl) pentaerythritol phosphite (PEP-36), and the steps are as follows:

[0046] (1) Preparation of 2,6-di-tert-butyl-4-methylphenol sodium salt: add 2,6-di-tert-butyl-4-methylphenol and Sodium methoxide, while adding toluene in the primary reaction kettle 2 through the solvent pipeline 3, open the agitator 4, the reaction temperature is 60 ° C, and pass through the N 2 The booster pump 5 makes the pressure in the primary reactor 2 be 200kpa, and the reaction time is 2h, and the mol ratio of the 2,6-di-tert-butyl-4-methylphenol and sodium methylate is 1:1.2, after the reaction finishes , cooled to 20°C, suction filtered in filter 6, and washed twice with toluene to obtain 2,6-di-tert-butyl-4-methylphenol sodium salt;

[0047] (2) Preparation of dichlorodiphosphite pentaerythritol ester solution: add pentaerythritol in the secondary reactor ...

Embodiment 2

[0053] as per figure 1 The production process flow chart shown carries out the production preparation of bis(2,6-di-tert-butyl-4-methylphenyl) pentaerythritol phosphite (PEP-36), and the steps are as follows:

[0054] (1) Preparation of 2,6-di-tert-butyl-4-methylphenol sodium salt: add 2,6-di-tert-butyl-4-methylphenol and Sodium methylate, add xylene in the primary reactor 2 through solvent line 3 simultaneously, open agitator 4, reaction temperature is 80 ℃, pass N 2 The booster pump 5 controls the internal pressure of the primary reactor 2 to be 400kpa, and the reaction time is 1.5h. The mol ratio of the 2,6-di-tert-butyl-4-methylphenol and sodium methylate is 1:1.4, and the reaction ends Afterwards, the temperature was lowered to 50°C, suction filtration was performed in the filter 6, and rinsed twice with xylene to obtain 2,6-di-tert-butyl-4-methylphenol sodium salt;

[0055](2) Preparation of dichlorodiphosphite pentaerythritol ester solution: add pentaerythritol in sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com