Washing machine with defoaming device

A washing machine and foam technology, applied in the field of washing machines with a de-foaming device, can solve the problems affecting the performance and user experience of the washing machine, waste of detergent and water resources, foam overflow, etc., to save water resources and detergent, and eliminate foam. ,Easy to install and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

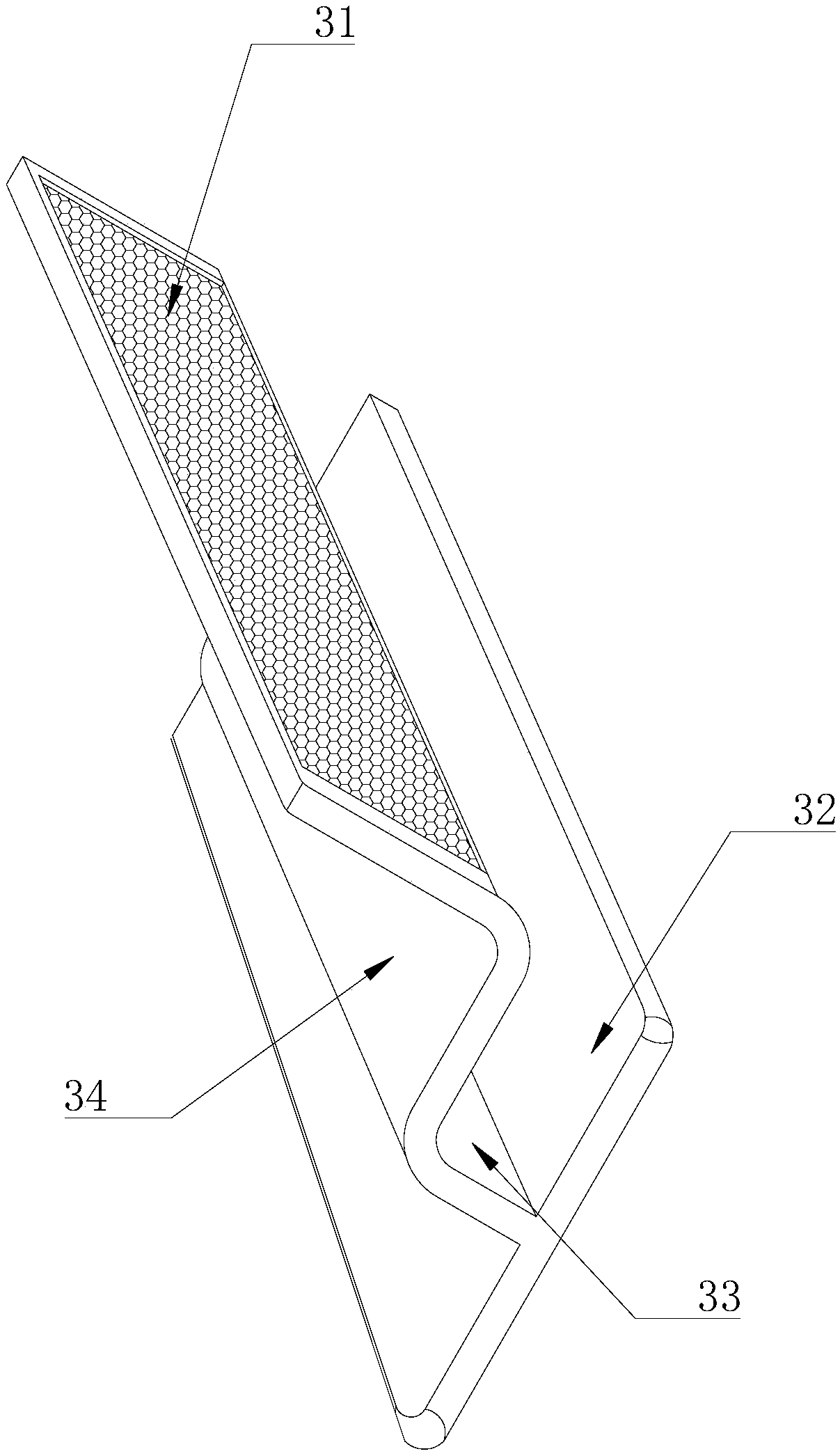

[0042] Such as image 3 As shown, the filter screen 3 described in this embodiment is arranged between the inner cylinder 2 and the outer cylinder 1, the filter screen 3 can eliminate the foam between the inner cylinder 2 and the outer cylinder 1, and save water resources and waste of washing water .

[0043] In this embodiment, the filter screen 3 is a sheet-like structure, and the sheet-like structure is parallel to the axis of the inner cylinder 2, increasing the contact area between the filter screen 3 and the foam, effectively eliminating foam, and the sheet-like structure and the radial direction of the inner cylinder 2 have An angle of inclination, preferably, the filter screen 3 is inclined from the side of the outer cylinder 1 to the side of the inner cylinder 2, and to the side opposite to the rotation direction of the inner cylinder 2.

[0044] In this embodiment, the sheet structure is perpendicular to the radial direction of the inner tube 2 .

[0045] In the pr...

Embodiment 2

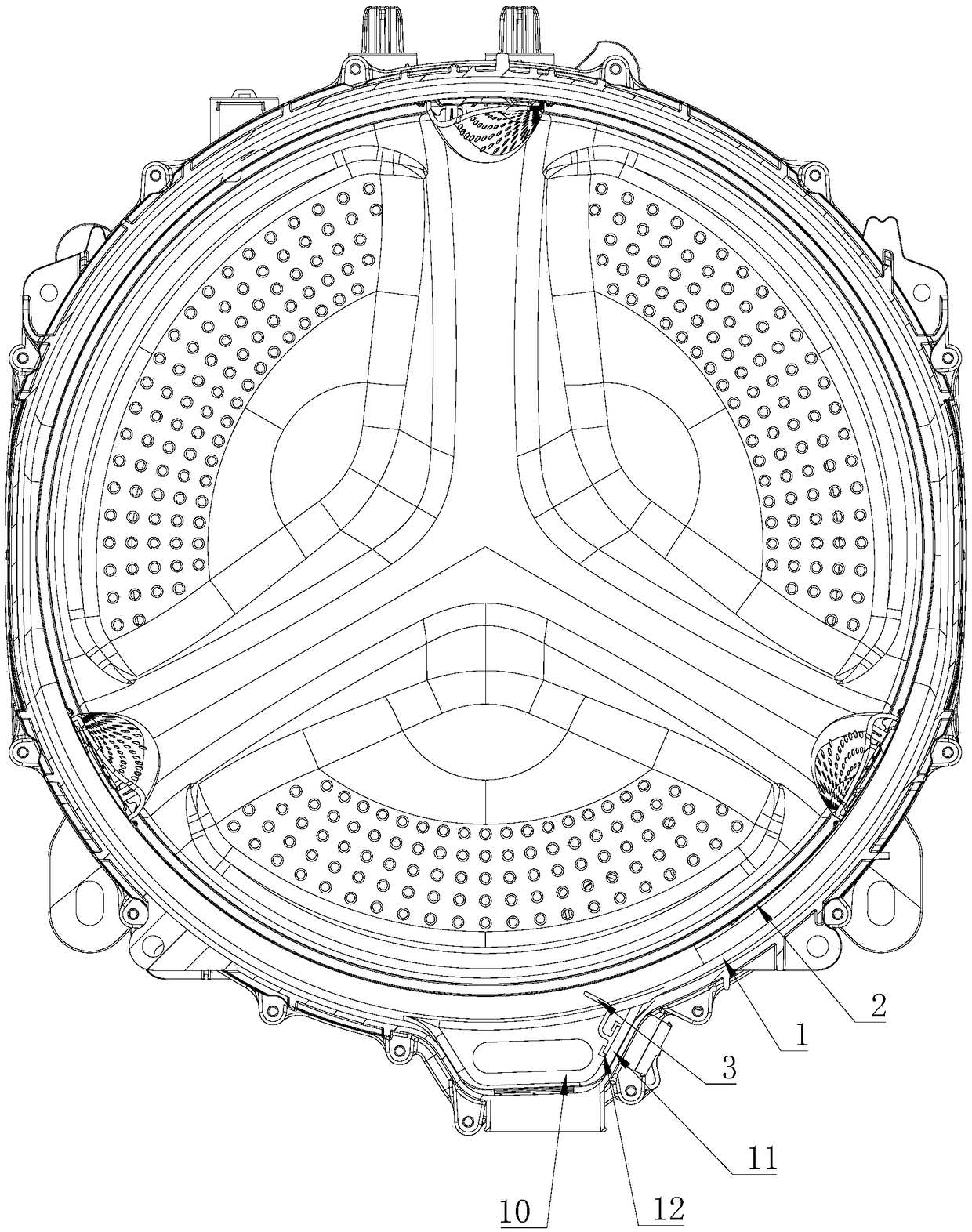

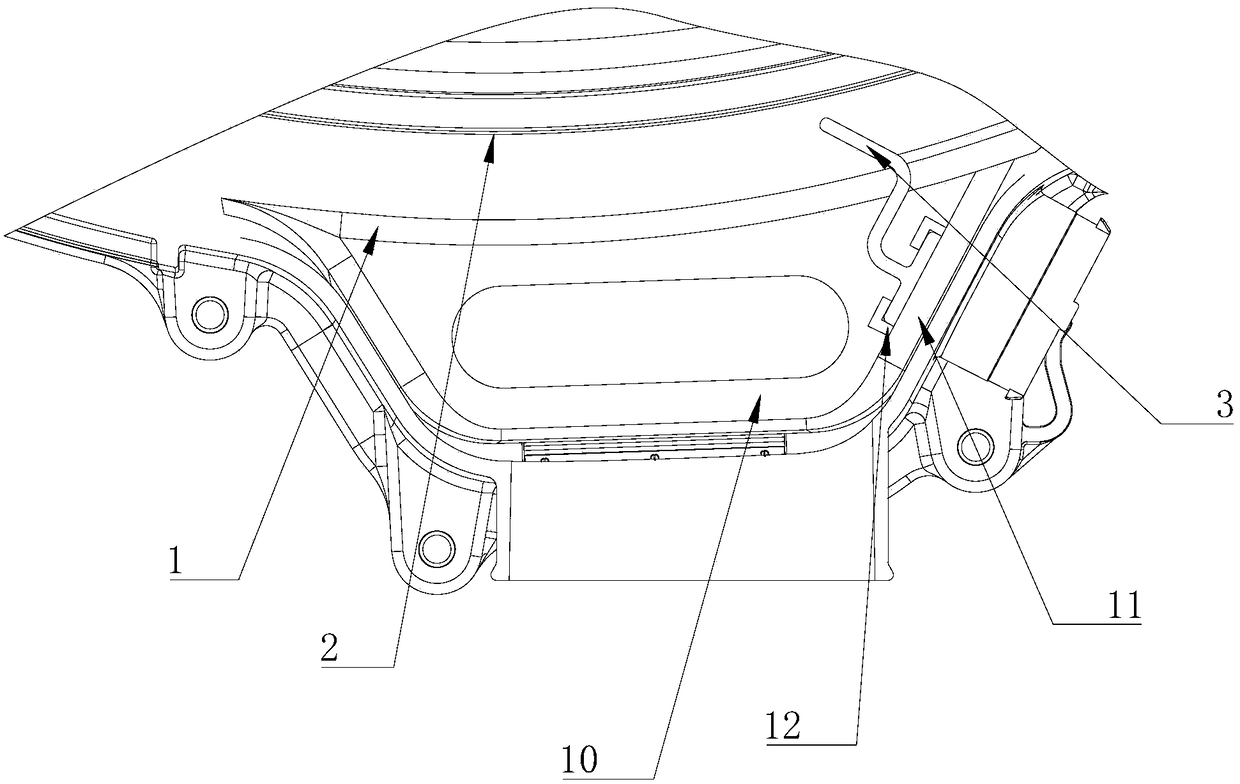

[0053] Such as figure 1 and figure 2 As shown, a washing machine with a foam removing device described in this embodiment includes an outer cylinder 1 and a rotatable inner cylinder 2 set inside the outer cylinder 1. The drain groove 10 is sunken outside, and the filter screen 3 protruding and extending toward the inner cylinder 2 is installed on the side wall 11 of the drain groove 10 .

[0054] In this embodiment, the inner wall of the outer cylinder 1 is provided with an outwardly recessed drainage groove 10, the drainage groove 10 opens toward the side of the inner cylinder 2, the side wall 11 of the drainage groove 10 is inclined from the bottom wall to the opening, and the slot 12 is provided On the side wall 11 of the drain tank 10, the fixed part 32 of the filter screen 3 is fitted and fixed with the side wall 11 of the drain tank 10; The end of the net 3 extends obliquely toward the drainage groove 10, and the filter mesh 3 extends toward the inner cylinder 2 to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com