Intelligent Identification and Constraint System of Roof Deformation

A technology of intelligent identification and restraint system, which is applied in the direction of scaffolding supported by housing structure, housing structure support, housing structure support, etc., can solve the problem that the vertical deformation of the sliding unit is controlled within a reasonable range, and the sliding track cannot bear such a problem. Large, large vertical deformation and other problems, to achieve the effect of improving measurement accuracy and measurement efficiency, improving construction control accuracy and efficiency, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

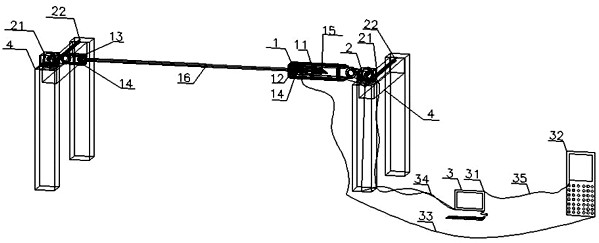

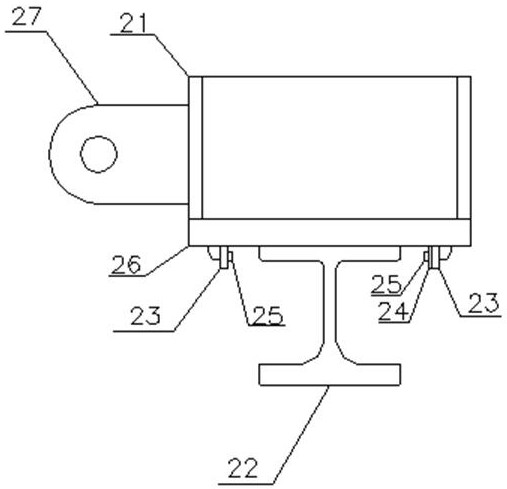

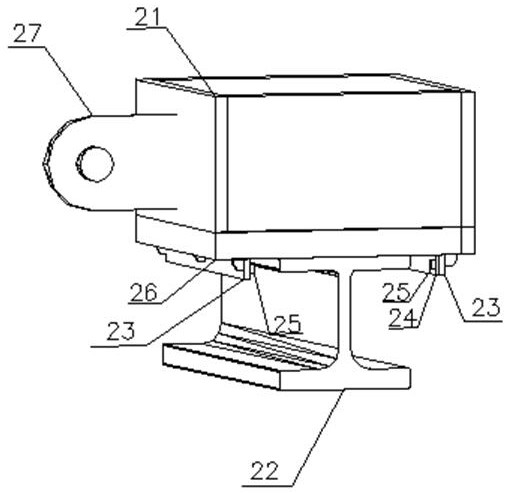

[0027] An intelligent recognition and restraint system for roof deformation during the sliding construction of long-span arched shell roofs, including prestress loading subsystem 1, sliding shoe horizontal displacement recognition and restraint subsystem 2, and computer acquisition and control subsystem 3, such as Figure 1-3 As shown, the specific structure is:

[0028] The prestress loading system 1 is composed of the active end reaction frame 12, the passive end reaction frame 13, the hydraulic cylinder 11 and the steel strand 16. It is characterized in that the reaction frame is used in pairs, and the reaction frame includes the active end reaction frame 12 and The reaction force frame 13 at the passive end, the reaction force frame 12 at the active end is consistent with the reaction force frame 13 at the passive end, the geometric scale of the reaction force frame 13 at the passive end is slightly smaller than the reaction force frame 12 at the active end, the reaction f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com