Clamping forceps with swingable jaws

A clamping pliers, swinging technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of poor clamping effect, easy to wear, etc., to achieve a wide range of pipe diameters, ensure stability, improve The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

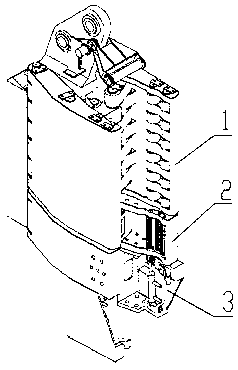

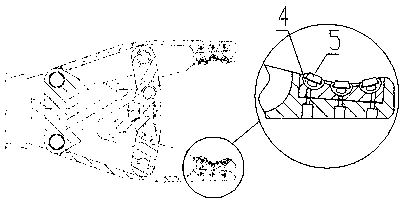

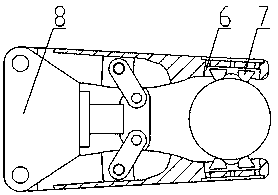

[0032] Such as Figure 1 to Figure 9 A swingable clamp with jaws shown includes a combined hydraulic cylinder 8, a left arm frame 9 and a right arm frame 10, and the tail ends of the left arm frame 9 and the right arm frame 10 are hinged on the combined hydraulic cylinder 8 Above, the middle parts of the left arm frame 9 and the right arm frame 10 are hinged with the clamp driving piston rod of the combined hydraulic cylinder 8 through the connecting rod 16, and the jaws are installed in the grooves at the front ends of the left arm frame 9 and the right arm frame 10. Cage assembly, two sets of jaw assemblies 15 are respectively installed in the jaw cage assembly, each set of jaw assemblies 15 includes jaw holder 14 and jaw teeth 13, jaw holder 14 is a triangular column structure, and its triangular The tail part is hinged to the clamp teeth cage assembly th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com