Transmission structure of micro three-bearing vector spray tube and control method of transmission structure

A technology of vector nozzle and transmission structure, which is applied in the direction of machine/engine, jet propulsion device, etc., can solve the problems such as the inability to solve the problem of lightweight vector nozzle, increase the weight of axisymmetric vector nozzle, and reduce the safety of UAV. , to simplify the complex action of rotational deformation, avoid heavy weight, and achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

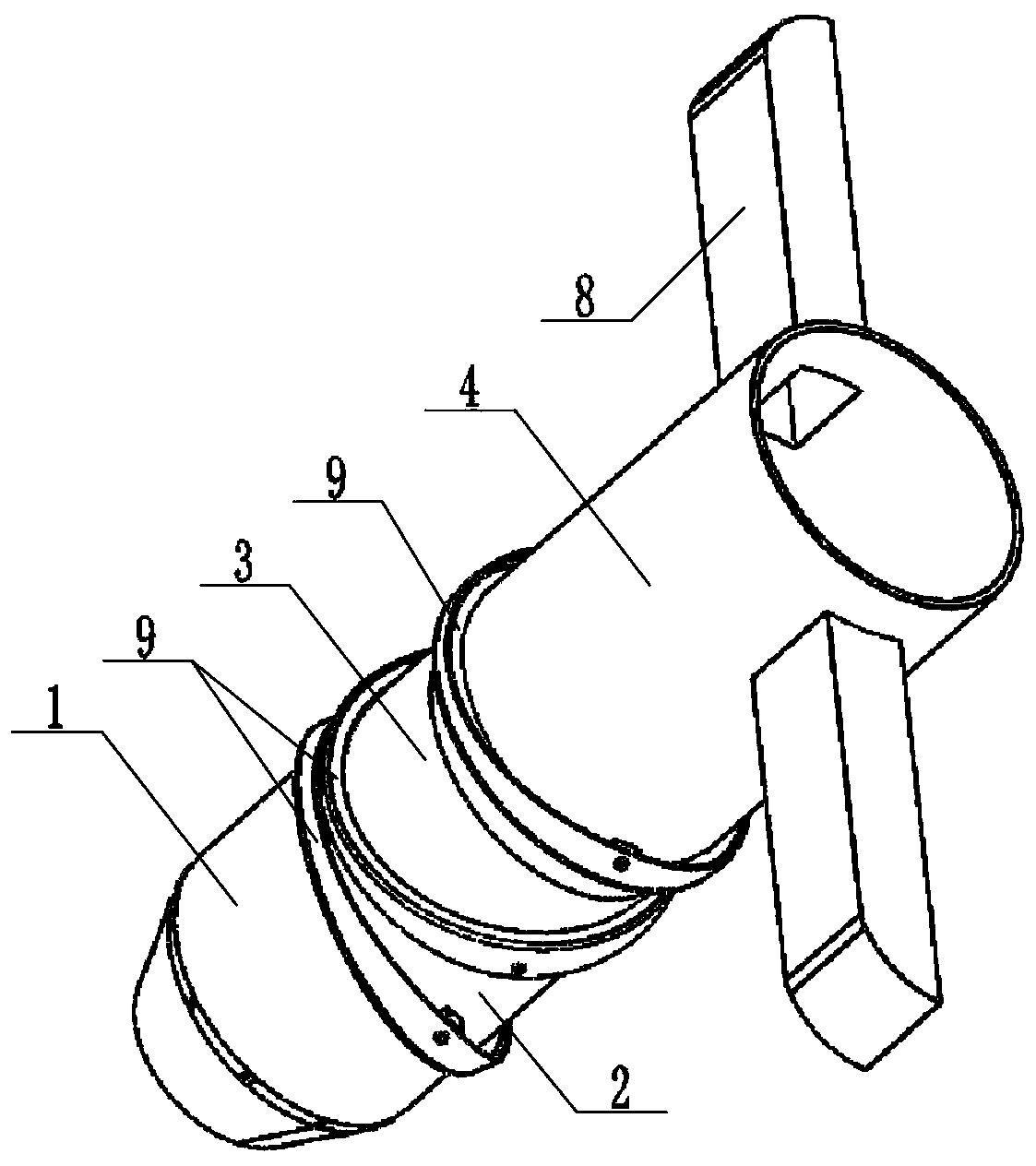

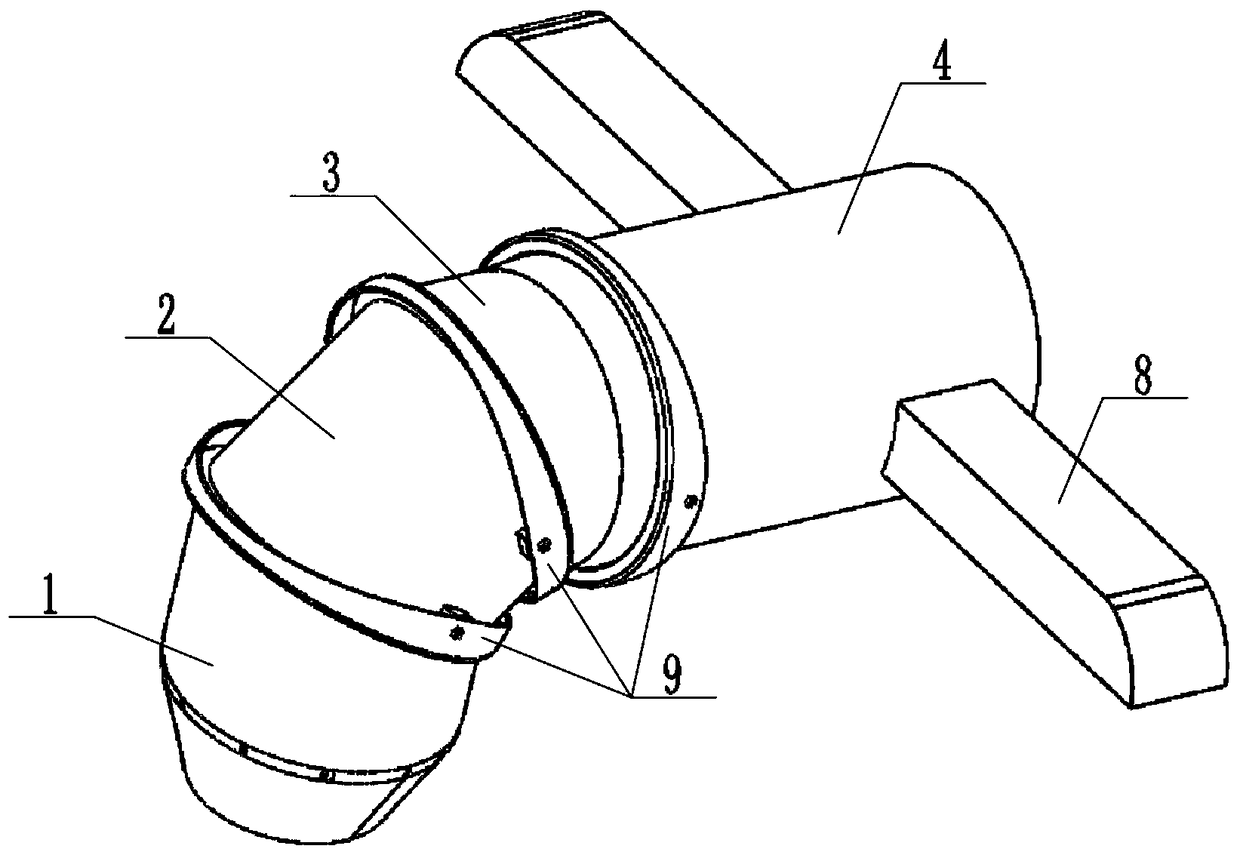

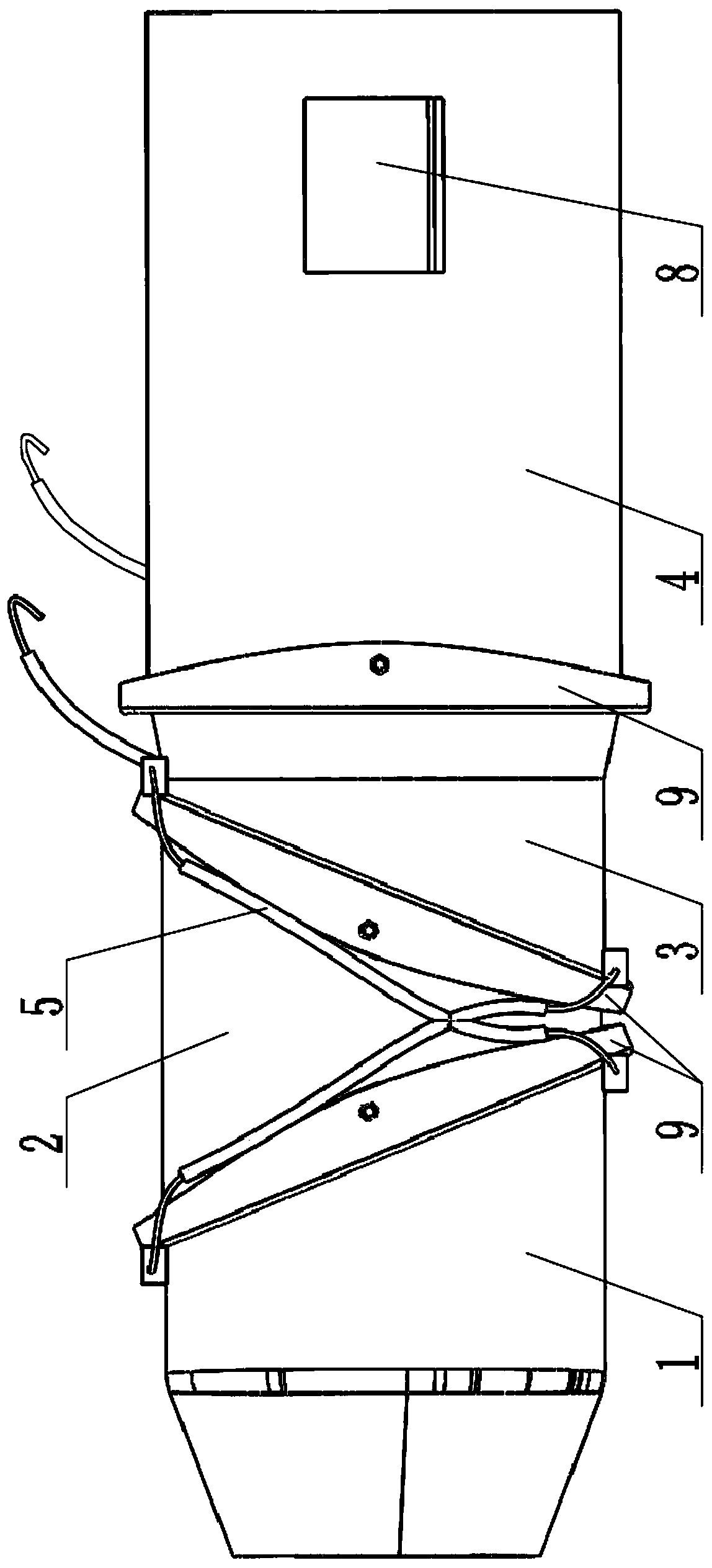

[0027] Below in conjunction with accompanying drawing, the present invention will be further described (hereinafter referred to as figure 1 The left direction of the left direction is the front for description, and the end of the obtuse angle between the inclined plane structure on the nozzle front section 1, the nozzle middle section 2 and the nozzle rear section 3 in the side view direction and the pipe wall is the top of the inclined plane structure For description, the bottom end of the slope structure is described with the end of the slope structure on the front section 1 of the nozzle, the middle section 2 of the nozzle, and the rear section 3 of the nozzle in the side view direction and the angle between the pipe wall and the pipe wall being an acute angle).

[0028] Such as Figure 1 to Figure 4 As shown, the transmission structure of the miniature three-bearing vector nozzle includes an axisymmetric vector nozzle and a vector nozzle traction control mechanism.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com