Backhoe type blade micro-lift pump device

A head pump and vane technology, which is applied to pump devices, parts of pumping devices for elastic fluids, non-variable pumps, etc., can solve the problem of unstable unit operation, low efficiency of pump devices, and low pressure on the suction surface of blades and other issues, to achieve the effect of urban pollution prevention and control, major economic benefits, and important academic significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

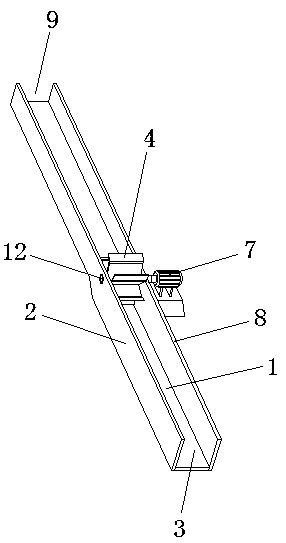

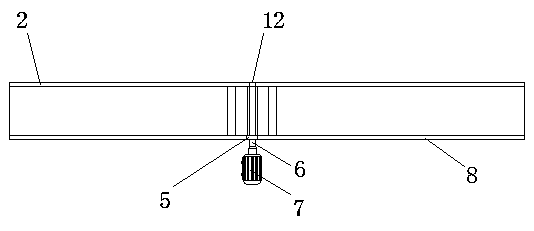

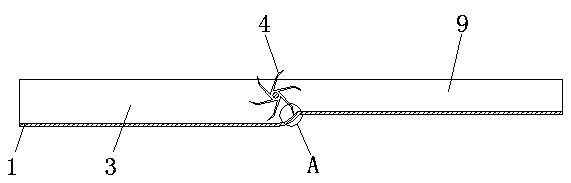

[0021] like Figure 1-5 As shown, a backhoe vane micro-lift pump device includes a motor 7 and a pump shaft 6 connected to the output shaft of the motor 7; the micro-lift pump device is also composed of a base plate 1, a left slot plate 2, a right slot plate 8 and an impeller 4 components; the left trough 2 and the right trough 8 are respectively fixed on the left and right sides of the bottom plate 1, and the left trough 2 and the right trough 8 respectively form a whole with the bottom plate 1. The front end is the water inlet 3 and the rear end is the water outlet 9. type water tank, the groove bottom surface of the water outlet groove 9 is higher than the groove bottom surface of the water inlet groove 3, and an arc transition connection is formed between the water outlet groove 9 and the water inlet groove 3, and the impeller 4 is arranged at the arc transition connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com