A five-station solid propellant normal high temperature stress relaxation test device and method

A solid propellant and stress relaxation technology, which is applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as stress relaxation comparison tests, improve test efficiency, and save test time and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

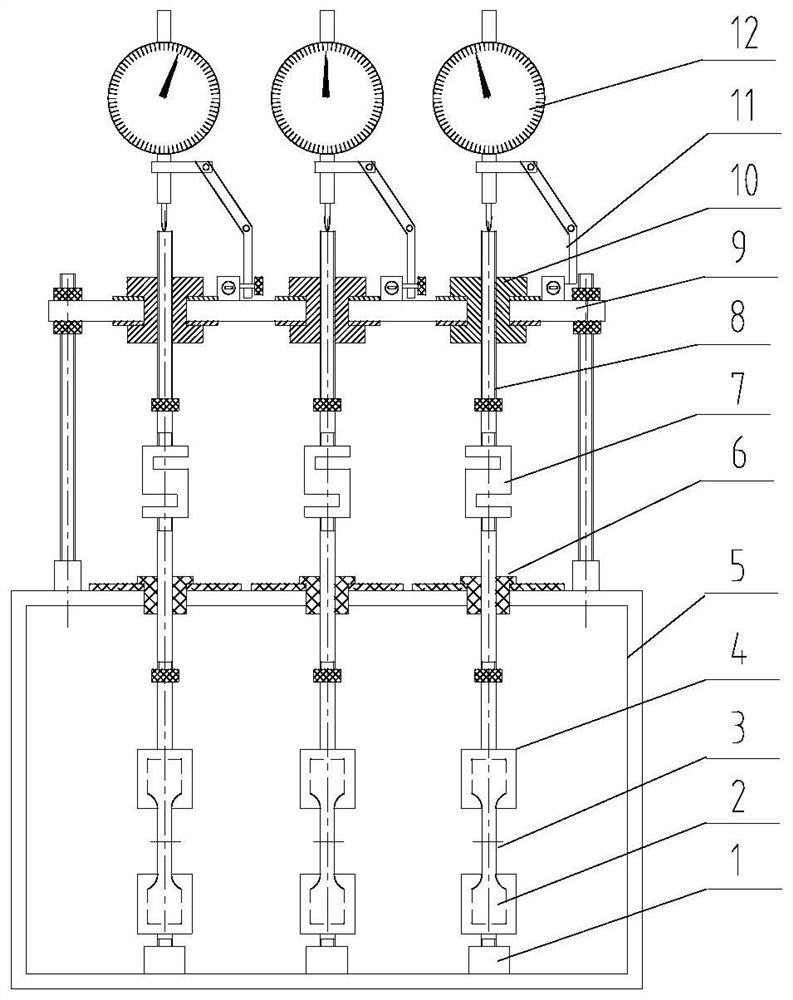

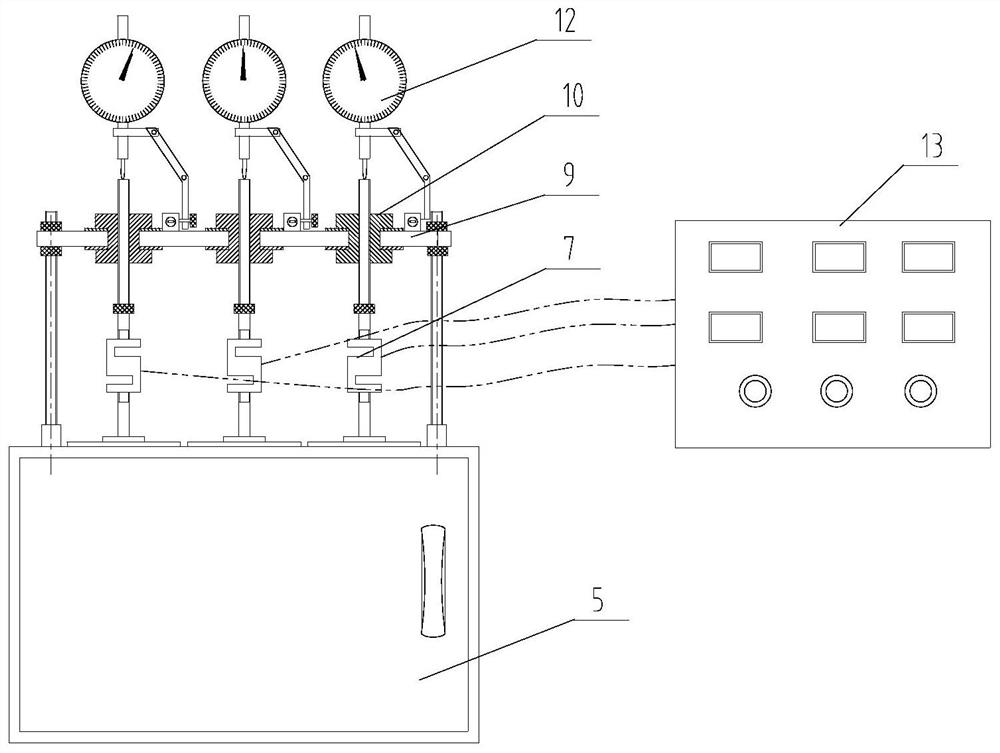

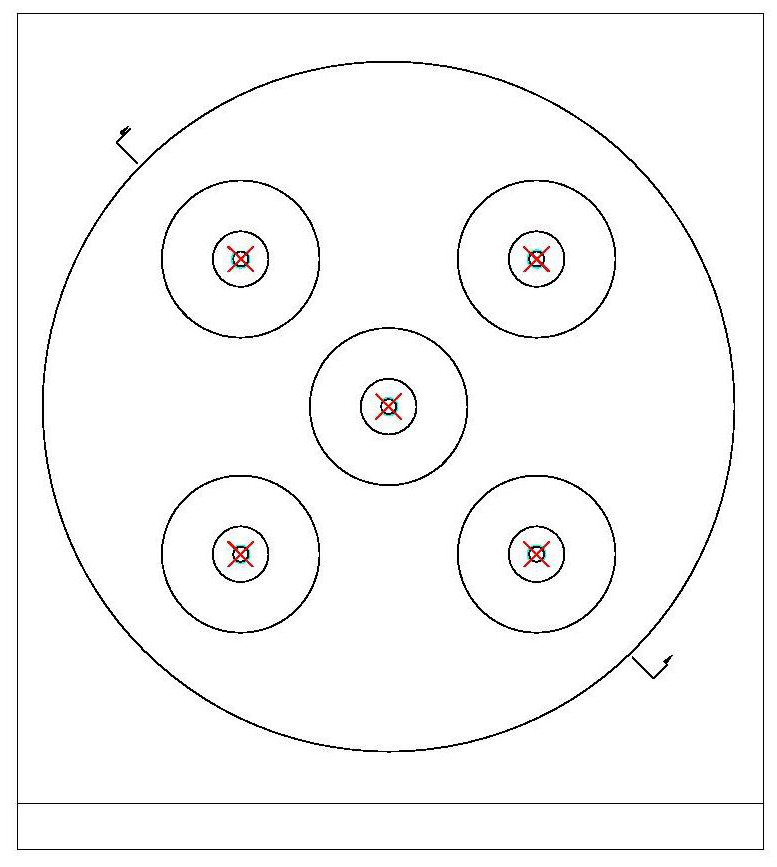

[0019] figure 1 and figure 2 It is a structural schematic diagram of a five-station solid propellant normal high temperature stress relaxation test device of the present invention. Such as figure 1 , figure 2 As shown, five bases 1 are provided at the bottom of the water-jacketed incubator 5, and five through holes 6 are provided at the top of the tank, the positions of the through holes 6 correspond to the base 1, and the lower clamping member 2 mounted on base 1. The upper clamping part 4 passes through the through hole 6 and is connected with the load sensor 7 , and the sample 3 is installed between the upper clamping part 4 and the lower clamping part 2 .

[0020] The carrying platform 9 is located at the upper part of the water-jacketed incubator 5 and is supported by four pillars. The deformation adjusting nut 10 is installed on the bearing platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com