Integral moving type annular wire winding machine

A mobile winding machine technology, applied in coil manufacturing, electrical components, inductance/transformer/magnet manufacturing, etc., can solve the problems of occupying a large production space and not being able to move freely, so as to avoid overlapping or crossing, occupying The effect of small floor area and reduced work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

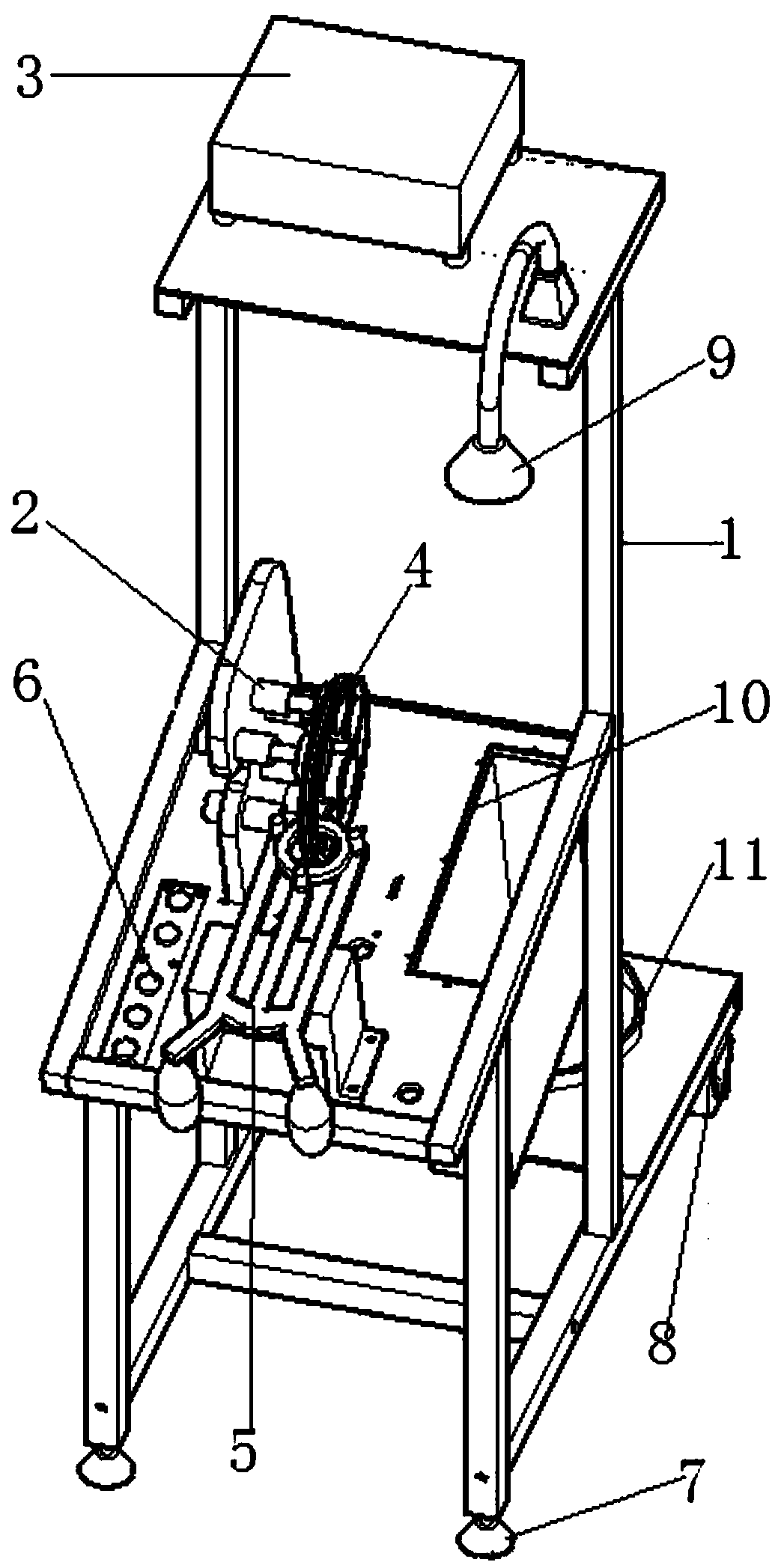

[0015] Such as figure 1 As shown, the present invention is an integral mobile ring winding machine, including a frame 1, a machine head 2, an electric control box 3, a transmission mechanism, a wire storage ring 4, and a magnetic core clamping mechanism 5. It is characterized in that the The frame is a three-layer vertical integral aluminum alloy frame, the upper layer of the frame is provided with an electric control box; On the driving roller, the driving roller of the driving roller is connected to the transmission mechanism, the magnetic core clamping mechanism is electrically connected to the transmission mechanism, the transmission mechanism is elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com