A lithium-ion battery core winding and stacking method

A lithium-ion battery and winding core technology, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of reducing the specific mass energy density of battery modules, and achieve specific mass energy density, reduce consumption, and roll core size Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

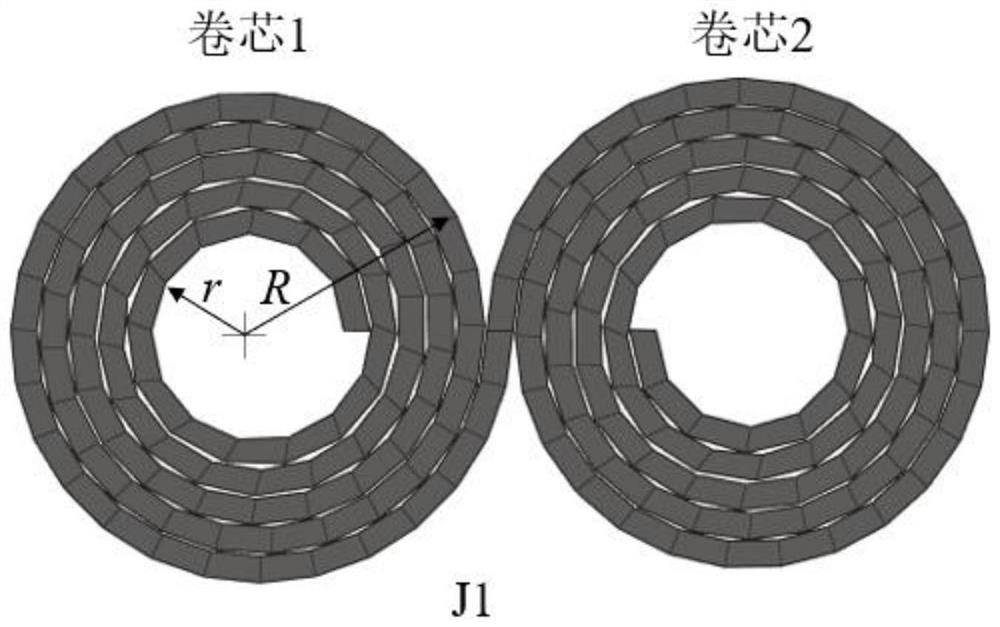

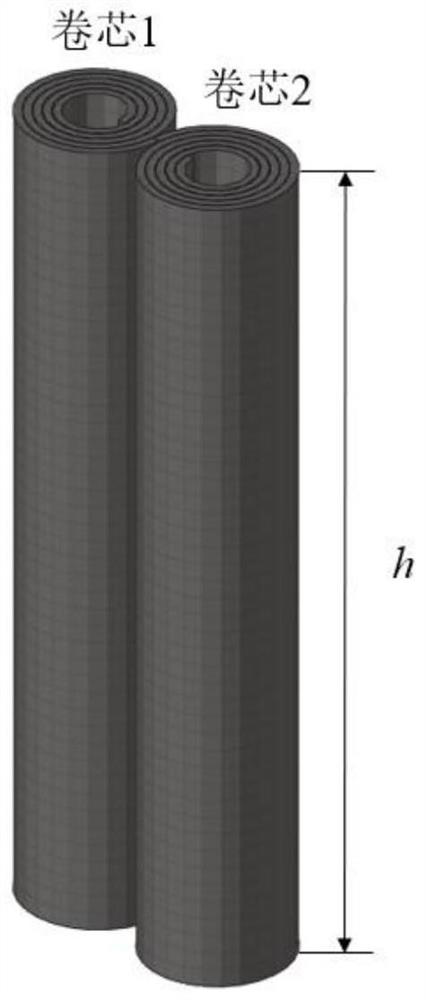

[0023]The present invention is based on the basic design idea that the winding mode of the winding core needs to be improved. At present, the winding mode at both ends of the winding core is very suitable. The two ends of the winding core of the present invention can be wound at the same time to reduce the size of a single winding core, and the increase in the number of winding cores can also reduce the current carried by each winding core during high-current discharge, thereby reducing the winding core's experience in use. damage. According to the size of the battery required, the winding diameter and length of the core, the number of cores in each layer and the number of layers stacked on the core are adjusted, and the overall size of the core is adjusted to adjust the size of the lithium ion battery.

[0024]The following is a detailed description of the designed new core winding and stacking form:

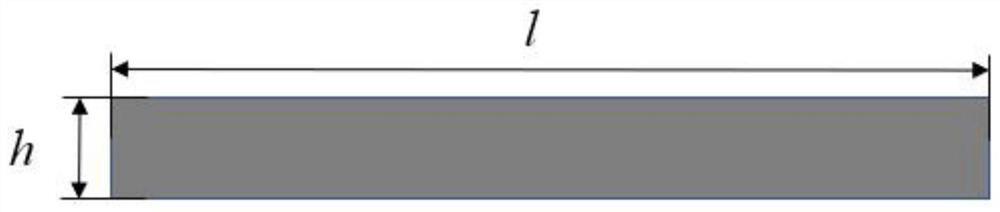

[0025]Such asfigure 1 As shown, the core before winding is a long strip with a length ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com