Novel assembled stator

A stator, a new type of technology, applied in the direction of electromechanical devices, electric components, magnetic circuit shape/style/structure, etc., can solve the problems of difficult to control concentricity, low assembly efficiency, and high assembly cost, to improve the slot area utilization rate, increase Service life, the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

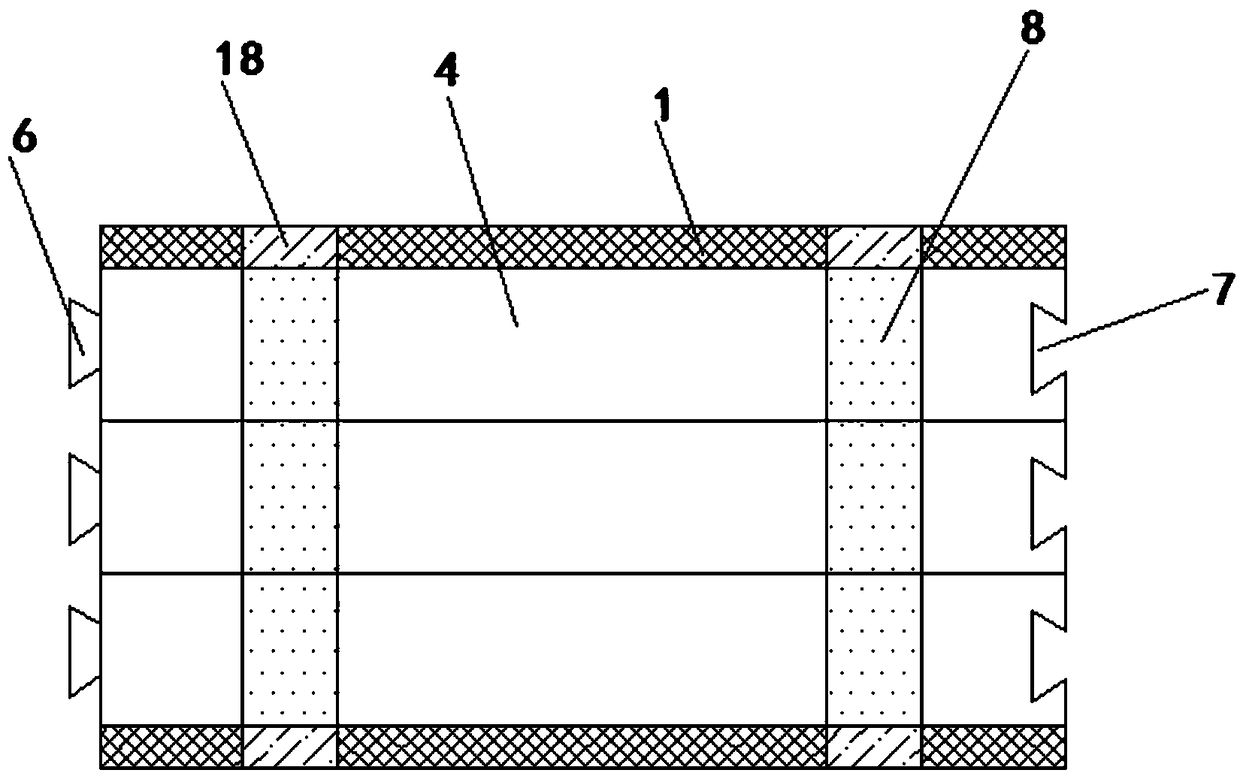

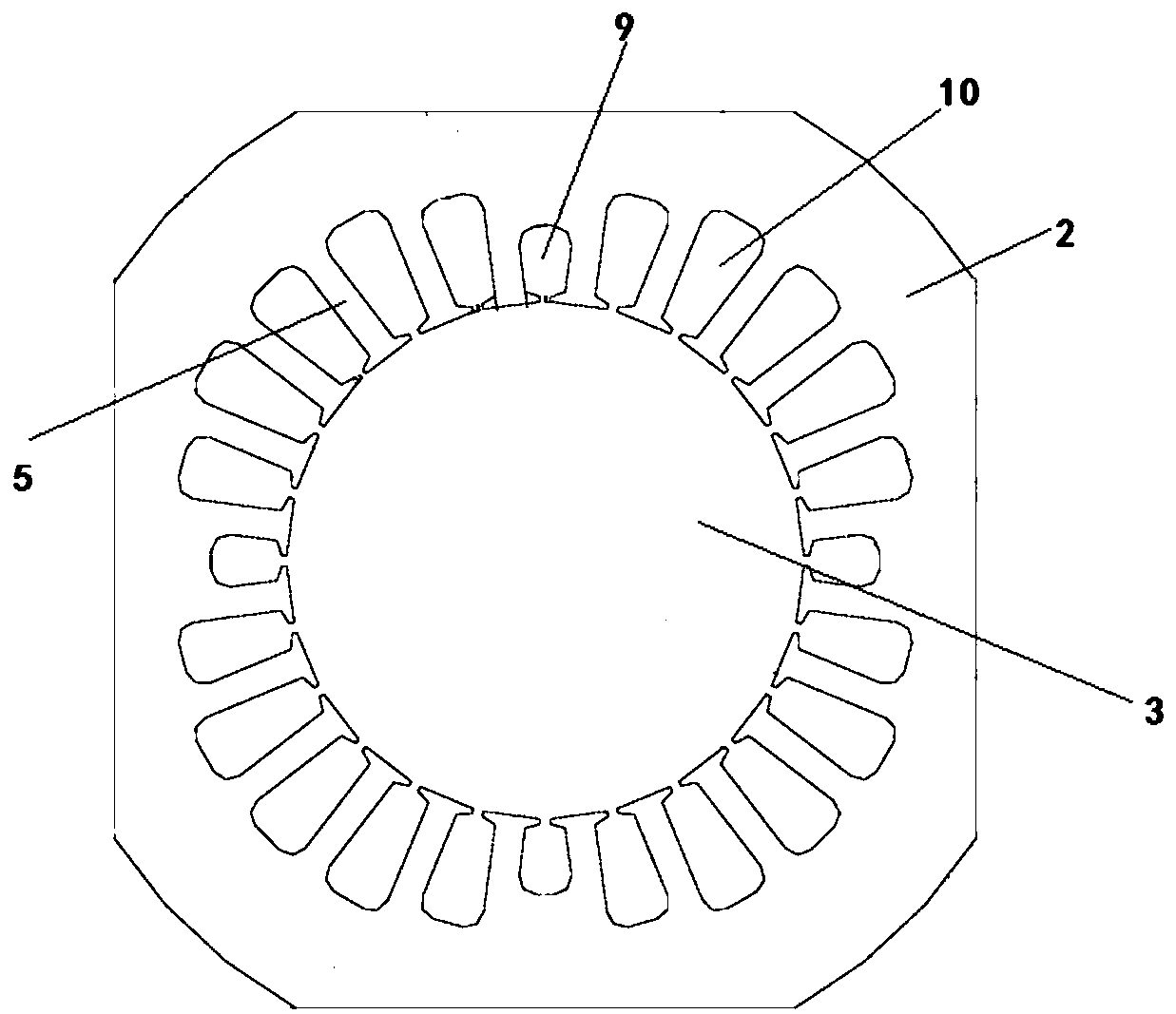

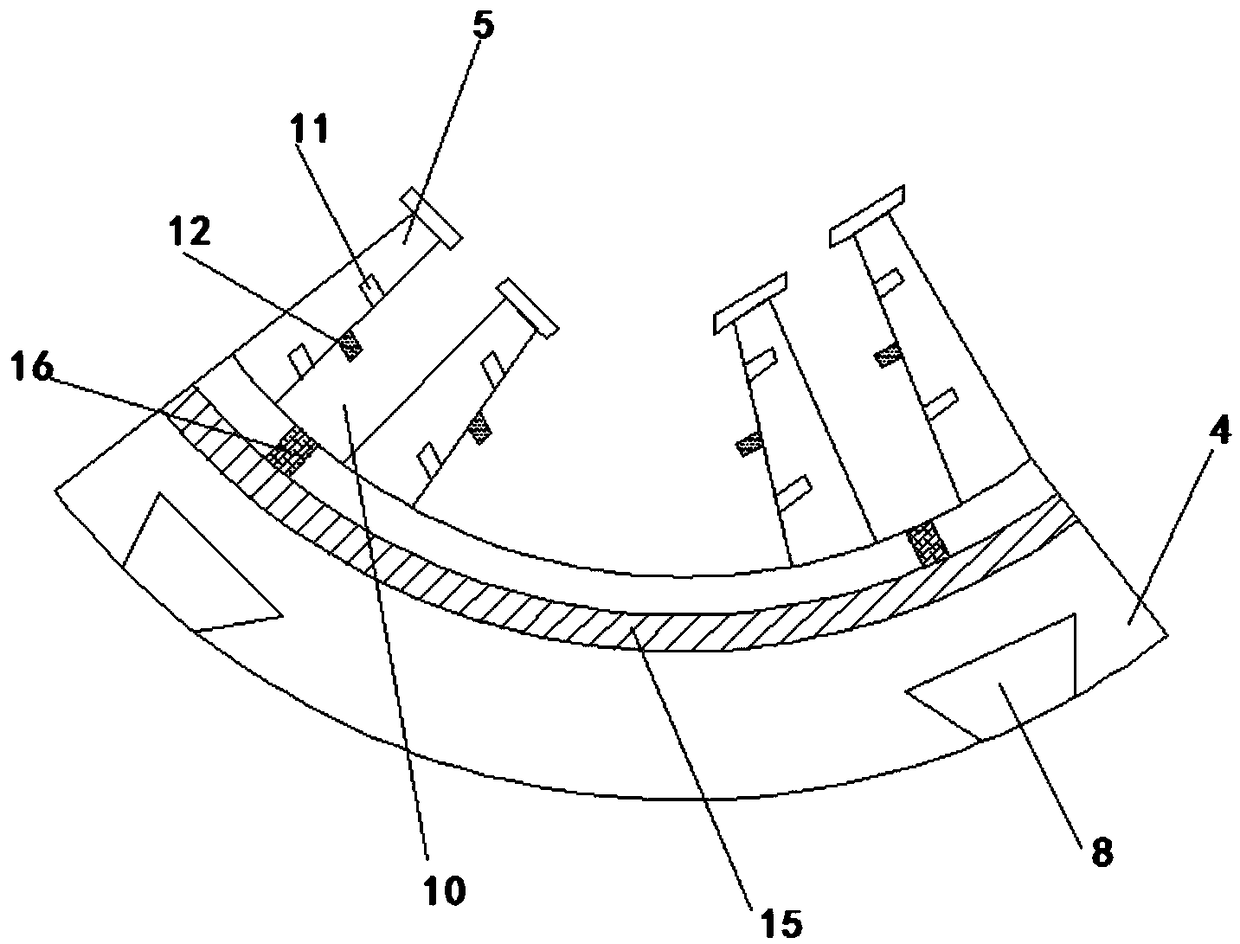

[0025] Embodiment 1: as Figure 1 to Figure 5 As shown, a new assembled stator includes a flange 1 and a stator body. The flange 1 and the stator body are detachably connected together. The stator body is detachably assembled by a plurality of iron cores 2. On the stator body A central hole 3 is provided, and a plurality of iron cores 2 are respectively detachably connected together around the central hole 3. The iron core includes a core body 4 and stator teeth 5, and a plurality of stator teeth 5 are provided and fixedly connected to the core body 4 respectively. One end of the core body 4 is provided with a horizontal fixing block 6, and the other end is provided with a horizontal positioning groove 7 corresponding to the horizontal fixing block 6, and the surface of the outer wall of the core body 4 is provided with an inwardly recessed longitudinal positioning groove 8, two When the iron core 2 is connected up and down, the two iron cores 2 are connected together through ...

Embodiment 2

[0035] Embodiment 2: as figure 1 with 5 As mentioned above, when assembling, the left and right adjacent iron cores 2 are connected together through the cooperation of the lateral positioning groove 7 and the lateral fixing block 6, and then the upper and lower adjacent iron cores 2 are assembled together through the positioning pins, and then passed The flange 1 is plugged together with the positioning pin through the fastening hole 18, and then the coil is wound on the stator tooth 5, and the coil can be well blocked by the limiting groove 11 and the limiting protrusion 12, improving the In addition, the V-shaped hook 17 can well block the coil and further improve its stability. The heat generated by the stator body during operation is dissipated through the heat dissipation through hole 16 and the heat dissipation scale 13. In addition, The heat dissipation through hole 16 is arranged in a trapezoidal shape. In the present invention, one end with a larger opening area face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com