Steaming and baking all-in-one machine

An all-in-one, steaming and roasting technology, which is applied in the field of steaming and roasting all-in-one machines, can solve problems such as internal consumption of heat energy, and achieve the effects of saving the cost of the whole machine, simple structure and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

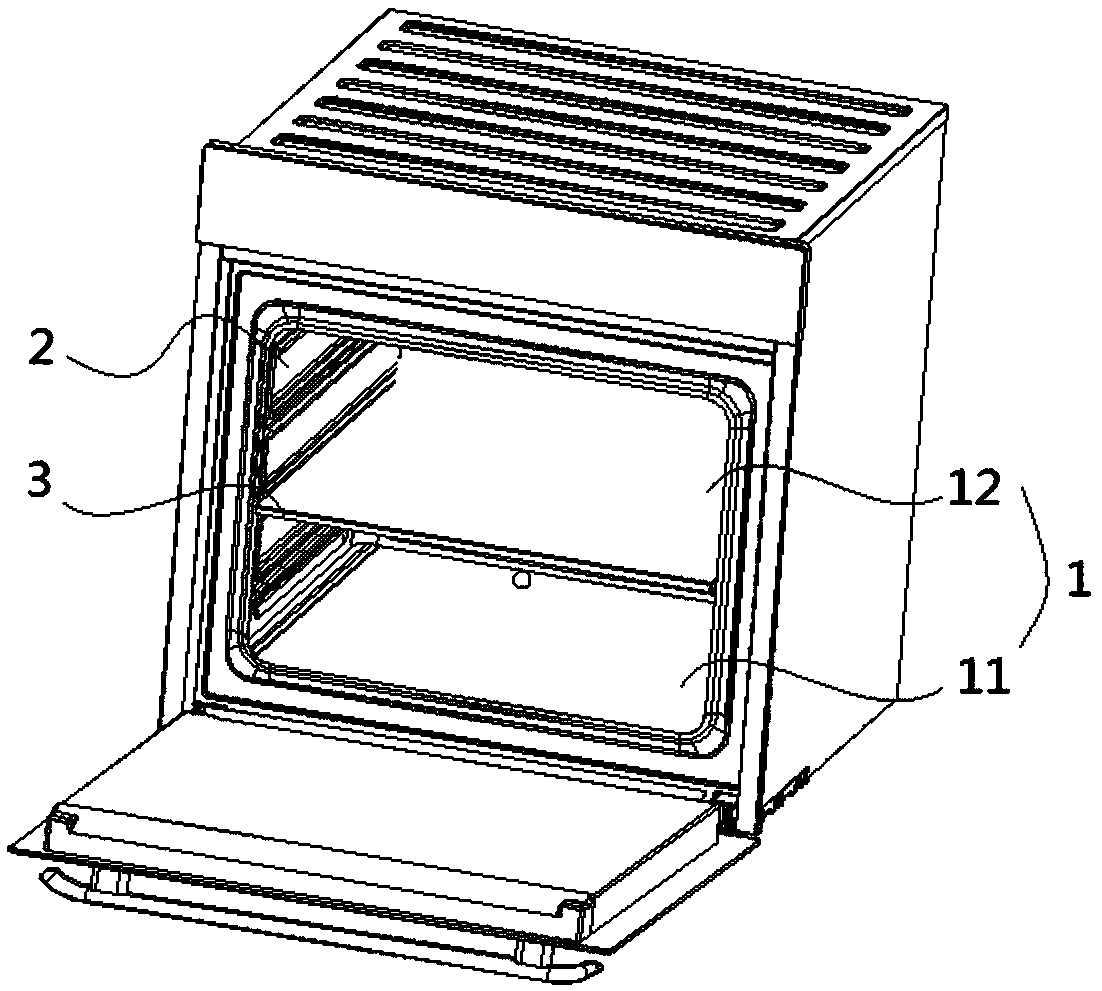

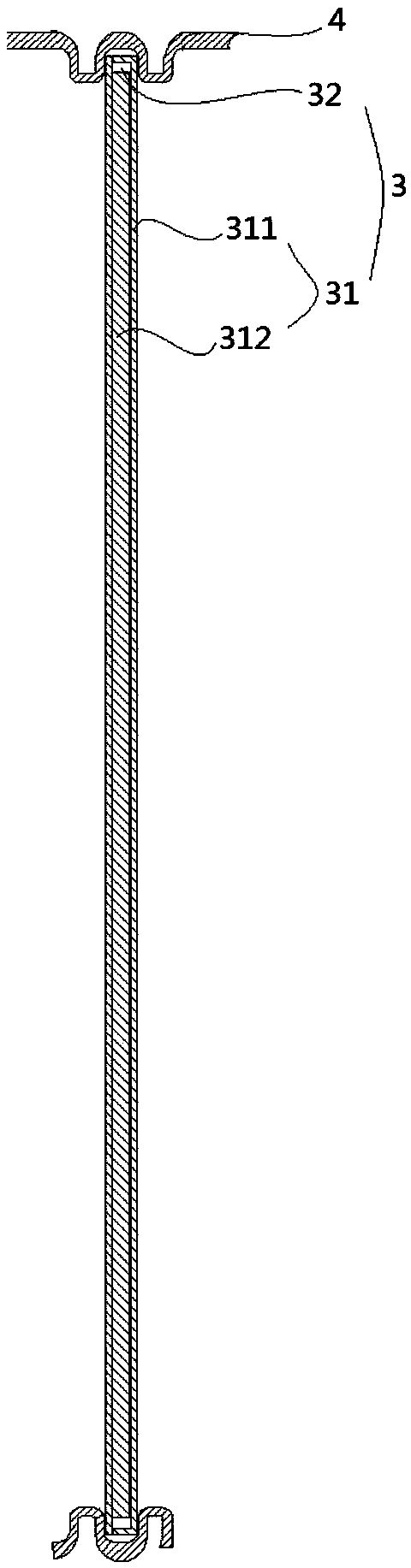

[0035] figure 1 and figure 2 Shown is an integrated steaming and roasting machine provided in this embodiment, including a cooking cavity 1. The cooking cavity 1 in this embodiment is formed by five inner walls 2 of the cavity and the door body of the integrated steaming and roasting machine. Square space; the heat insulation device 3 is connected on the inner wall 2 of the chamber opposite to the left and right; as figure 1 As shown, the cooking cavity 1 is divided into a steamer cavity 11 below the integrated steam-oven machine and an oven cavity 12 above the integrated steam-oven machine under the action of the heat insulating device 3 .

[0036] Share the same cooking space with the steaming and roasting function in the existing integrated steaming and roasting machine, the integrated steaming and roasting machine provided in this embodiment uses the heat insulation device 3 to divide the above-mentioned cooking cavity 1 into a steam box cavity 11 and an oven cavity 12 ...

Embodiment 2

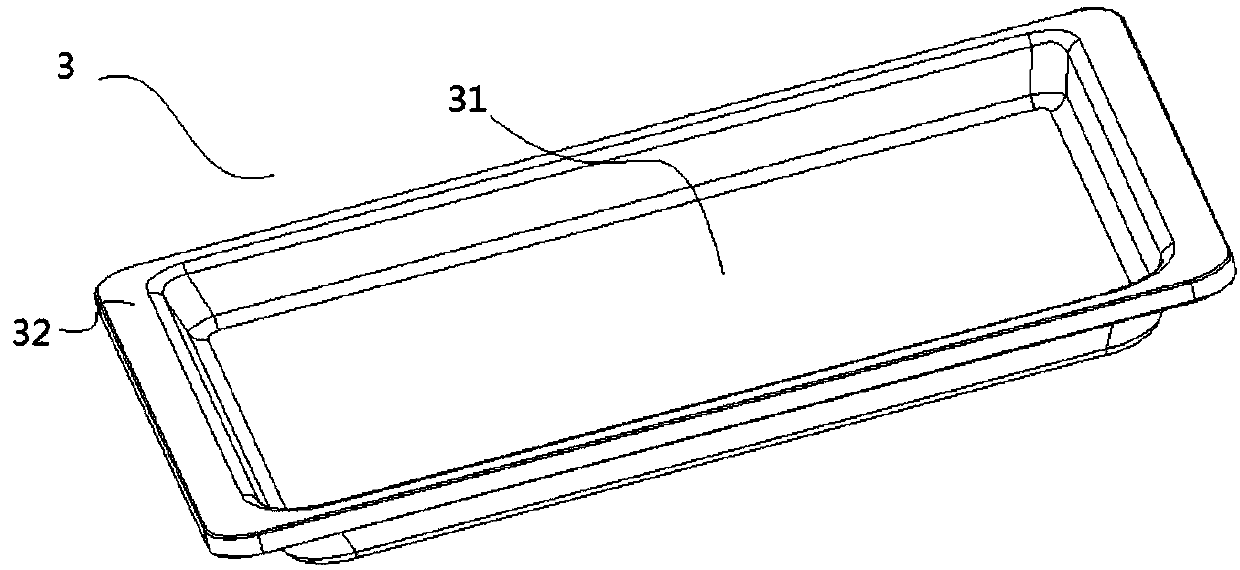

[0045] Figure 3 to Figure 5 As shown, it is an integrated steaming and roasting machine provided in this embodiment. Compared with Embodiment 1, the difference of this embodiment is that the shape of the above-mentioned support cover 311 is designed in the shape of a baking tray, such as image 3 As shown, the material of the support cover 311 is corrosion-resistant stainless steel SUS304, and the welding seam of the support cover 311 is smooth and polished to ensure the quality of the appearance.

[0046] In this embodiment, the heat insulation device 3 can be directly used as a baking pan in the integrated steaming and roasting machine without adding additional baking pan components, which saves the cost of the whole machine and is also convenient for users to use. However, when the thermal insulation device 3 is used in combination with the baking pan, the moisture condensed in the baking pan easily penetrates into the support cover 311 due to the problem of the welding se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com