Vertical lifting feeding system of automatic packaging machine for beef jerky

An automatic packaging machine, vertical lifting technology, applied in packaging and other directions, can solve the problems that the conveyor belt is not easy to achieve rapid and intermittent supply, reduce the working efficiency of the automatic packaging machine, and the conveyor belt is prone to accumulation, etc., to improve sliding stability and prevent insufficient material supply. , to avoid the effect of mechanical collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

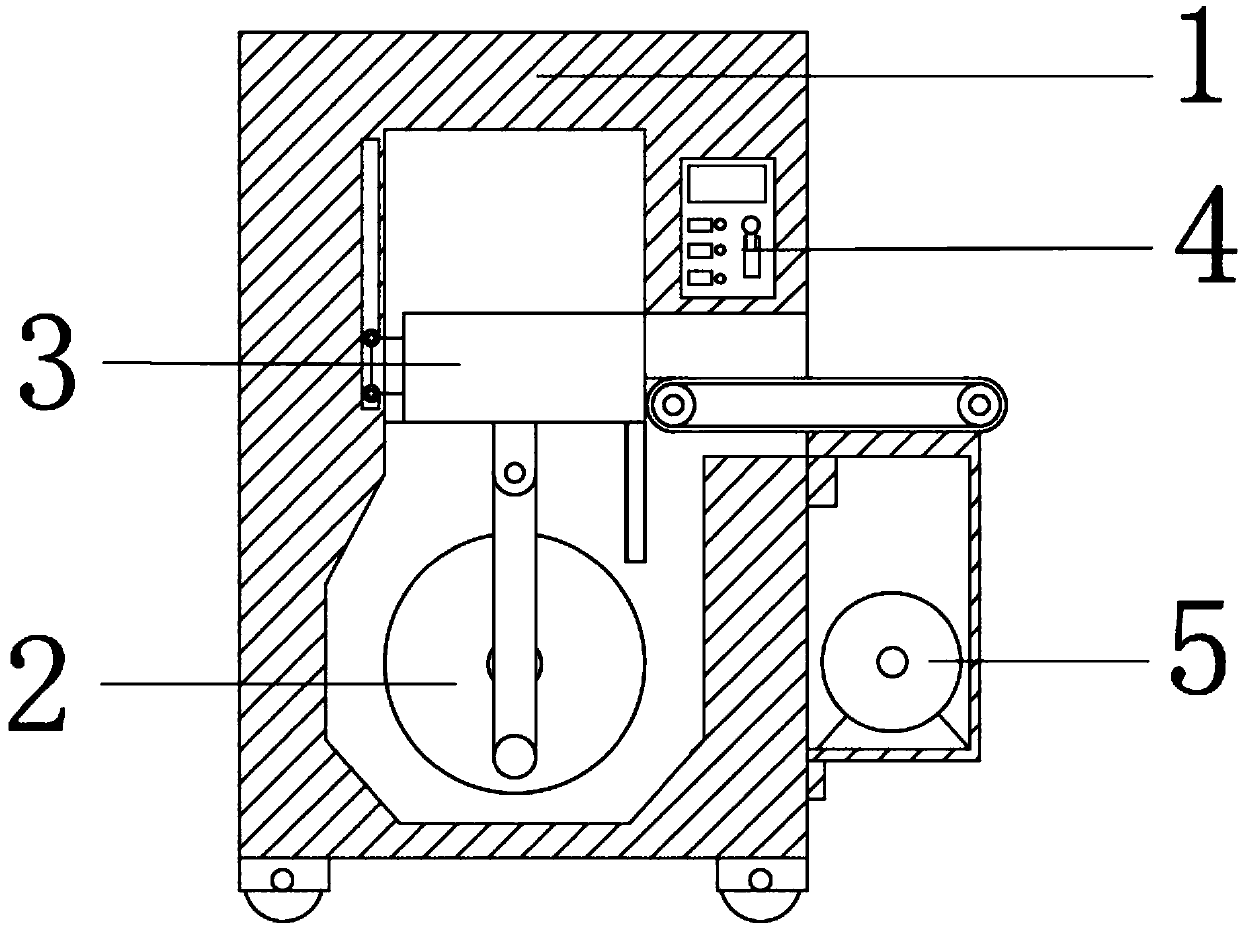

[0030] like Figure 1-6 As shown, the embodiment of the present invention provides a vertical lifting feeding system of an automatic beef jerky packaging machine. The inner cavity of the main equipment 1 of the feeding system is provided with a vertical lifting device 2, and the inner cavity of the main equipment 1 of the system corresponds to the vertical lifting device 2 The top of the tank is provided with a receiving box device 3, one side of the system main equipment 1 is provided with a feeding device 4, and the bottom of the feeding device 4 is provided with a power motor device 5, and during the feeding process, the feeding device 4 feeds the dried beef Transported to the receiving box device 3, the power motor device 5 inputs the power to the vertical lifting device 2, and the vertical lifting device 2 makes the receiving box device 3 rise vertically to realize the vertical feeding of the beef jerky automatic packaging machine, and the driven connection The rod 307 is...

Embodiment 2

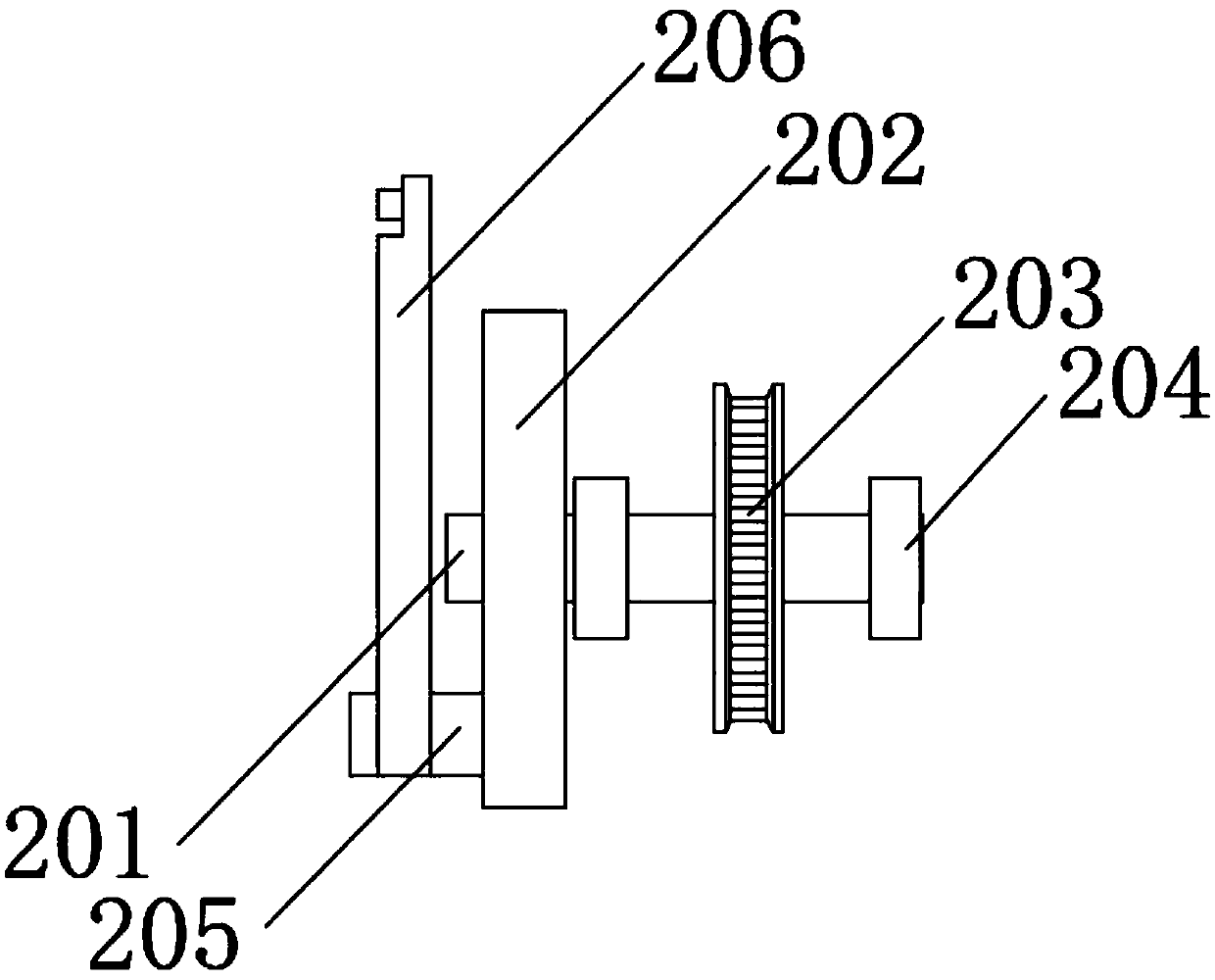

[0032] like figure 1 , 3 As shown, the embodiment of the present invention provides a vertical lifting feeding system of an automatic beef jerky packaging machine. The vertical lifting device 2 includes a power shaft 201, and an eccentric wheel 202 is connected in series with the axial surface of the power shaft 201. One of the eccentric wheels 202 The side away from the center of the wheel is fixedly connected with a fixed shaft 205, and the axial surface of the fixed shaft 205 is movably sleeved with an active connecting rod 206. A fixed bearing 204 is connected, and the axial surface of the power shaft 201 corresponds to the inner side of the fixed bearing 204. The driven pulley 203 is movably sleeved. The fixed bearing 204 can fix the position of the power shaft 201 to ensure that the power shaft 201 can rotate stably. The driven pulley 203 can input power to the power rotating shaft 201, and the power rotating shaft 201 drives the eccentric wheel 202 to rotate. When the ...

Embodiment 3

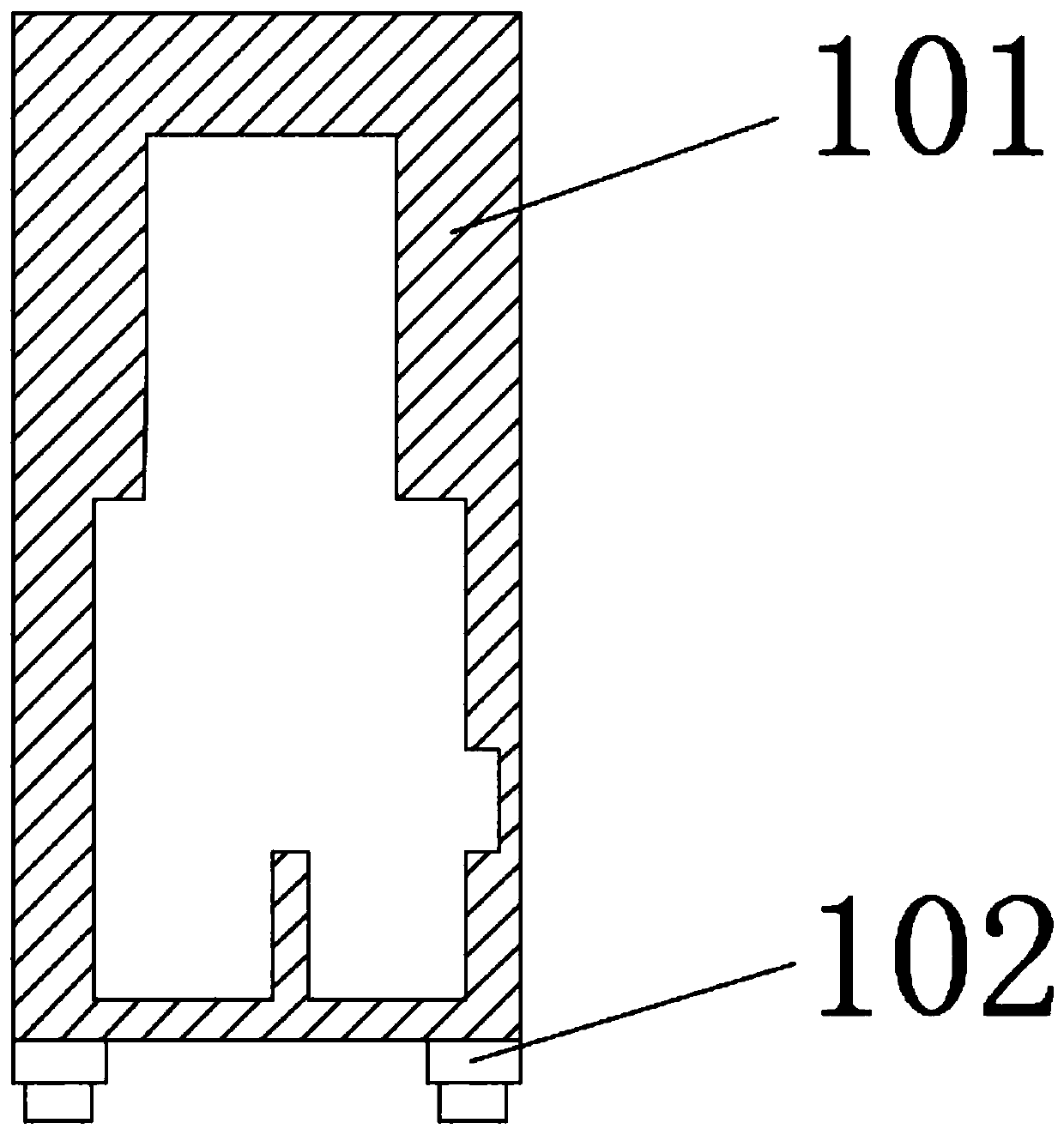

[0034] like figure 1 , 3 , 4, the embodiment of the present invention provides a vertical lifting feeding system of a beef jerky automatic packaging machine, the receiving box device 3 includes an adjustable receiving box 301, and the inner cavity of the adjustable receiving box 301 is embedded with a mobile The backboard 302, the inside of the adjustable material receiving box 301 corresponds to the bottom of the movable backboard 302, and a transmission screw 303 is provided, and the transmission screw 303 is engaged with the bottom surface of the mobile backboard 302, and the inside of the adjustable material receiving box 301 corresponds to the transmission screw 303 There is an adjustment gear 304 on the top of the top, and the adjustment gear 304 meshes with the transmission screw 303. The back of the adjustable receiving box 301 is fixedly connected with a fixed card 305, and the side of the fixed card 305 away from the adjustable receiving box 301 is movably connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com