Garbage can capable of realizing in-can air sterilization and automatic bag-sleeving

A trash can and inner air technology, applied in the field of trash cans, can solve the problems that the trash can cannot be automatically bagged, breeds bacteria, emits peculiar smell, etc., and achieves the effect of preventing ultraviolet leakage, reducing peculiar smell and preventing the spread of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

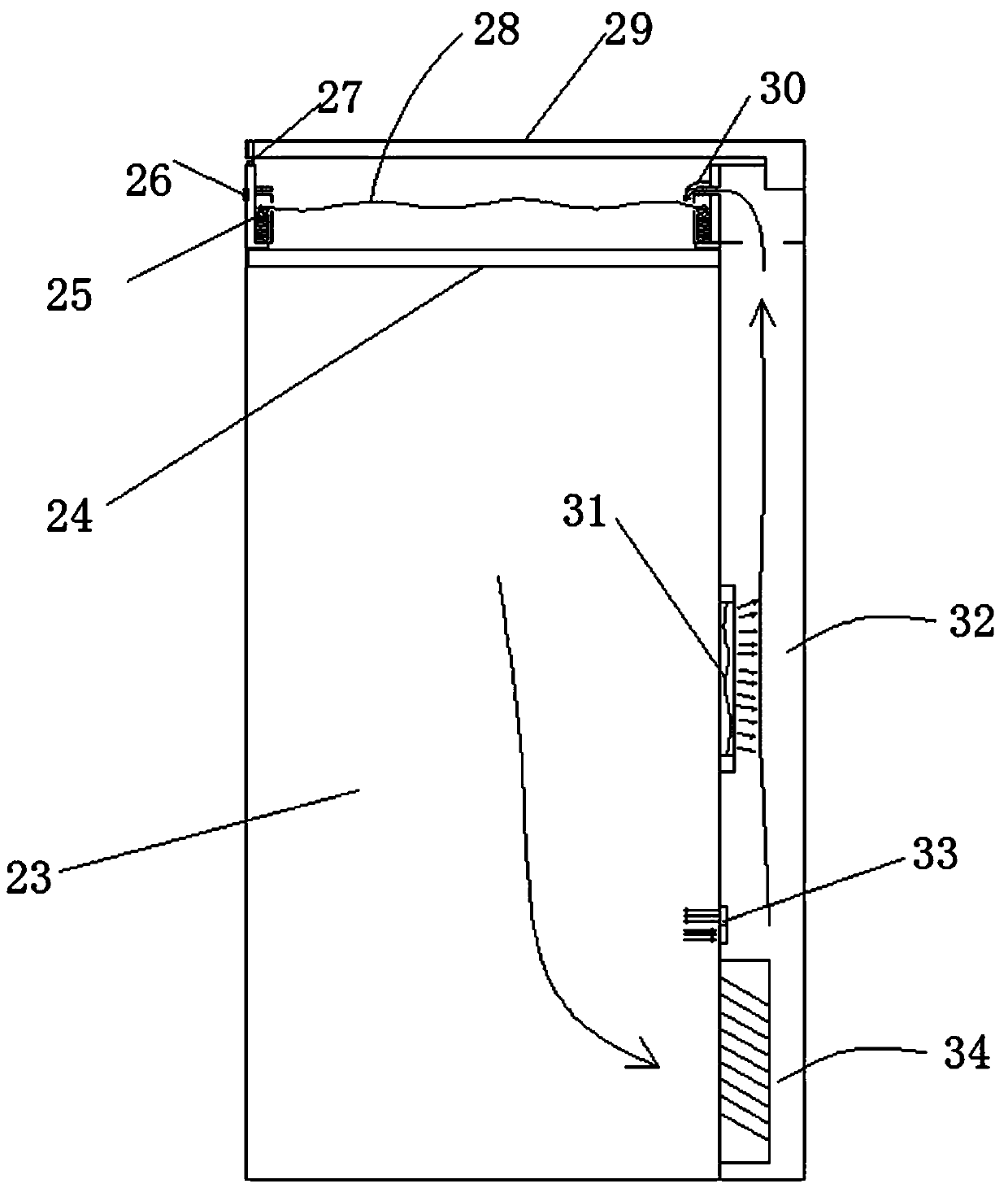

[0038]The present invention proposes a garbage bin with air sterilization in the bucket and automatic bagging, which can automatically carry out the operation of opening the lid and bagging, and combined with the air duct structure of upper positive pressure and lower negative pressure, bagging is easier and will not occur. After bagging, there are air bubbles between the garbage bag and the barrel wall, which makes the bagging more perfect, such as Figure 1-Figure 5 As shown, the following setting method is adopted in particular: a mechanical structure and a circuit mechanism for controlling the mechanical structure are provided, the mechanical structure includes a barrel body 23 and an automatic cover bagging structure matched with the barrel body 23, and the automatic cover opening The bagging structure is hinged on the barrel body 23; the side wall of the barrel body 23 is provided with an air duct 32 capable of forming positive pressure and negative pressure on the trash ...

Embodiment 2

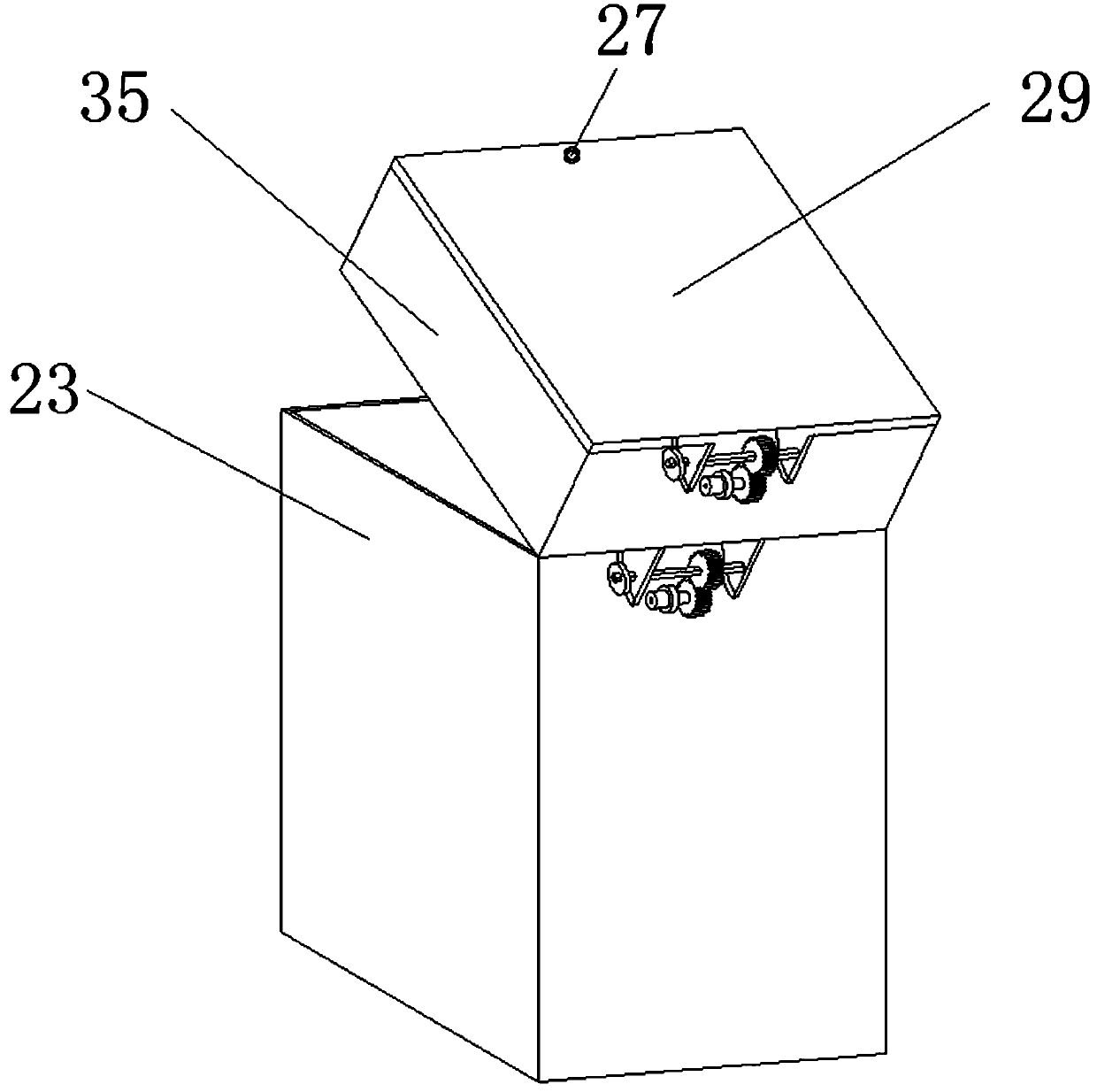

[0041] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, such as Figure 1~5 As shown, the following arrangement structure is adopted in particular: the automatic cover bagging structure includes a garbage can cover 35, and a garbage bag storage cavity 25 and a fuse sealing device 24 are arranged in the garbage can cover 35, and the garbage can cover 35 passes through A cover opening system is hinged on the barrel body 23, the fuse sealing device 24 is arranged near the barrel body 23, the garbage bag storage cavity 25 is arranged above the fuse seal device 24, and a baffle plate 30 is arranged above the garbage bag storage cavity 25; The mechanism is electrically connected with the cap opening system at the hinged joint of the fusing sealing device 24 and the barrel body 23 .

[0042] As a preferred setting scheme, the automatic lid opening and bagging structure is provided with a trash can l...

Embodiment 3

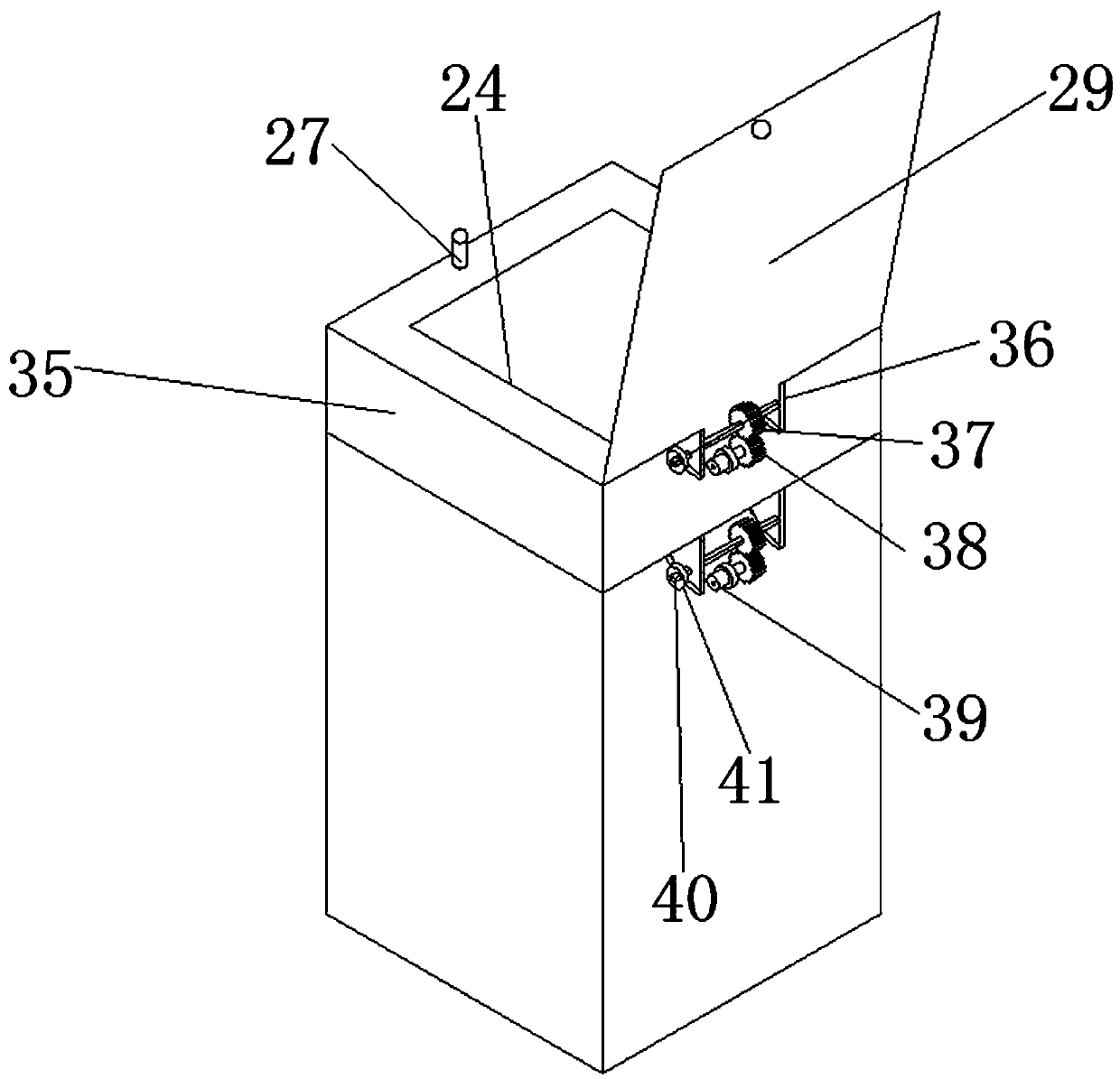

[0052] This embodiment is further optimized on the basis of any of the above embodiments, further to better realize the present invention, such as Figure 1~5 As shown, the following arrangement structure is adopted in particular: the cover opening system includes a rotating shaft fixing plate 36, a second gear 37, a first gear 38, a drive motor 39, a rotating shaft 40 and a bearing 41, and the rotating shaft fixing plate 36 hinges the garbage The bucket cover 35 and the bucket body 23, the rotating shaft 40 runs through the second gear 37 and is arranged on the rotating shaft fixed plate 36, the driving motor 39 is connected with the first gear 38, the first gear 38 is meshed with the second gear 37, and the bearing 41 is arranged on the at both ends of the axis of rotation 40 .

[0053] As a preferred arrangement, two rotating shaft fixing plates 36 are provided, a rotating shaft 40 is arranged between the two rotating shaft fixing plates 36, a bearing 41 is respectively arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com