Method for eliminating annealing white spot on edge of cold-rolled aluminum coil

An annealing and aluminum coil technology, applied in the field of aluminum alloy heat treatment, can solve problems such as white spot defects in aluminum coils, and achieve the effect of reducing the air entering the gap between layers, reducing the reaction between aluminum and oxygen, and reducing the gap between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

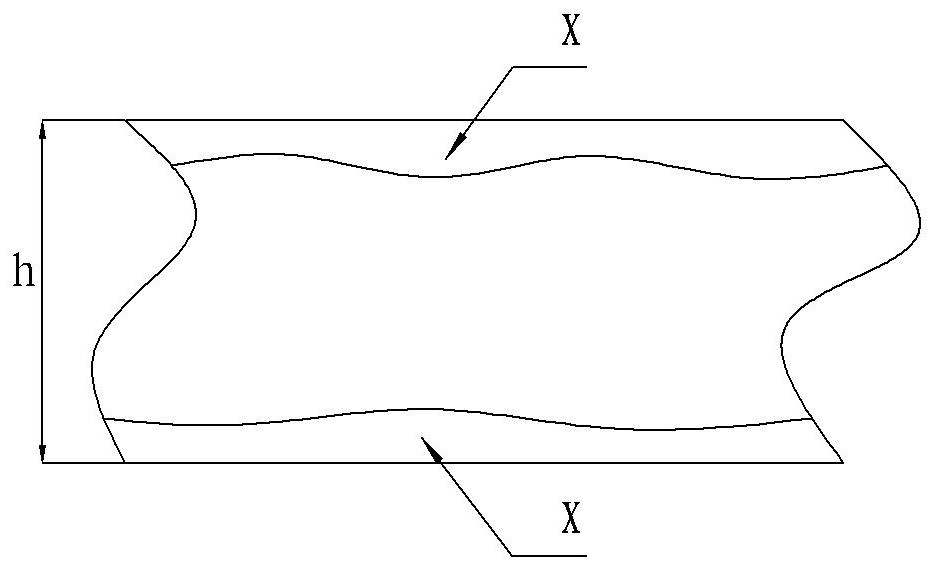

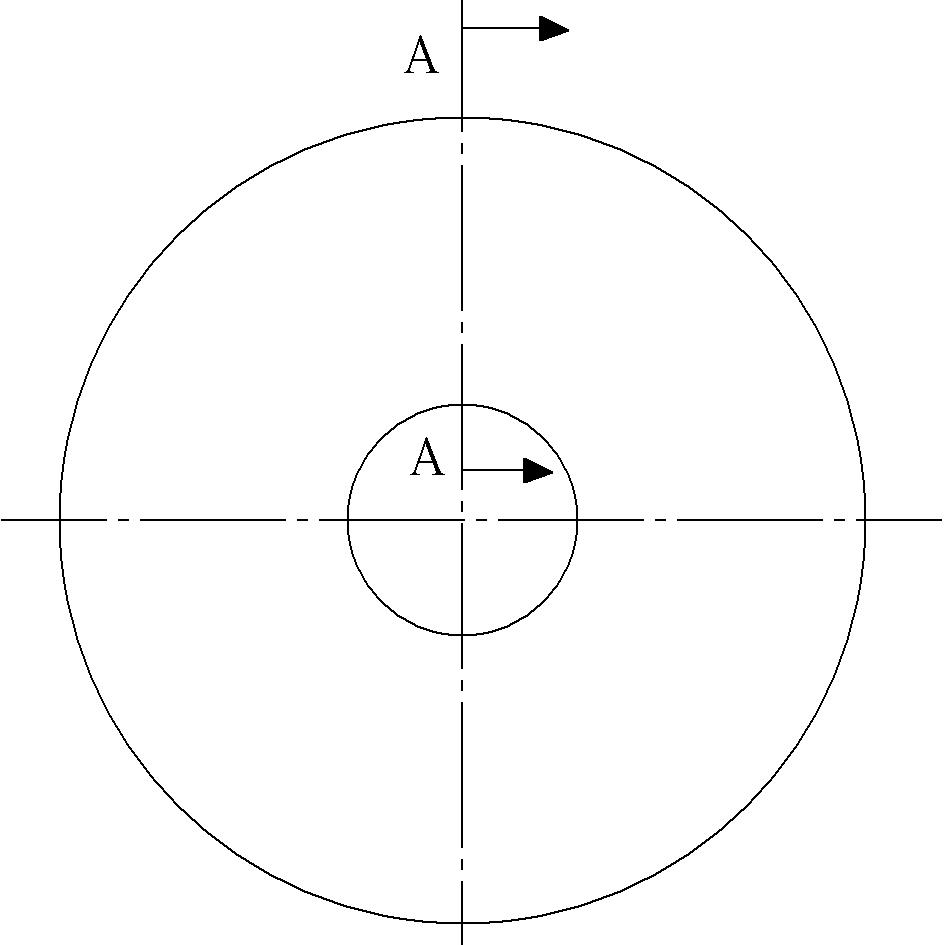

[0023] The method for eliminating the annealing white spots at the edge of cold-rolled aluminum coils is to process aluminum coil 1, alloy 1235, thickness 4.0mm, and width 1350mm, including the following steps:

[0024] A. Before complete annealing, the aluminum coil rolling pass; the actual convexity is controlled at 0;

[0025] B. Control the coiling tensile stress before annealing at 25MPa;

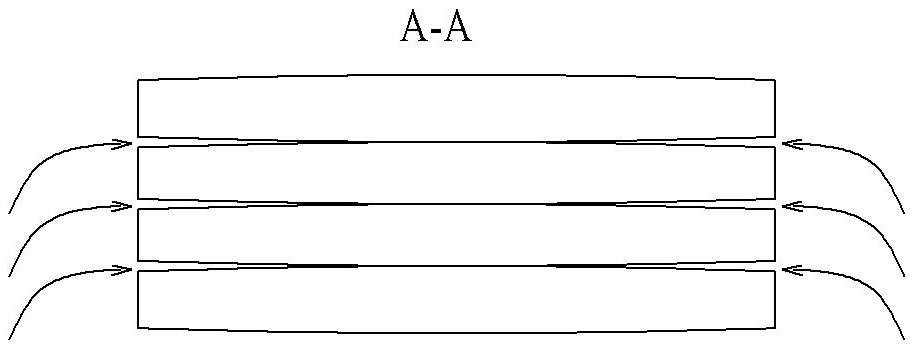

[0026] C. Make a steel strip at 40mm on both sides of the aluminum coil;

[0027] D. Then perform annealing. The annealing furnace gas temperature is 550°C and the material temperature is 500°C. After 5 hours of heat preservation, the program stops and cools with the furnace. Turn off the blowing and washing fans and negative pressure fans, and open the side cooling system. When the material temperature drops below 150°C Time to release. After cooling to room temperature, the book was opened for inspection, and no annealed white spots were found.

Embodiment 2

[0029] The method for eliminating the annealing white spots at the edge of cold-rolled aluminum coils is to process aluminum coil 2, alloy 5052, with a thickness of 1.17 mm and a width of 1350 mm, including the following steps:

[0030] A. Before complete annealing, the rolling pass of aluminum coil; the actual convexity is controlled at 0.2%;

[0031] B. Control the coiling tensile stress before annealing at 50MPa;

[0032] C. Make a steel strip at 120mm on both sides of the aluminum coil;

[0033] D. Then carry out annealing. The gas temperature of the annealing furnace is 380°C, and the material temperature is 320°C. After 3 hours of heat preservation, the program stops, the blowing and washing fans and negative pressure fans are turned off, and the side cooling system is turned on. The material temperature drops to 200°C before being released from the furnace. After cooling to room temperature, the book was opened for inspection, and no annealed white spots were found.

Embodiment 3

[0035] The method for eliminating the annealing white spots at the edge of cold-rolled aluminum coils is to process aluminum coil 2, alloy 5052, with a thickness of 1.17 mm and a width of 1350 mm, including the following steps:

[0036] A. Before complete annealing, the rolling pass of aluminum coil; the actual convexity is controlled at 0.1%;

[0037] B. Control the coiling tensile stress before annealing to be above 35MPa;

[0038] C. Make a steel strip at 80mm on both sides of the aluminum coil;

[0039] D. Then perform annealing. The temperature of the annealing furnace gas is 450°C, and the material temperature is 450°C. After 3 hours of heat preservation, the program stops, the blowing and washing fans and negative pressure fans are turned off, and the side cooling system is turned on. The temperature of the material drops to 175°C before being released from the furnace. After cooling to room temperature, the book was opened for inspection, and no annealed white spots w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com