Throttling stop valve and air conditioner with throttling stop valve

A throttling globe valve and throttling valve technology, applied in the direction of fluid circulation arrangement, mechanical equipment, refrigeration components, etc., can solve the problems of the globe valve not having throttling function, high space occupancy rate, low production efficiency, etc. The effect of compactness, low production and maintenance costs, improved production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

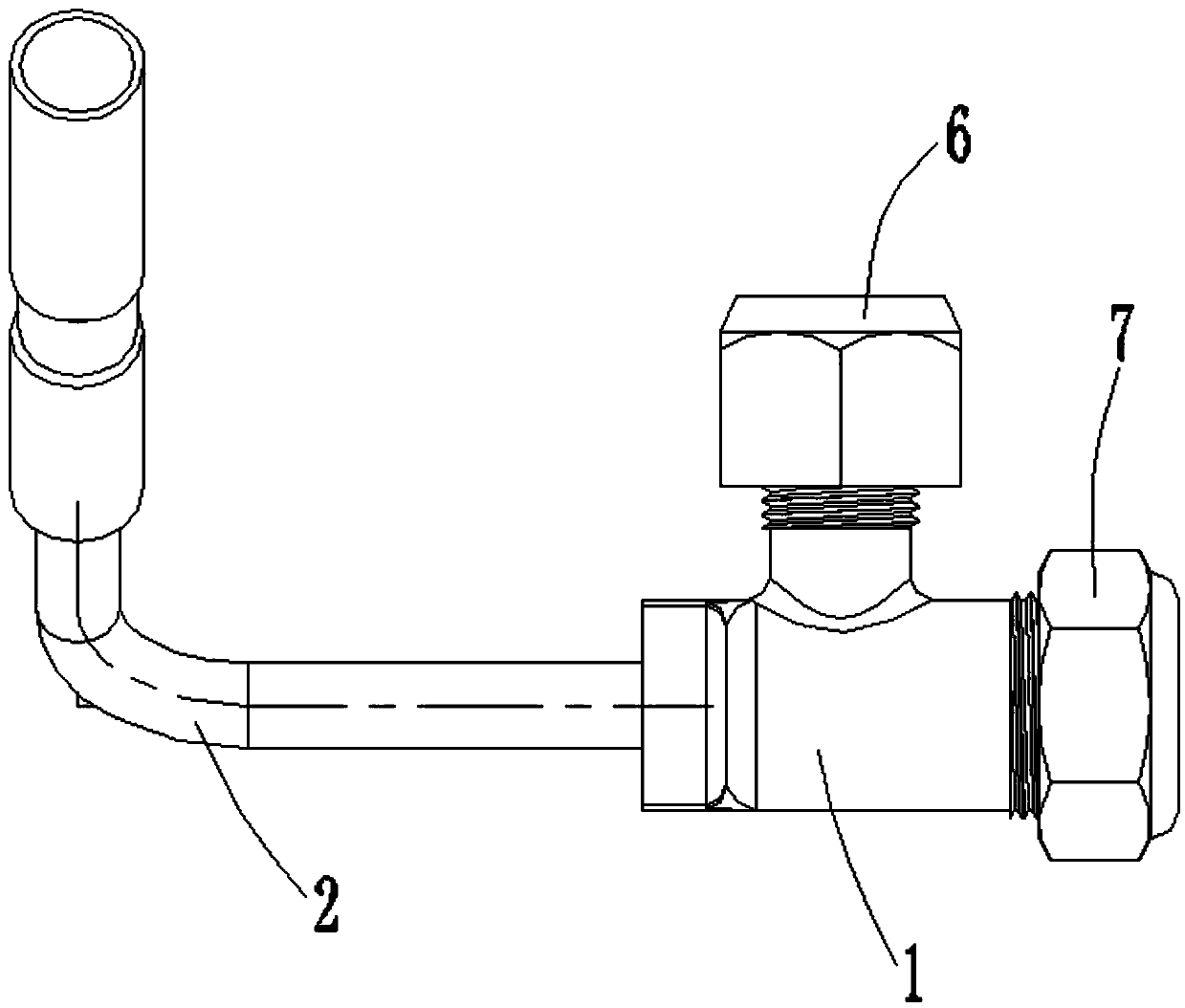

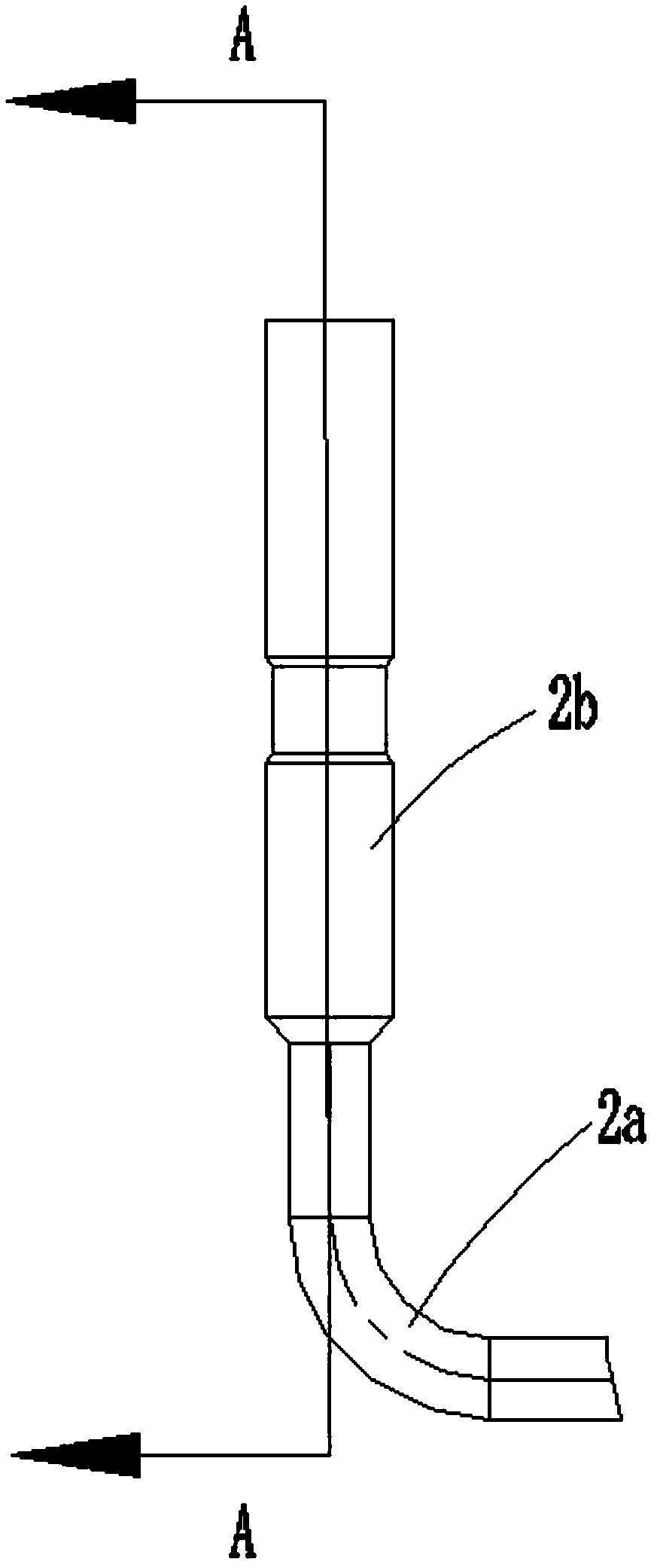

[0041] Throttle stop valve, with cut-off and throttling functions, can reduce production costs, increase production efficiency, and improve quality, such as figure 1 , figure 2 , image 3 As shown, specifically set to the following structure:

[0042] Including a commonly used stop valve, the stop valve includes a stop valve body 1, the stop valve body has three through holes communicating with each other, the three through holes have three ports, one port is used to connect with the connecting pipe 2, and one port Plastic screw 6 is worn when not in use, and a port is worn with copper nut 7 when not in use. There is a shut-off valve seat in the shut-off valve main body 1, and a shut-off valve spool is installed in the shut-off valve main body 1 and at the shut-off valve seat, and a connecting pipe 2 is threadedly connected to a port of the shut-off valve main body 1. 2 is L-shaped as a whole, and a throttling structure is installed in the connecting pipe 2, and the thrott...

Embodiment 2

[0047] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, especially adopt the following configuration structure:

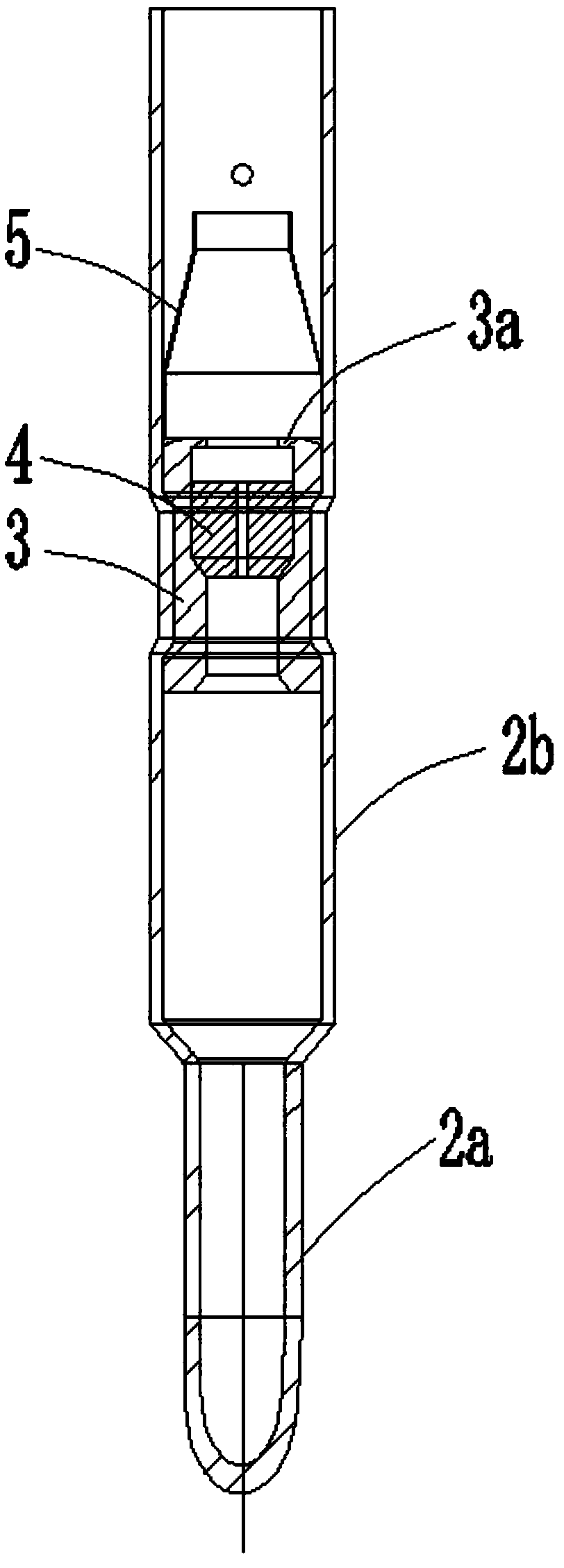

[0048] The throttling stop valve also includes a filter structure installed in the straight pipe 2b, and the filter structure is located upstream of the throttling structure, and the refrigerant first passes through the filter structure and then passes through the throttling structure. The filter structure is used to filter the impurities that exist or may exist in the refrigerant, purify the circulating refrigerant, and avoid the impact of impurities on the structural components of the circulation system.

[0049] Specifically, the filter structure is a filter screen 5 with a narrow top and a wide bottom. The beginning of the filter screen 5 is a filter surface, and the filter surface is surrounded by a conical surface. The end of the filter screen 5 is a cylindrical section. On ...

Embodiment 3

[0052] On the basis of the above embodiments, this embodiment also provides an air conditioner with a throttle cut-off valve, including the throttle cut-off valve in Embodiment 2. It plays the role of throttling and filtering, and the quite throttling and pressure-reducing filter device is integrated with the stop valve, which can cancel other throttling devices of the air conditioner, reduce costs and procedures, and improve quality. The connecting pipe of the throttle stop valve is installed on a refrigerant discharge port of the air conditioner. The air conditioner adopting the throttling stop valve is more convenient in installation, maintenance and replacement, has lower production and maintenance costs, and does not occupy too much installation space. It has the functions of cut-off and throttling, and can reduce the throttling valve set separately, which is convenient for production assembly and maintenance and replacement, reduces production cost, and improves producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com