Mounting structure of grid-method mixed sampling device for outlet flue gas of denitrification device

A technology of mixed sampling and installation structure, applied in the direction of sampling device, measuring device, sampling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

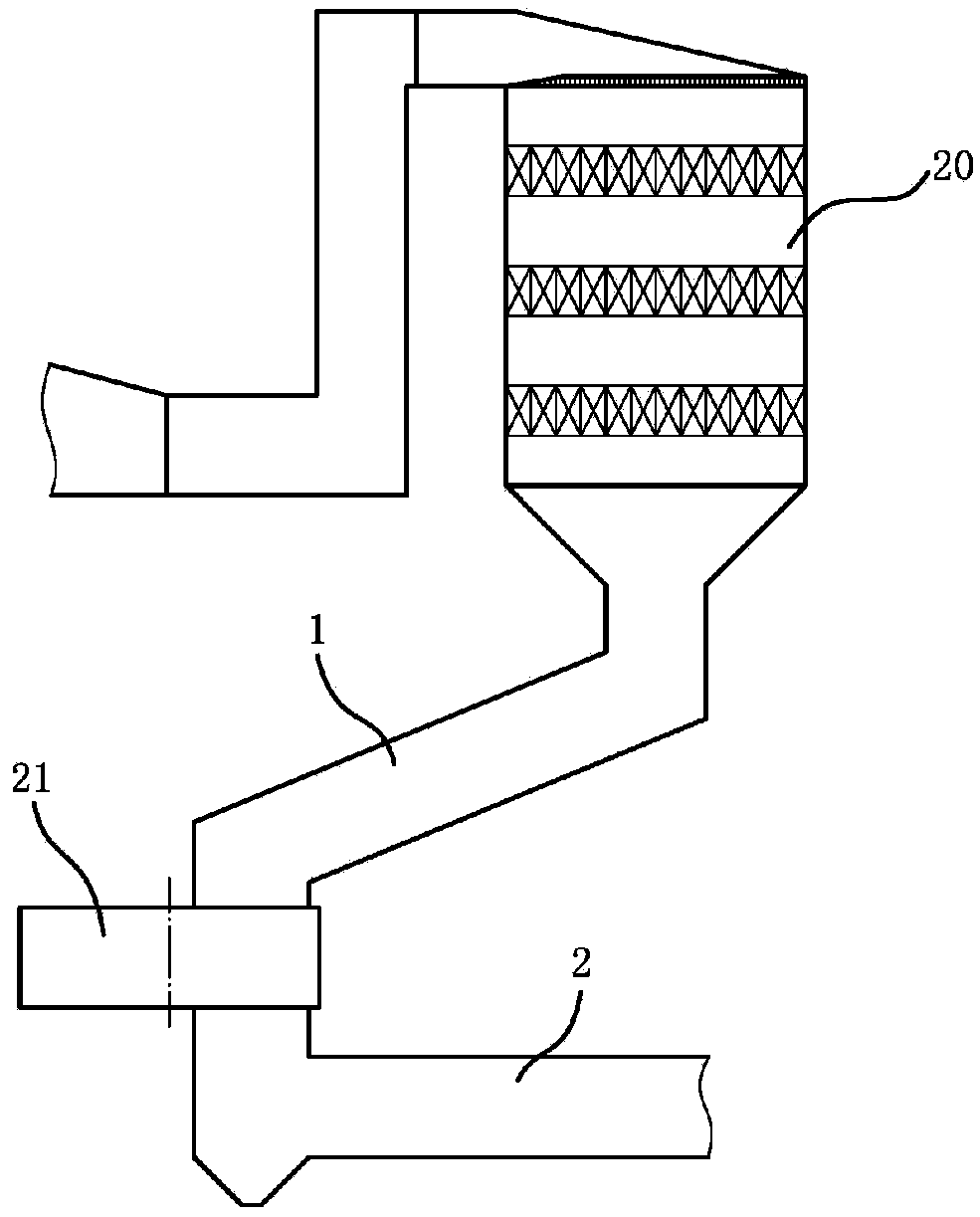

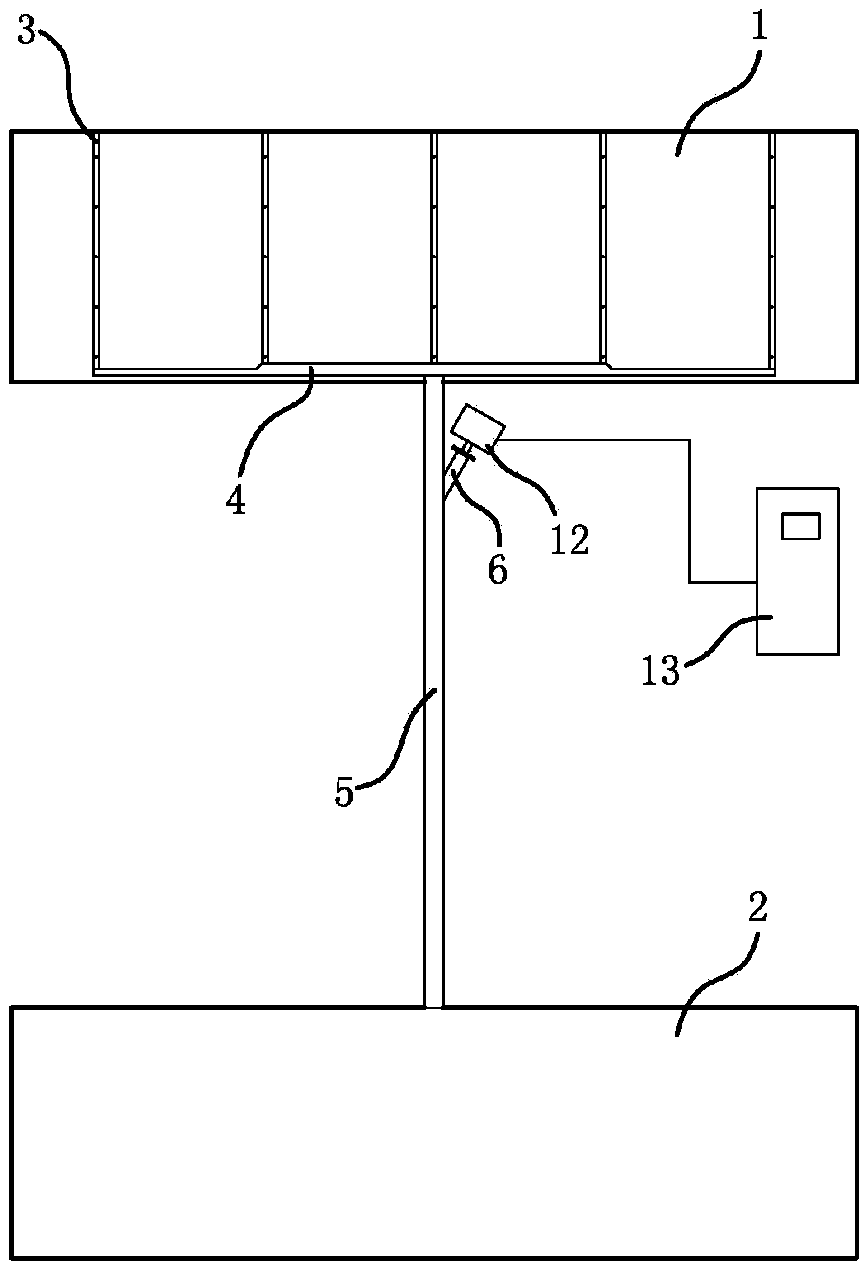

[0037] Such as figure 2 As shown, the installation structure of a flue gas grid method mixed sampling device at the outlet of a denitrification device includes the outlet flue of the denitrification device and the outlet flue of the air preheater, and also includes multi-point sampling pipes, variable cross-section confluence pipes, sampling master pipes and Sampling cavity of NOx measuring instrument; there are 5 multi-point sampling tubes, and they are vertically installed on the cross-section of the outlet flue of the denitrification device at equal intervals, and each multi-point sampling tube is equipped with 5 sampling holes; Two different cross-sectional sizes, the cross-sectional size gradually increases from both ends to the middle position, and the variable cross-section confluence pipe has a symmetrical structure at both ends; Both are connected with the variable cross-section confluence pipe; the sampling main pipe is arranged outside the outlet flue of the denitrif...

Embodiment 2

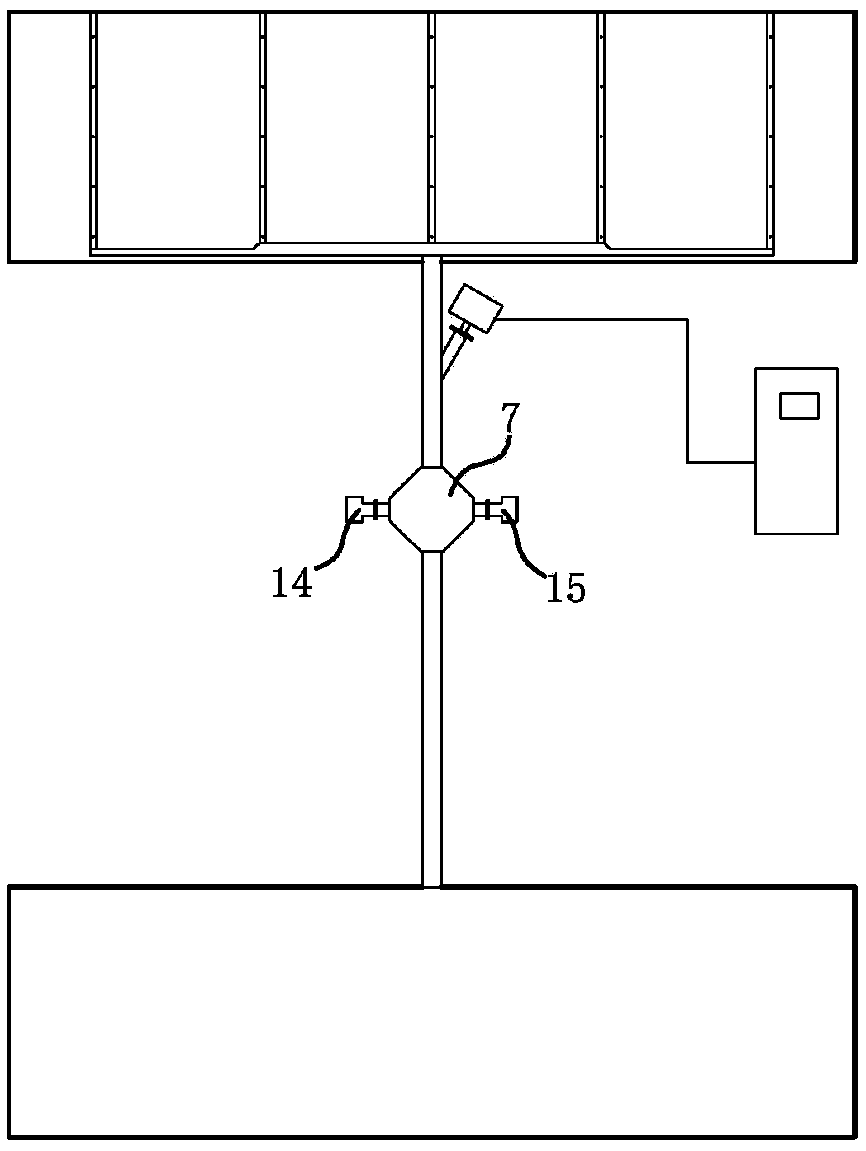

[0041] Such as image 3 As shown, it is basically the same as in Example 1, the difference is: the sampling main pipe is also provided with NH 3 Fugitive gauge sampling chamber, NH 3 The sampling cavity of the fugitive measuring instrument is located downstream of the sampling cavity of the NOx measuring instrument, NH 3 The sampling cavity of the escape measuring instrument is a quadrilateral structure, and the two opposite corners of the sampling cavity are connected in series on the sampling mother pipe, and the other two opposite corners are respectively equipped with the transmitting end and the receiving end of the laser probe.

Embodiment 3

[0043] Such as Figure 4 As shown, it is basically the same as Example 2, the difference is: in order to prevent the low differential pressure of the air preheater during the start and stop phase, the low temperature of the flue gas and the low flow rate of the flue gas in the sampling device lead to the occurrence of ash and condensate in the above sampling device ( condensate will further lead to vicious ash plugging), the sampling main pipe is also equipped with a restrictor, anti-blocking protection valve, differential pressure transmitter and temperature measuring point, wherein the restrictor is located upstream of the anti-blocking protection valve, all The measuring instrument is located upstream of the restrictor, and the positive pressure end of the differential pressure transmitter is connected upstream of the restrictor, NH 3 On the sampling main pipe downstream of the sampling cavity of the escape measuring instrument, the negative pressure end of the differential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com