G2 continuous Bezier cutter path smoothing algorithm based on tolerance zone

A smoothing algorithm and tool path technology, used in computer control, instruments, simulators, etc., can solve problems such as poor real-time and locality, and can not guarantee that the longest distance of the spline curve does not exceed the set value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be further described in detail below in conjunction with examples of implementation.

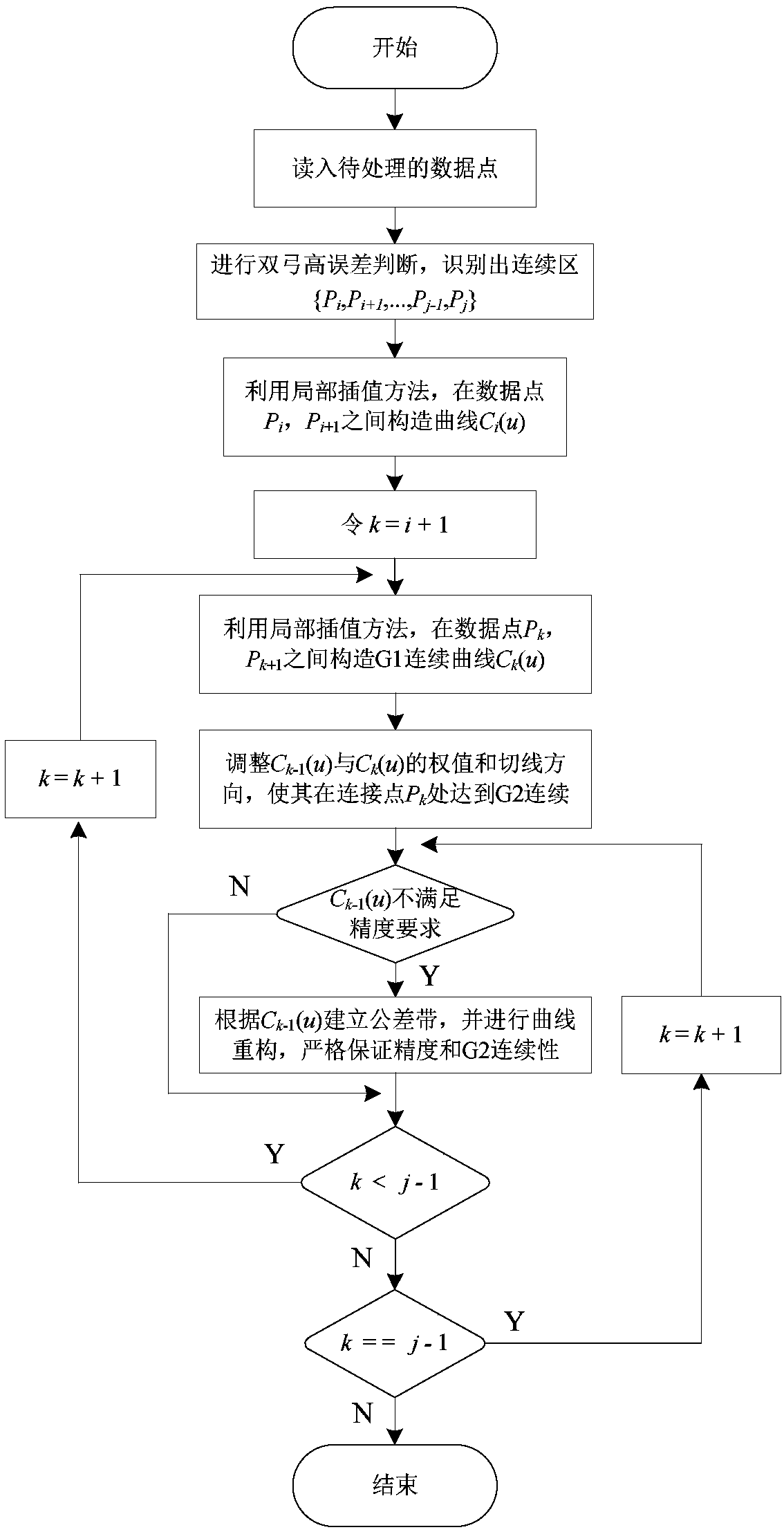

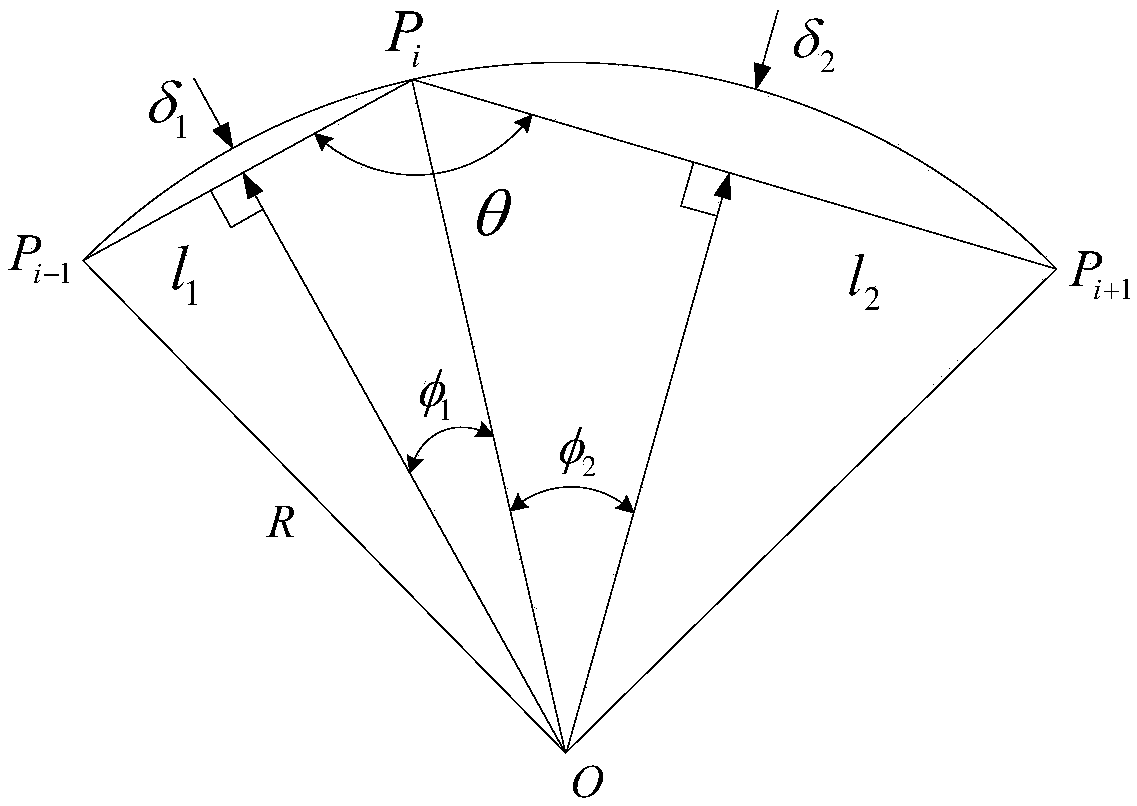

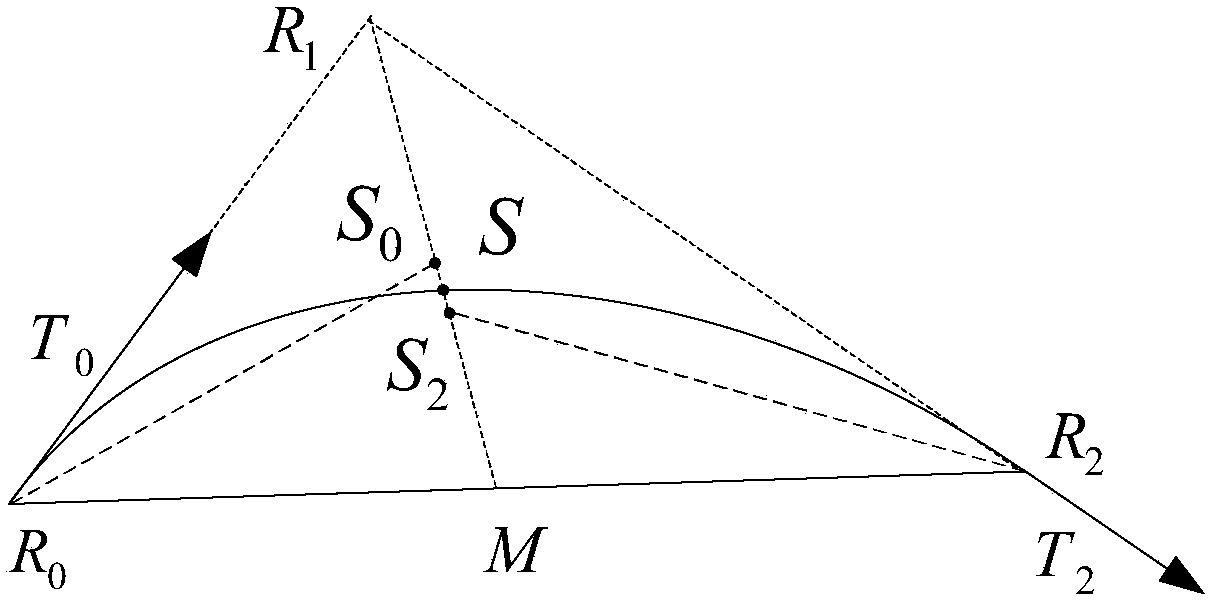

[0083] The invention is a G2 continuous Bézier tool trajectory smoothing algorithm based on tolerance zone, and according to the double-bow height error limit, the continuous tiny line segment processing area is identified from the processing path composed of discrete small line segments. For the continuous micro-segment processing area, firstly, local interpolation is performed on the discrete instruction points, and the broken-line processing path is converted into a G1 continuous quadratic rational Bézier curve; then, the weight and connection of two adjacent quadratic rational Bézier curves are adjusted The tangent direction at the point makes the machining path achieve G2 continuity; finally, by establishing a tolerance zone, the quadratic rational Bézier curve that does not meet the accuracy requirements is reconstructed.

[0084] The invention provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com