Tin-based binary eutectic alloy microstructure simulation and finite element solution analysis method

A binary eutectic, microstructure technology, applied in the direction of instrumentation, design optimization/simulation, calculation, etc., can solve problems such as inability to achieve solution analysis, achieve fast loading solution and analysis, improve modeling efficiency, programming and processing convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

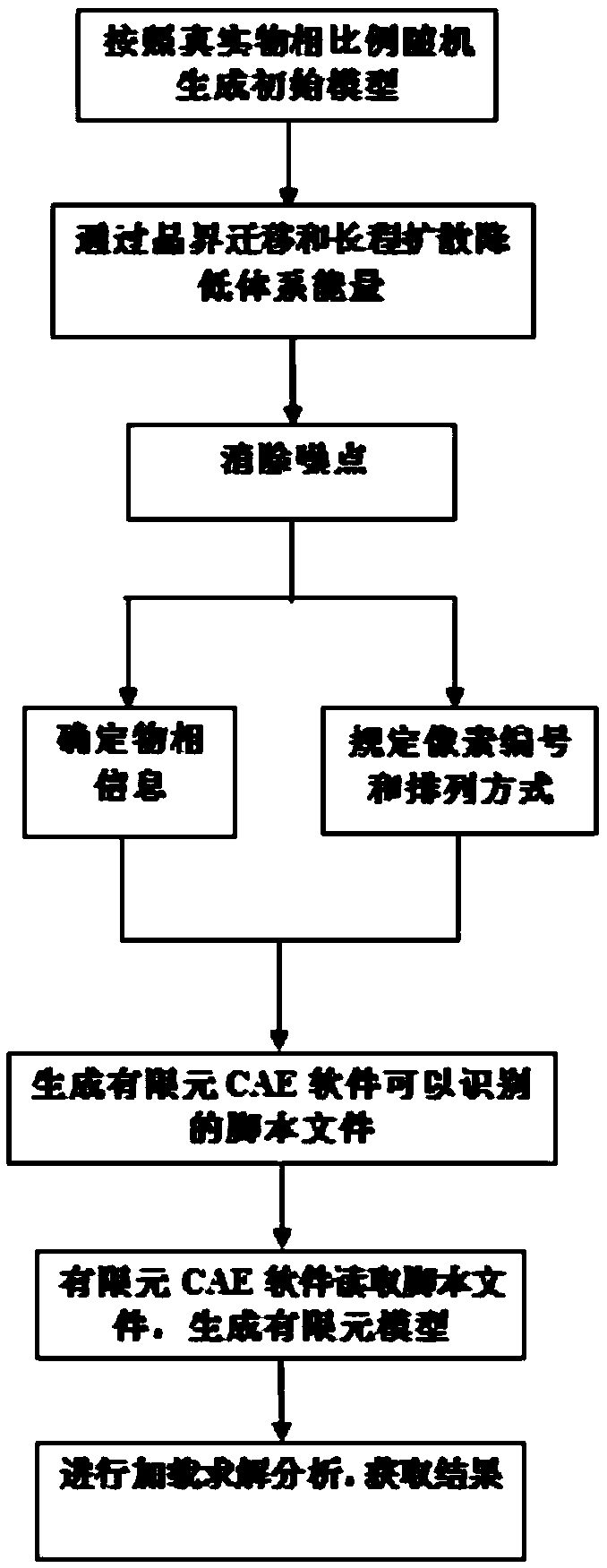

[0071] details as follows figure 1 As shown, the simulation of SnBi binary eutectic alloy microstructure and the finite element solution analysis method include the following steps:

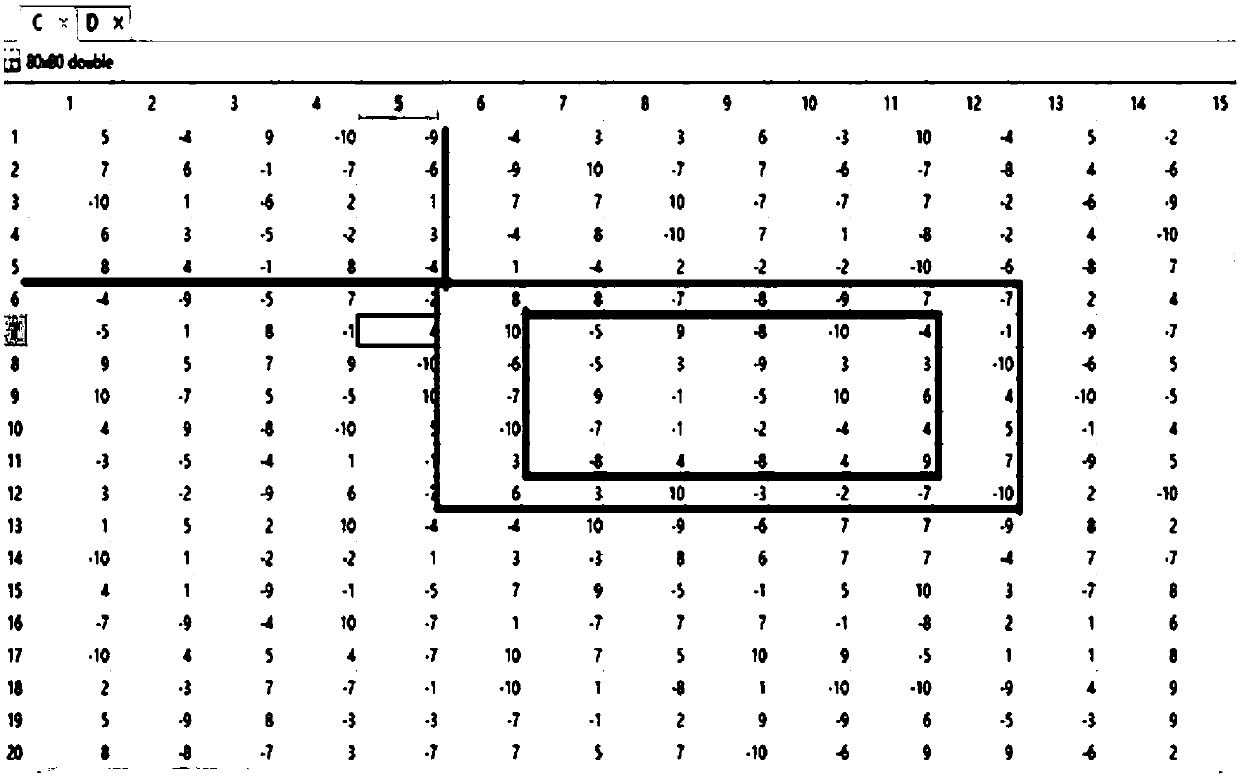

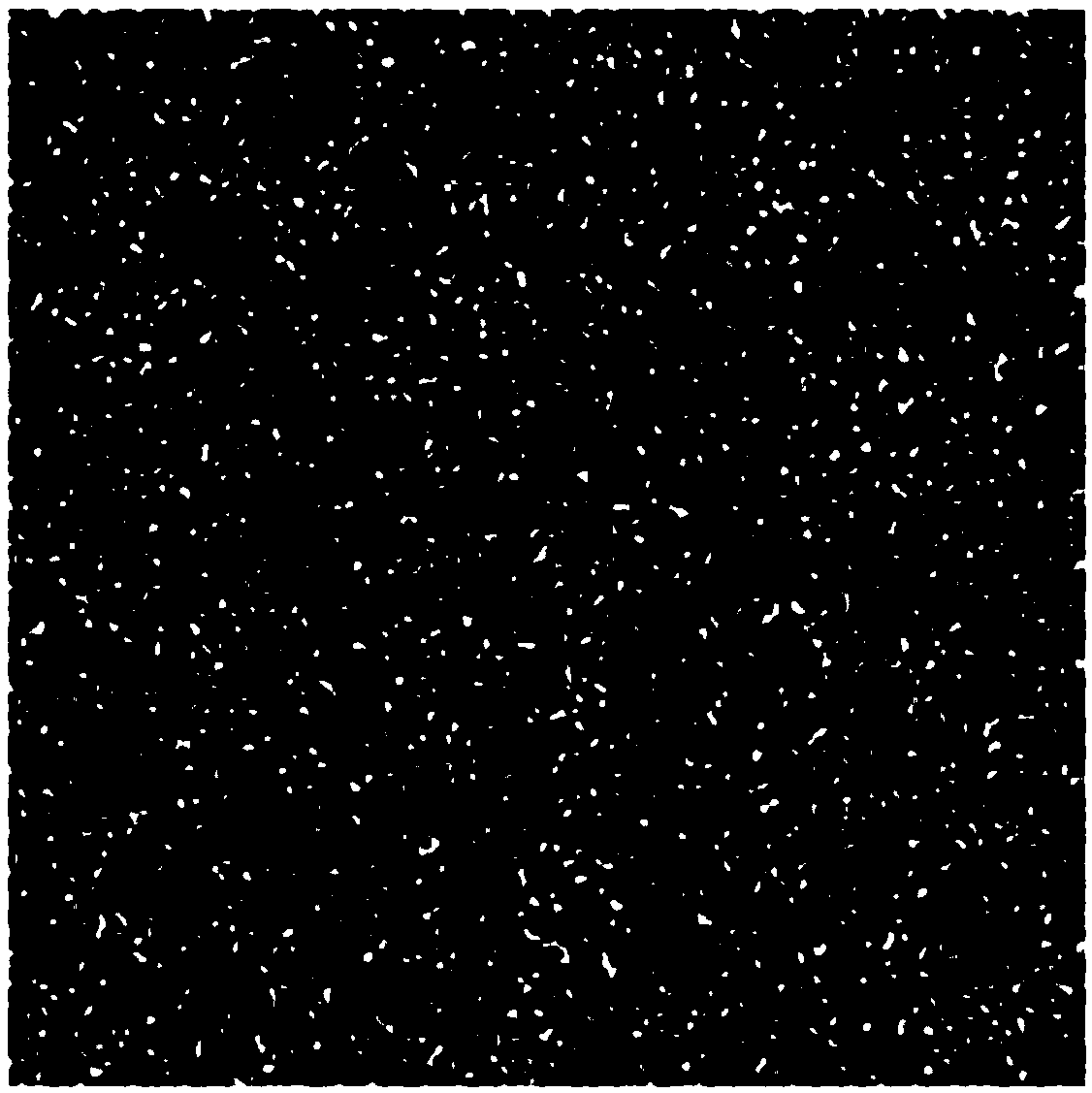

[0072] S1: Generate an initial model. The initial model consists of a 150×150 (i.e. m=150, n=150) array of sites, where the sites represent domains with lattice orientations, which are assigned random values between 1 and 10 or -1 and -10 (ie Q=10) to indicate the orientation of the grains. Sites representing the Sn phase are assigned positive orientations (i.e., 1 to 10). The site representing the Bi phase is assigned a negative integer in the interval from -10 to -1 (ie, -10 to -1); then the initial numerical model is randomly generated according to the phase ratio of the real object, because the two phases of SnBi in the eutectic structure The volume ratio is 1:1.03, the probability of Sn phase is 49.26%, and the probability of Bi phase is 50.74%. The generated random matrix is (partia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com