Intelligent energy-saving flexible mineral insulated fireproof cable with reduced size and processing method thereof

A mineral insulated and fireproof cable technology, applied in the direction of insulated cables, insulated conductors, cable/conductor manufacturing, etc., can solve the problems of difficult laying in small spaces of power distribution cabinets, large outer diameter of fireproof cables, and not soft laying, etc., to achieve excellent physical Excellent mechanical properties, excellent electrical properties, and excellent electrical insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is attached Figures 1 to 8 The given examples further illustrate the specific implementation of the size-reduced intelligent energy-saving flexible mineral insulated fireproof cable of the present invention. The size-reduced intelligent energy-saving flexible mineral insulated fireproof cable of the present invention is not limited to the description of the following embodiments.

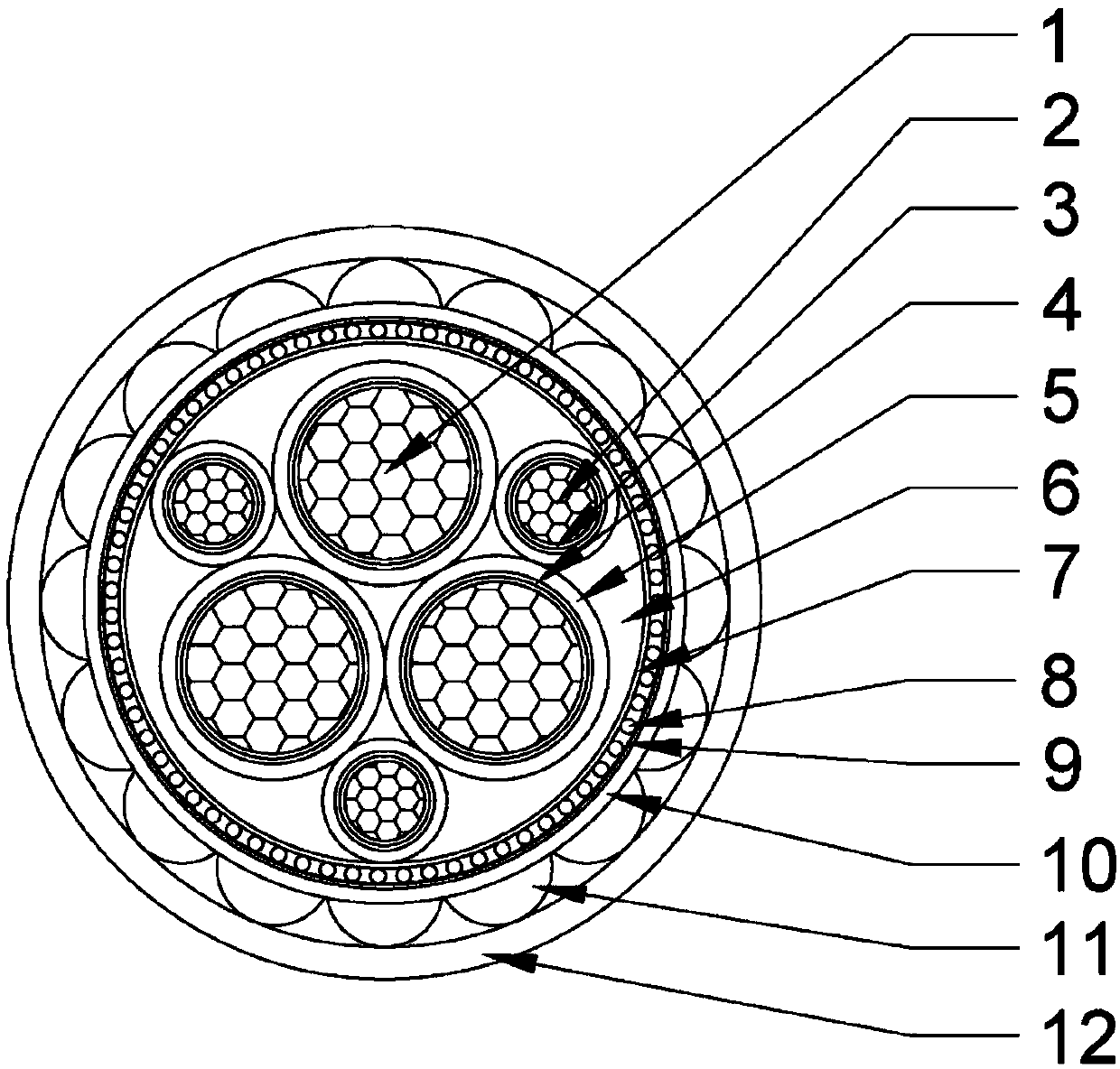

[0036] Such as figure 1 As shown, the present invention reduces the size of the smart energy-saving flexible mineral insulated fireproof cable, including the main core including the conductor 1 and the inorganic mineral insulating tape 3 wrapped around the conductor 1 in turn; the center core is wrapped around the conductor 2 in turn. The outer inorganic mineral insulation tape 3, the first halogen-free flame-retardant tape heat insulation layer 4 and insulation layer 5, the main core and center core 3+3 structure twisted into a cable and filled with inorganic mineral heat di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com