Thermal-insulating combined fire door

A fire-resistant door and fire-resistant skeleton technology, which is applied in the field of fire-resistant doors, can solve problems such as poor fire-proof performance, poor heat insulation, and easy deformation, and achieve the effects of reducing flame-retardant treatment, guaranteeing fire-proof and heat-insulation performance, and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

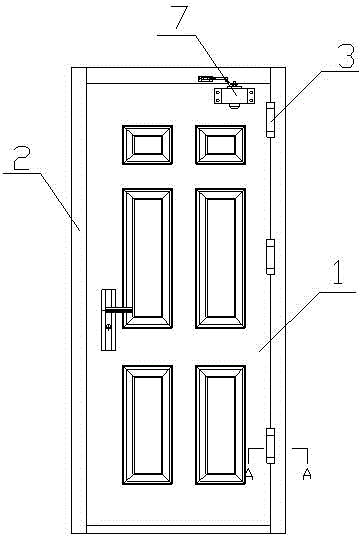

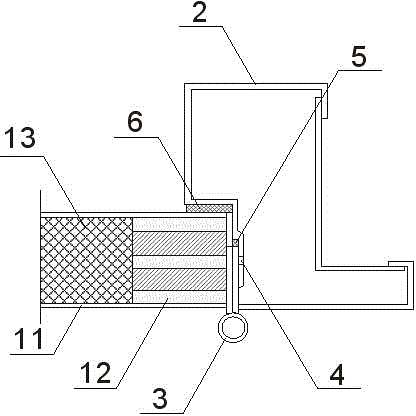

[0017] Example: see figure 1 , figure 2 , a heat-insulating composite fire door, comprising a door leaf 1, a door frame 2 and a hinge 3, one side of the door leaf 1 is hinged to the door frame 2 through a hinge 3, and the hinge 3 adopts a fireproof hinge 3; A fire-proof door closer 7 is also provided between the upper end of 2 and the upper end of the door leaf 1, through which the door leaf 1 can be closed in time to avoid the spread of fire and the diffusion of smoke. The door leaf 1 includes a frame body 11 formed by a face plate, a back plate and a side plate. In the frame body 11, a fire-proof frame 12 is respectively provided near the two side plates. The fire-proof frame 12 includes several fire-resistant plates parallel to the face plate. and the multi-layer boards located between the fire-resistant boards, the fire-resistant boards and the multi-layer boards are alternately distributed and bonded together by high-temperature-resistant glue. In the cavity formed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com