Semiconductor etching device

An etching equipment and semiconductor technology, which is applied in the manufacture of semiconductor/solid-state devices, discharge tubes, electrical components, etc., can solve the problems of easy adhesion of reaction products, cumbersome disassembly and assembly, etc., so as to increase the efficiency of irregular maintenance and improve the adhesion state , the effect of a wide range of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

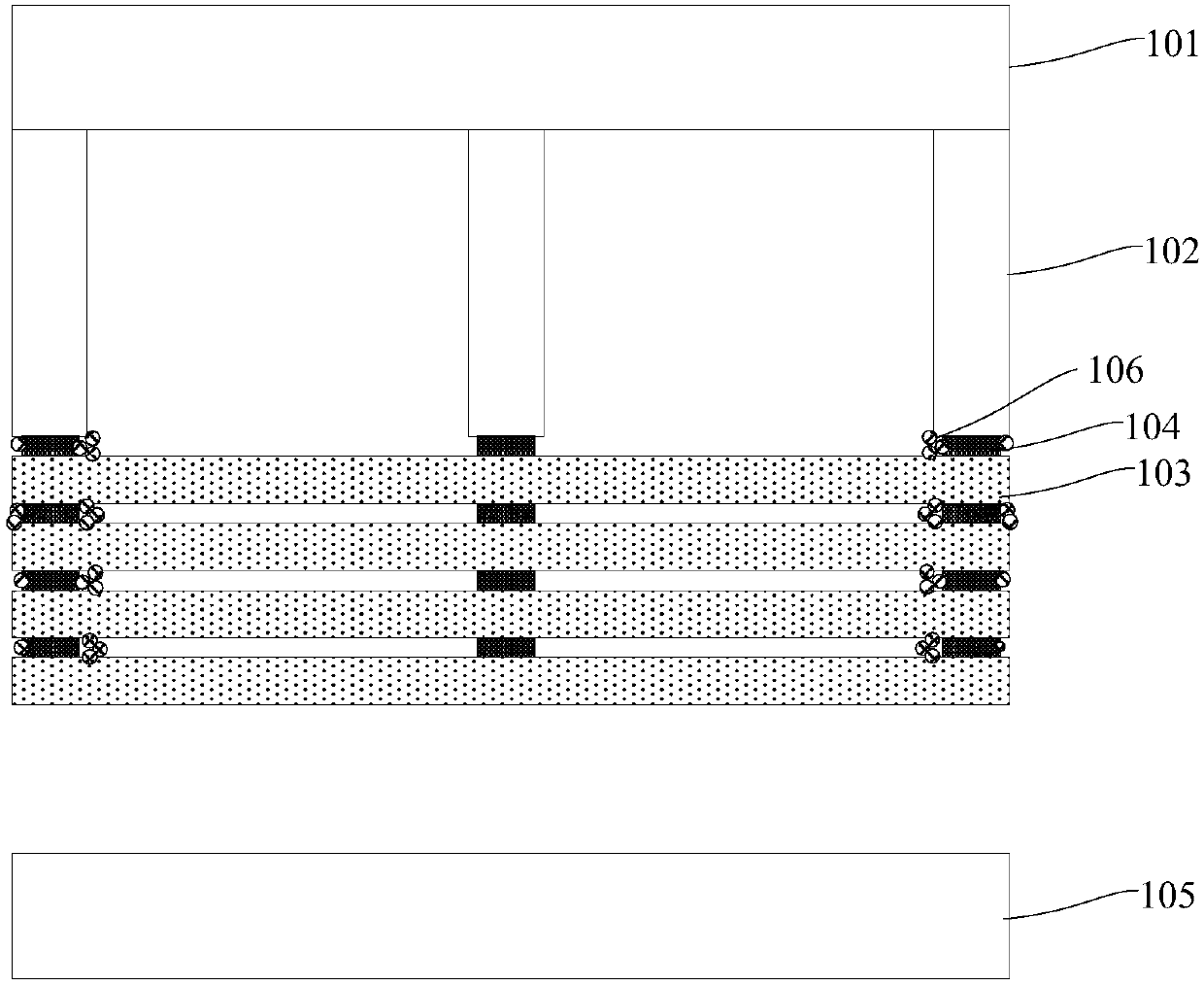

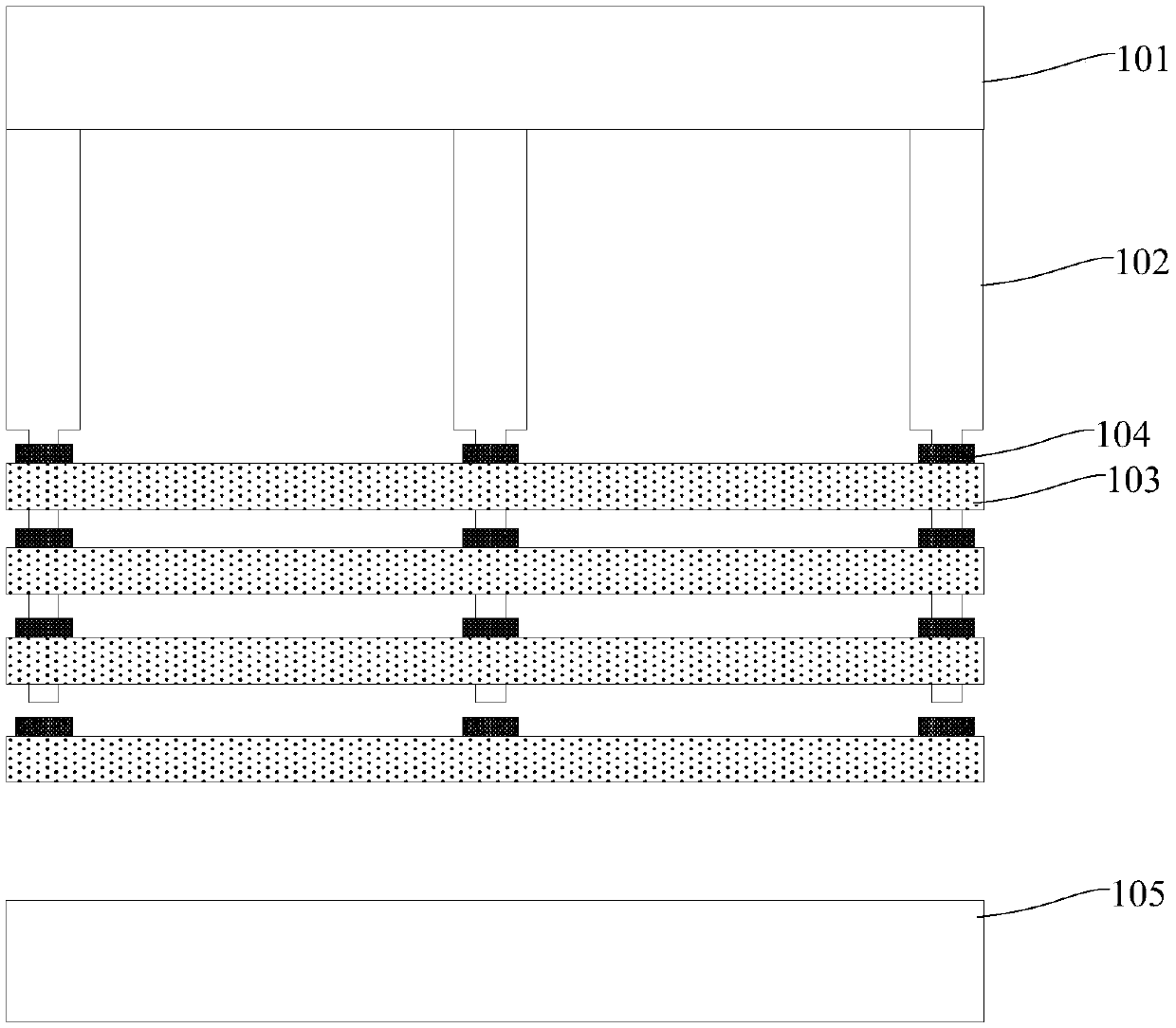

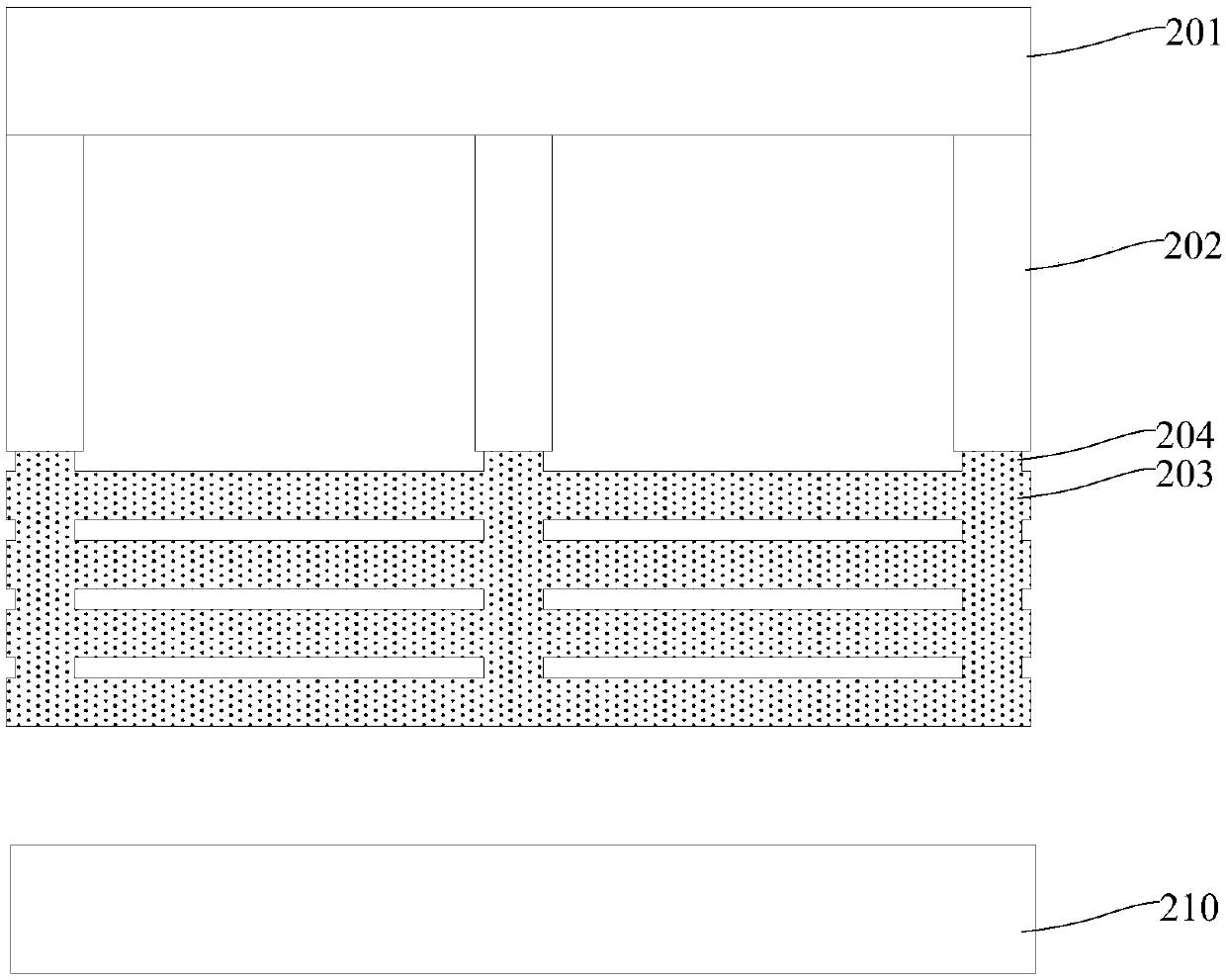

[0055] Such as Figure 3 ~ Figure 5 Shown, where, image 3 Shown as a schematic diagram of the assembly structure of the semiconductor etching equipment of this embodiment, Figure 4 A schematic diagram of the disassembly structure of the semiconductor etching equipment of this embodiment is shown, Figure 5 A cross-sectional view of the disassembled structure of the semiconductor etching equipment of this embodiment is shown. This embodiment provides a semiconductor etching equipment. The semiconductor etching equipment includes: an upper electrode spray plate 201 installed in the chamber of the semiconductor etching equipment to provide plasma gas; an annular side wall 202; The upper electrode spray plate 201; the side flow reaction element, which is connected to the annular side wall 202; and the lower electrode carrier 210, which is aligned below the side flow reaction element and is installed in the cavity of the semiconductor etching equipment Indoor; wherein, the lateral ...

Embodiment 2

[0066] Such as Figure 6 ~ Figure 7 Shown, where, Image 6 Shown as a cross-sectional view of the disassembled structure of the semiconductor etching equipment, Figure 7 Shown is a cross-sectional view of the assembly structure of the semiconductor etching equipment. This embodiment provides a semiconductor etching equipment, the basic structure of which is the same as that of Embodiment 1. The difference from Embodiment 1 is that the quartz ring 203 has a coupling hole 208 extending laterally outward, and the annular side wall The positioning post 205 has a locking hole 206 corresponding to the position of the combining hole 208. When the positioning post 205 is combined with the positioning groove 207, the combining hole 208 and the locking hole 206 are aligned with each other and limit the position. The pin 209 is passed through to prevent the positioning column 205 from sliding relative to the positioning groove 207, that is, to prevent the lateral flow reaction element fr...

Embodiment 3

[0070] This embodiment provides a semiconductor etching equipment, the basic structure of which is the same as that of Embodiment 1. The difference from Embodiment 1 is that the bottom surface of the annular side wall 202 has a plurality of positioning grooves 207, and the quartz The ring 203 has a plurality of positioning posts 205 corresponding to the positioning grooves 207, and the positioning posts 205 are combined with the positioning grooves 207 to achieve a fixed connection between the quartz ring 203 and the annular side wall 202. Further, the annular side wall 202 has a coupling hole 208 extending laterally outward, and the positioning post 205 has a locking hole 206 corresponding to the position of the coupling hole 208. When the positioning post 205 and the positioning groove 207 are After the combination, the coupling hole 208 and the clamping hole 206 are aligned with each other and are connected by a stop pin 209 to prevent the positioning post 205 from sliding re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com